Tunnel seepage instability model test device and test method with ground pressure and water pressure controllable

A model test device, hydraulic technology, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of osmotic instability mechanism hysteresis, high cost requirements, large size, etc., to achieve enhanced Scientific value, improved airtightness, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

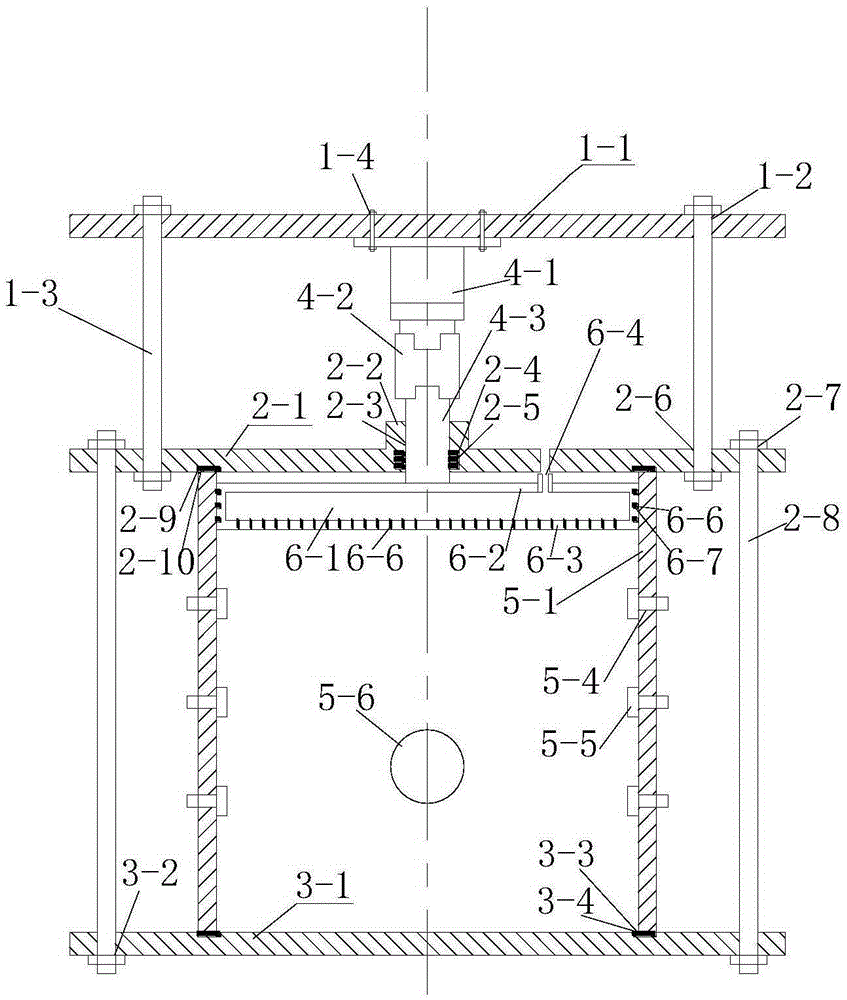

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

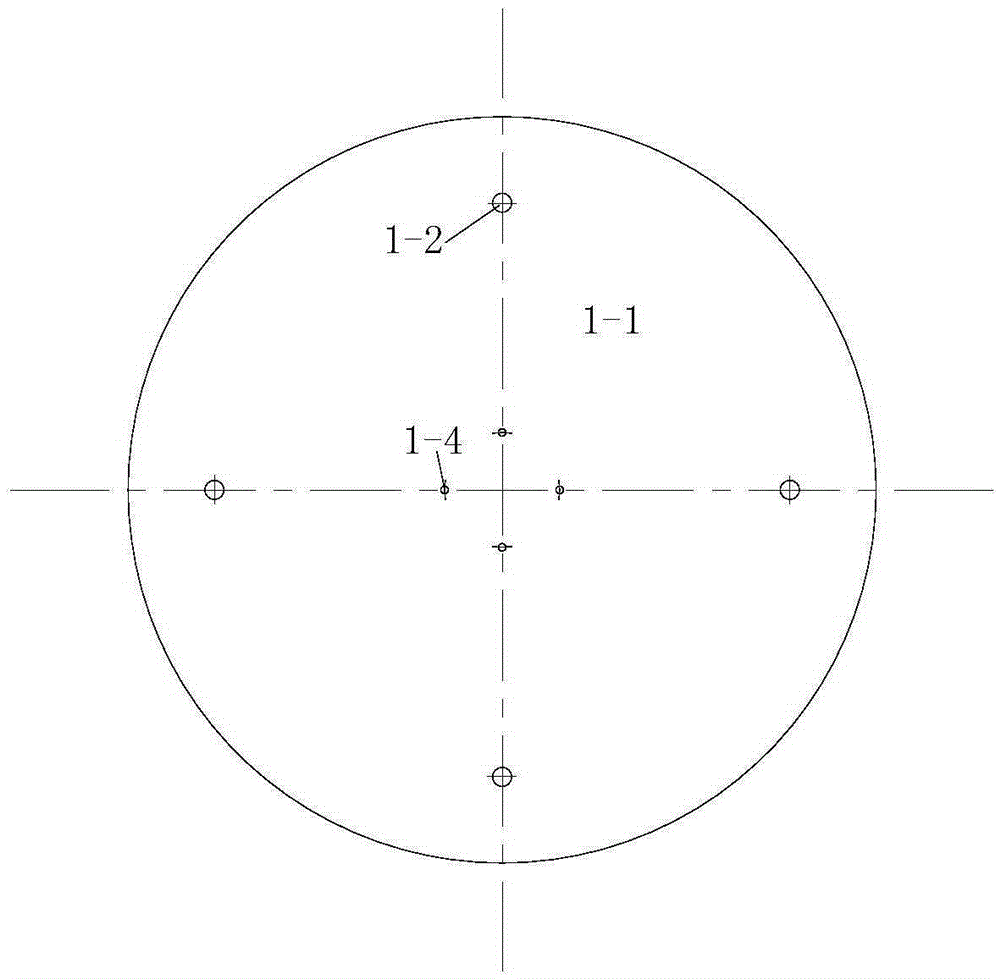

[0047] Such as figure 1 , figure 2 As shown, the first high-strength pressure bearing plate 1-1 is processed into a Φ780*25mm (diameter 780mm, height 25mm) disc made of high-strength alloy steel. Four