Genetic algorithm-based advanced plan scheduling system and method

A genetic algorithm, planning and scheduling technology, applied in the direction of manufacturing computing systems, calculations, instruments, etc., can solve problems such as difficult planning and scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

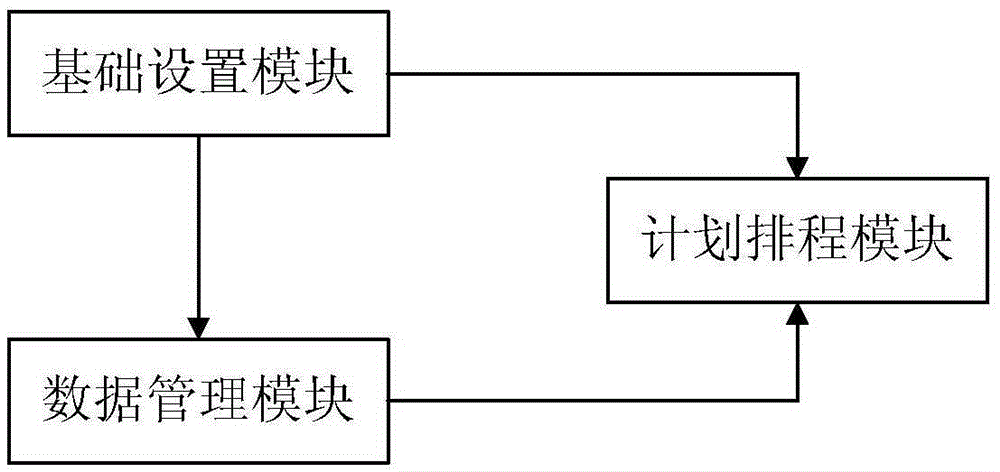

[0033] Such as figure 1 As shown, the present invention includes a basic setting module, a data management module, and a planning and scheduling module.

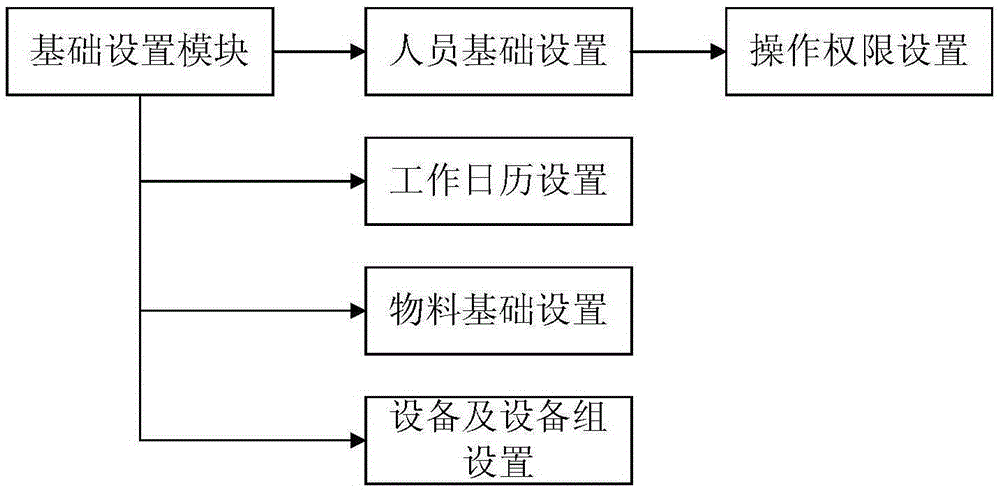

[0034] Such as figure 2 As shown, the specific realization of the basic setting module in the present invention is as follows:

[0035] 1) Material settings for workshop or factory production and processing, including material code, name, main production department, and other attribute information;

[0036] 2) Information setting of personnel in the system, including information setting of personnel code, personnel attribute, and subordinate department;

[0037] 3) Set the team information contained in the production department, including team code, team name, and team attribute settings;

[0038] 4) The working calendar setting of the workshop or factory, including the designation of working days and non-working days, different departments can set different working calendars;

[0039]5) Set operation authority for syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com