Pumping Well Data Acquisition Control System and Its Method Based on Wireless Network

A technology for pumping wells and control methods, applied in general control systems, control/regulation systems, program control, etc., can solve the problem of inability to guarantee the timely and accurate monitoring data throughout the day, low success rate of wireless communication, and poor construction and maintenance. Convenience and other issues to solve problems that are not conducive to maintenance, ensure data reliability, and optimize on-site wiring and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

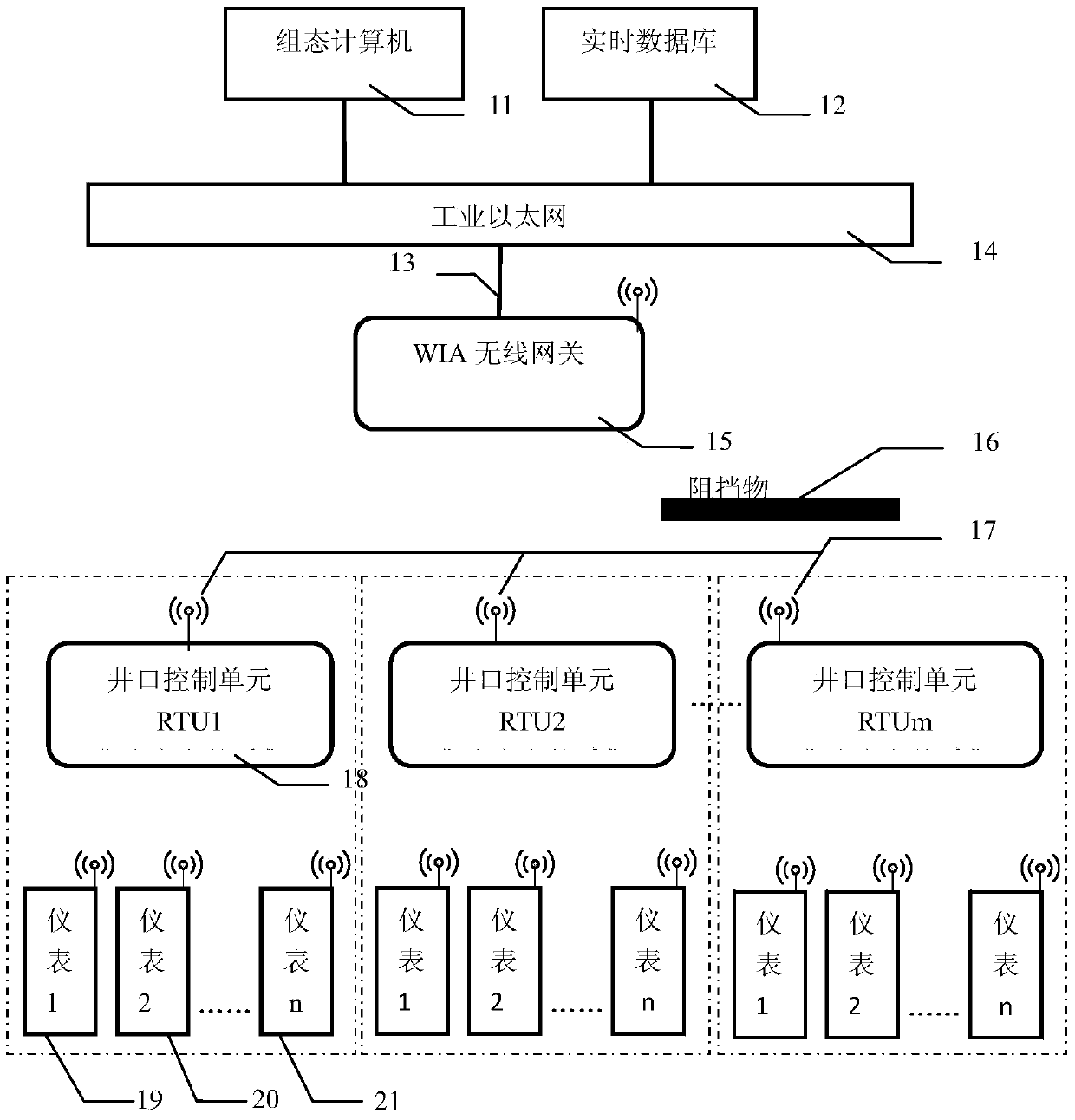

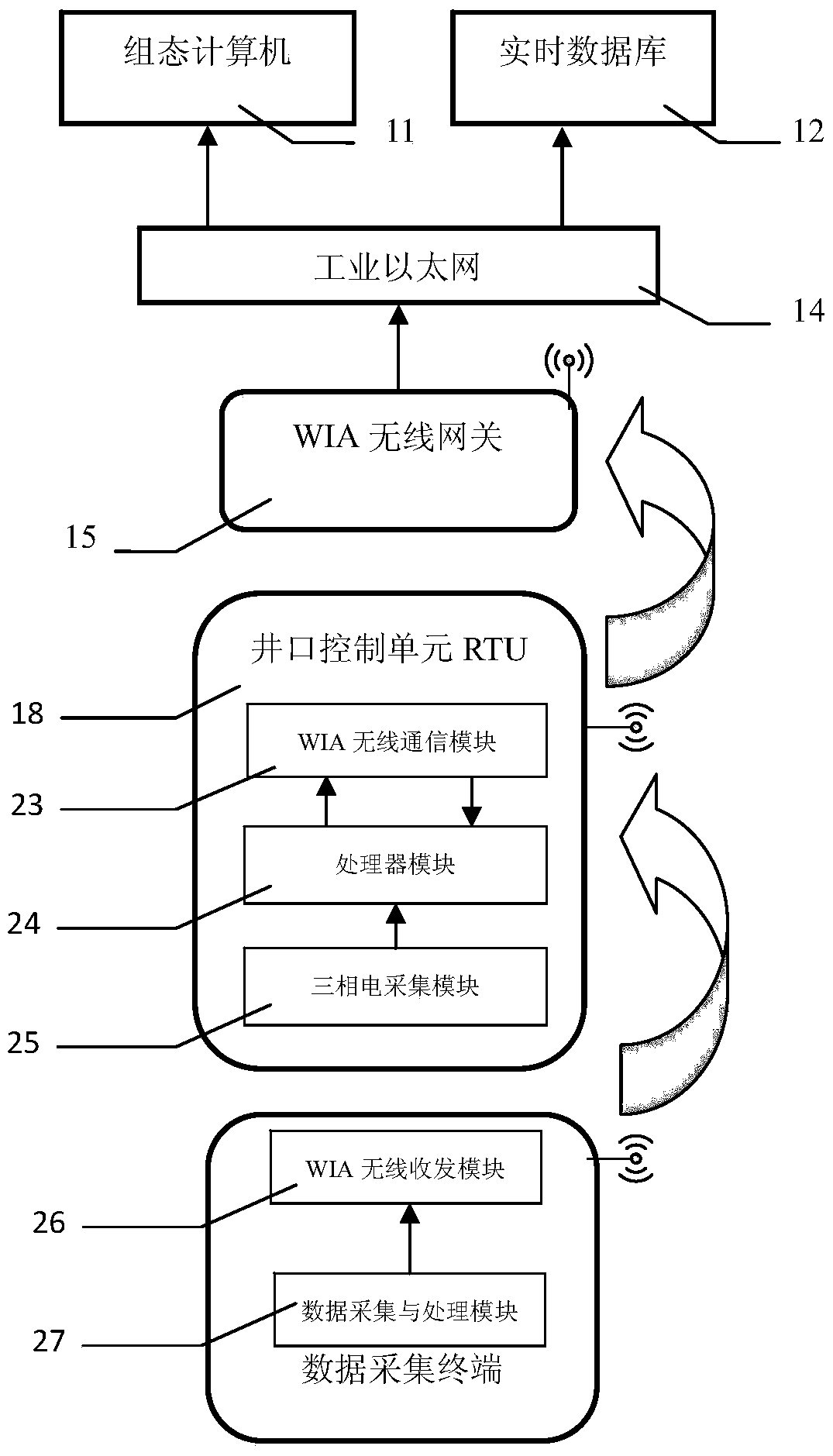

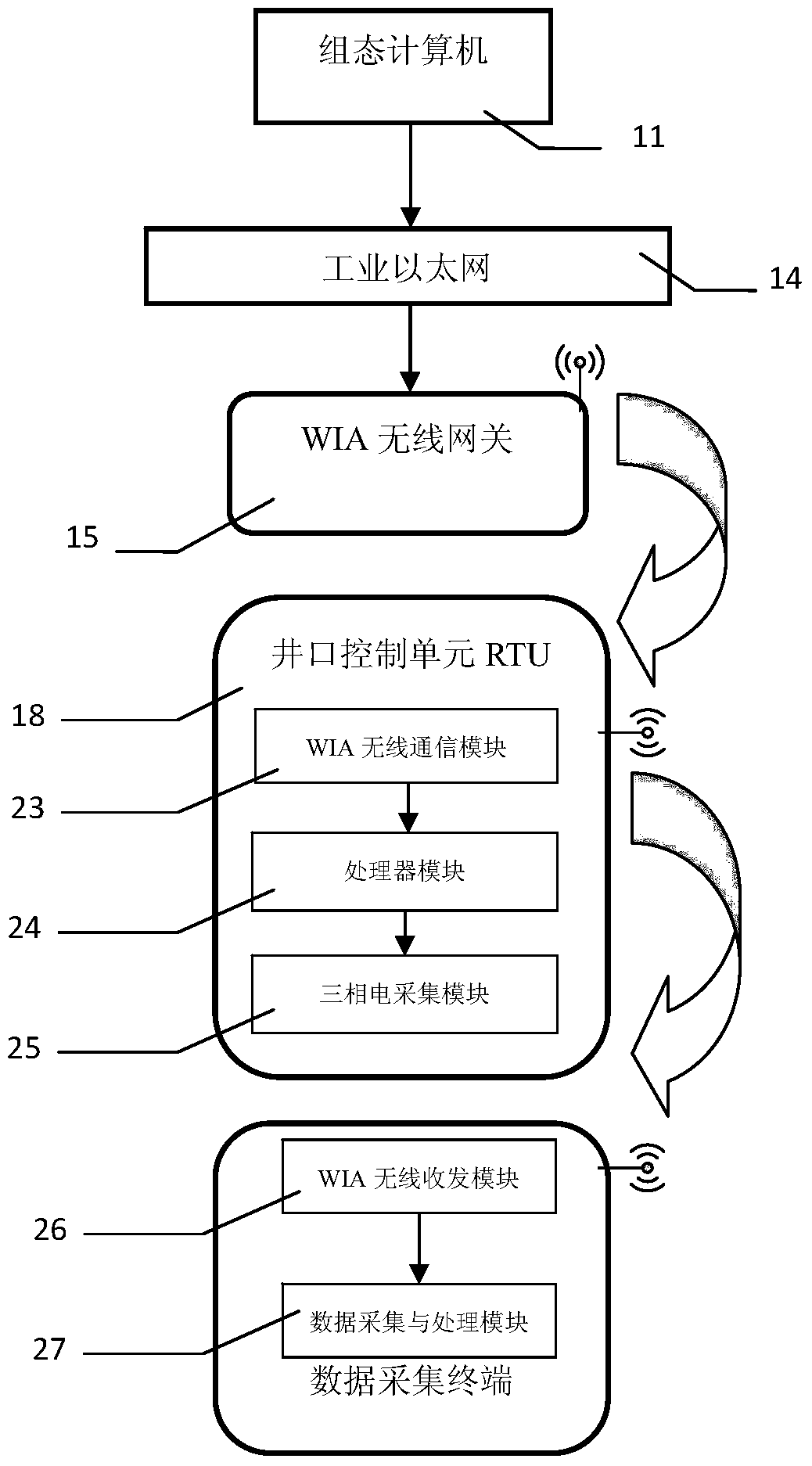

[0043]The pumping well data acquisition and control system based on the WIA-PA intelligent wireless network fully realizes the automatic acquisition and control function of the oil and gas production Internet of Things production data. The data acquisition terminal installed at the wellhead transmits the automatically collected real-time production data to the wellhead control unit RTU through sensing and radio frequency communication technology, and the RTU (REMOTE TERMINAL UNIT) stores and transmits the data to the central control room through the WIA wireless gateway; at the same time, the central The remote control commands issued by the control room are sent to the wellhead control unit RTU through the WIA wireless gateway, and the RTU executes the control commands or sends them to the wireless acquisition terminal.

[0044] The system is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com