symmetrically distributed Φ20mm fixing holes I1-2 are drilled on the Φ600mm circumference of the pressure plate to allow the fastening screw I1-3 to pass through. Fastening screw rod 1 is 4 high-strength screw rods of Φ16mm, which connects the first high-strength pressure bearing plate 1-1 and the second high-strength pressure bearing plate 2-1. Four Φ4mm hydraulic cylinder fixing holes 1-4 are evenly distributed on the Φ120mm circumference below the first high-strength pressure bearing plate to fix the hydraulic cylinder.

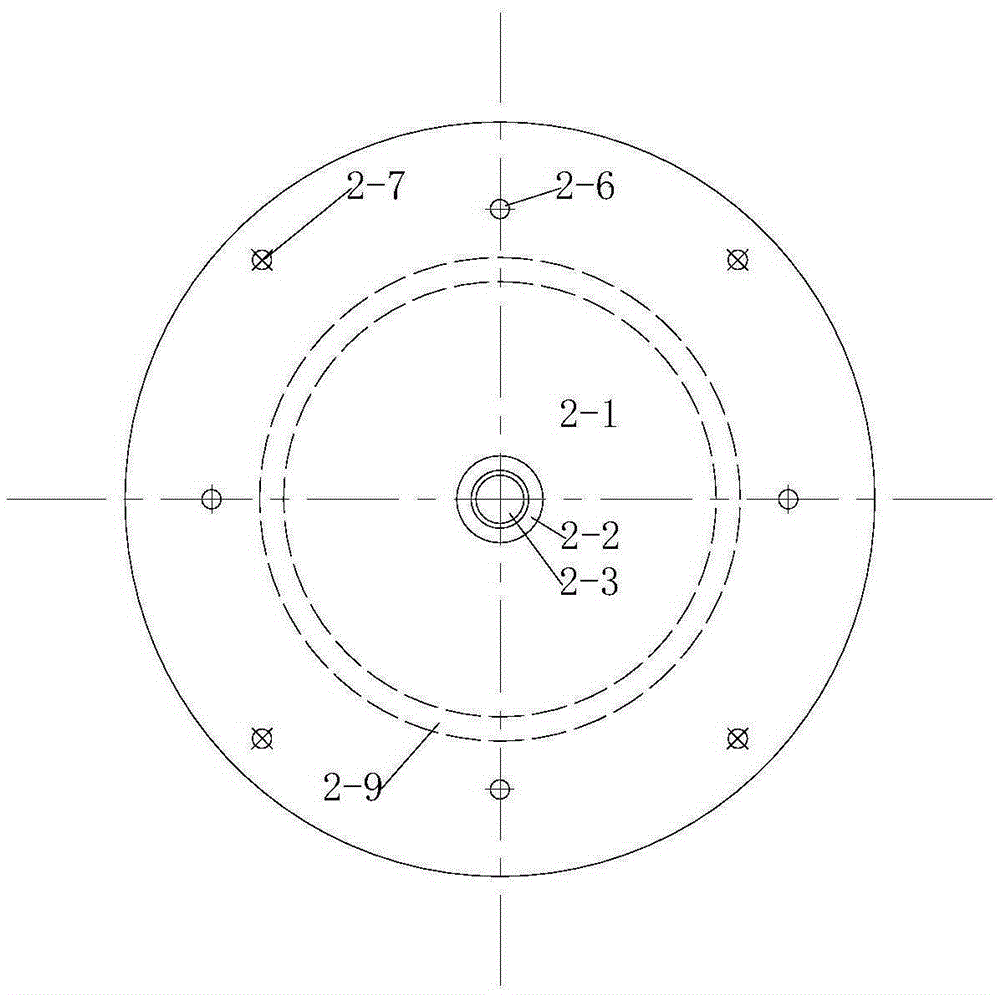

[0048] Such as figure 1 , image 3 As shown, the second high-strength pressure bearing plate 2-1 is processed into a Φ780*25mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com