Test and control method of material testing machine

A technology of material testing machine and measurement and control method, which is applied in the field of measurement and control, can solve the problems of high investment and maintenance costs, cumbersome system wiring, poor system scalability and mobility, etc., and achieve the effect of simple method and cumbersome wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

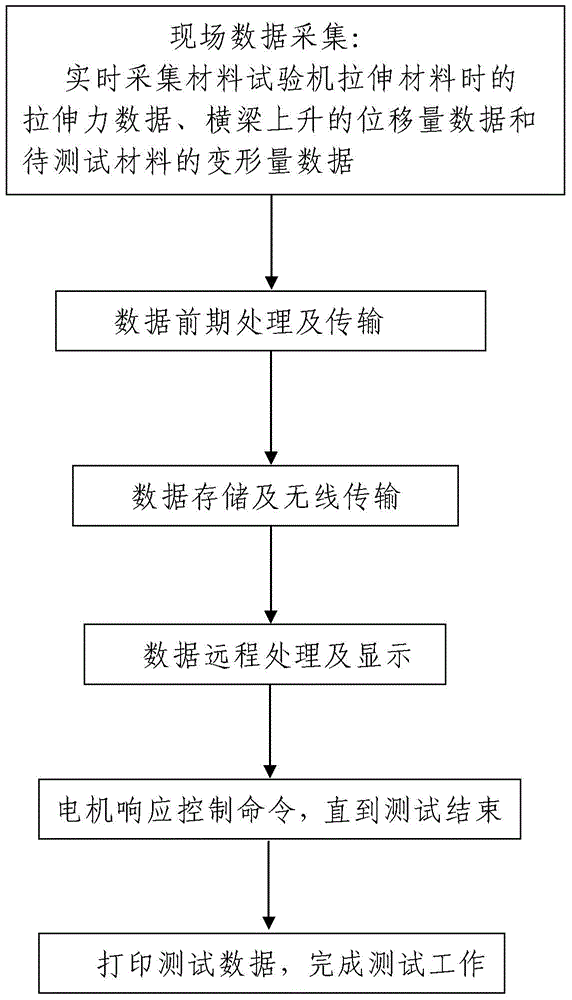

[0019] like figure 1 As shown, the present invention comprises the following steps:

[0020] Step 1, on-site data collection: use the sensor unit installed on the material testing machine to collect the working parameters of the material testing machine; A motor that drives the lead screw to drive the beam to move up and down and a controller mounted on the base; the sensor unit includes a load sensor fixed on the base and a displacement sensor located at the top of the lead screw and a deformation sensor installed on the test piece fixture; the controller includes a central processing unit, a memory, a data acquisition card, a signal conditioning circuit, a first photoelectric isolator and a second photoelectric isolator, the memory, data acquisition Both the card and the signal conditioning circuit are connected to the central processing unit, the first photoelectric isolator is respectively connected to the load sensor and the signal conditioning circuit, and the second ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com