Multi-plane-mirror reflection tracking pan-tilt system calibration method

A calibration method and plane mirror technology, applied in image data processing, instrumentation, calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described through specific implementation examples below in conjunction with the accompanying drawings.

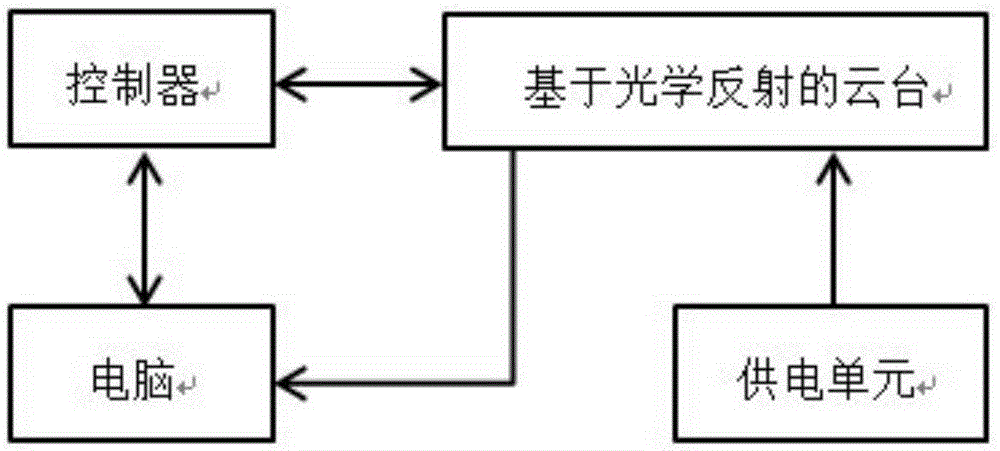

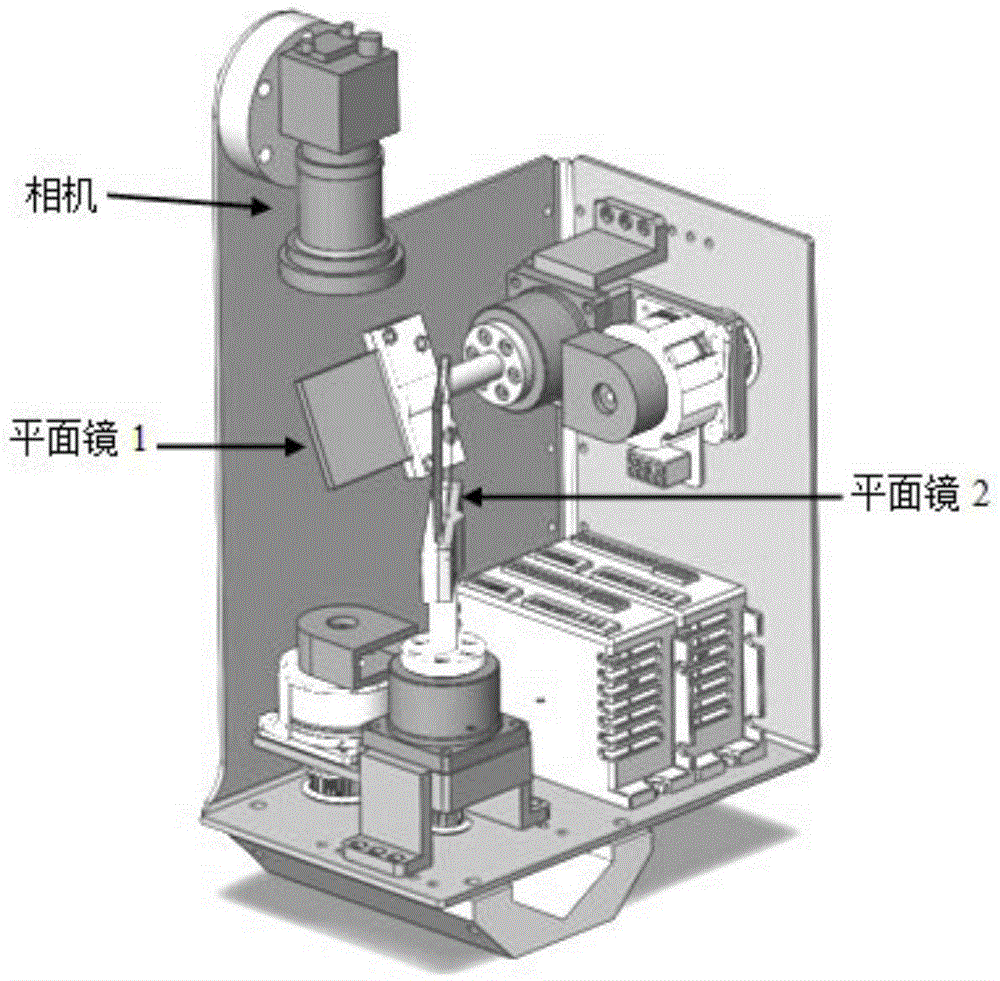

[0027] figure 1 It is a structural schematic diagram of the system of the present invention. The system is a pan-tilt visual tracking system based on optical reflection. The system includes a pan-tilt based on optical reflection, a controller, a computer, and a power supply unit. The controller is connected to receive instructions from the controller and feed back the state of the rotary drive unit. The controller is connected to the computer to receive instructions and feedback status. The pan / tilt based on optical reflection is also connected to the computer to transmit the images collected by the camera to the computer. The optically reflective pan / tilt is connected to a power supply unit.

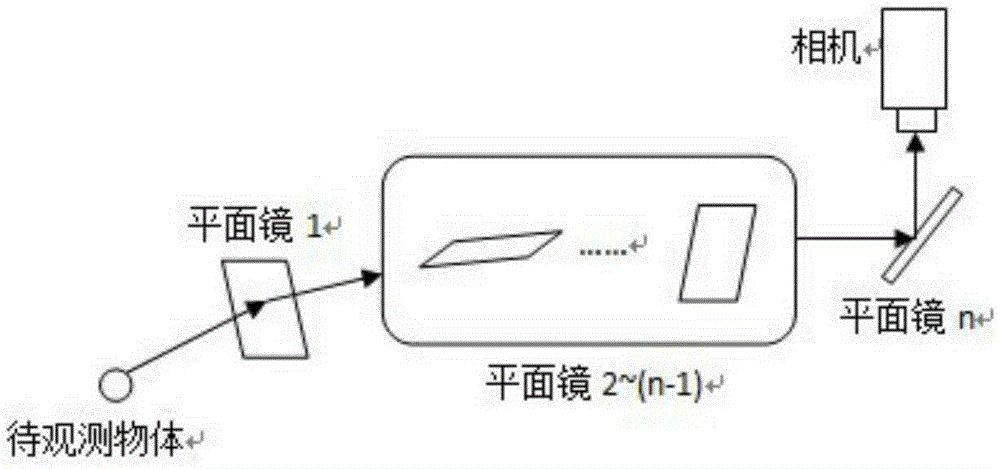

[0028] figure 2 It is a schematic diagram of a pan / tilt based on optical reflection (n≥2) using n plane mir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com