Ball valve suitable for gas-liquid two-phase flow

A gas-liquid two-phase flow, ball valve technology, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of complicated installation and disassembly, restrictions on the use of ball valves, and increasing the number of components in the pipeline system, reducing Installation and maintenance costs, increased fluid flow rates, reduced installation effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

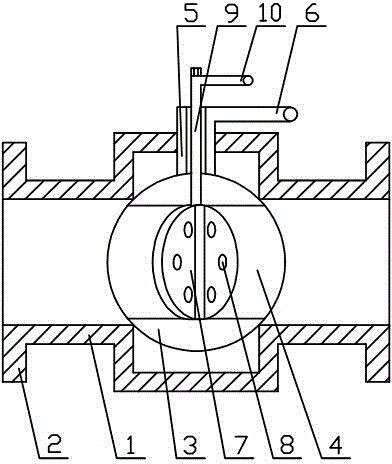

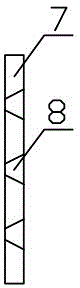

[0014] The present invention includes a valve body 1, a connecting flange 2, a valve core 3, a flow channel 4, a valve stem 5, a switch handle 6, a fluidization inner core 7, a fluidization hole 8, an adjustment rod 9, and a fluidization adjustment handle 10. When installing the connection flange 2 at both ends of the valve body 1, the flow passage 4 is opened on the valve core 3, the fluidization hole 8 is opened on the fluidization inner core 7, and then the fluidization inner core 7 is installed on the circulation passage 4 Then install the valve core 3 inside the valve body 1, and finally install the regulating rod 9 on the inside of the valve stem 5, connect the lower end of the regulating rod 9 with the fluidizing inner core 7, and connect the upper end of the regulating rod 9 with the flow The adjustment handle 10 is connected, the lower end of the valve stem 5 is connected with the valve core 3, and the upper end of the valve stem 5 is connected with the switch handle 6...

Embodiment 2

[0016] When in use, turn the switch handle 6 to connect the flow channel 4 with the pipeline, and adjust the opening of the fluidization inner core 7 by rotating the fluidization adjustment handle 10, so as to achieve the effect of adjusting the fluidization degree, and the gas-liquid two-phase fluid enters the valve The body 1 enters the valve core 3 from the flow passage 4, and then flows out of the valve body 1 after being fluidized by the fluidizing inner core 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com