Ultra small and ultrathin high luminous efficiency lateral emission type high light white light polycrystalline LED element

A high-efficiency, LED chip technology, used in electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of insufficiency, large size, inability to miniaturize, etc., to reduce product size, improve heat dissipation, and save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

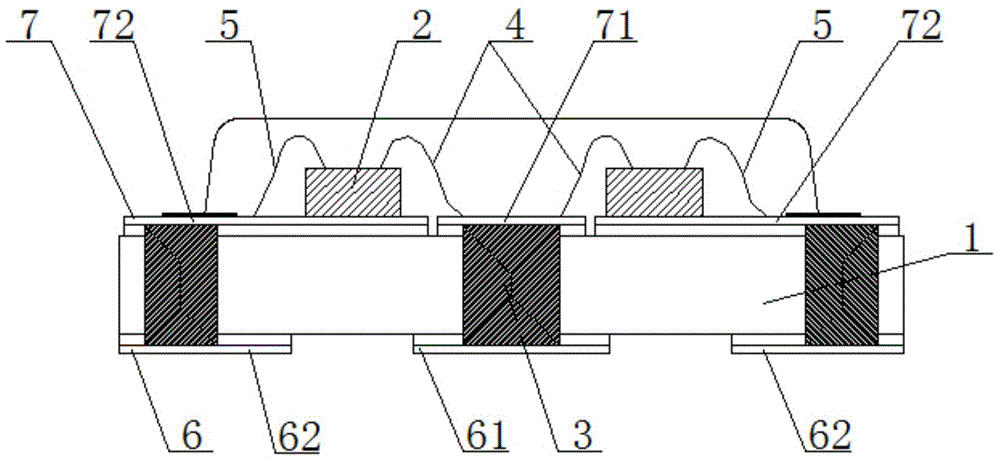

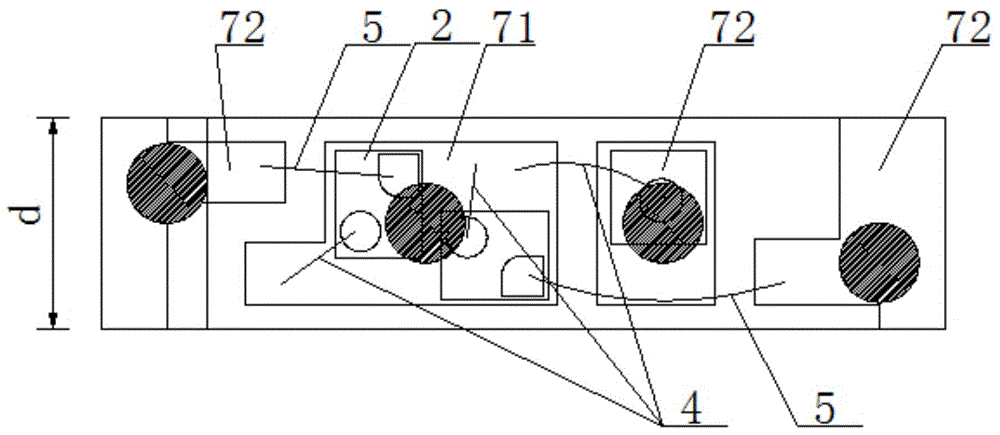

[0036] Preferred embodiment one: as figure 1 There are two light-emitting LED chips 2 shown, and the positive wires 4 of the two light-emitting LED chips 2 are welded to the positive region 71 in the middle, and the two negative wires 5 are respectively connected to two mutually independent negative regions 72 on both sides. welding. The ultra-small, ultra-thin, high-efficiency side-firing high-brightness white light twin-crystal LED element is rectangular: its length is 1.6±0.2mm, its width is 0.6±0.2mm, and its thickness d is 0.3±0.1mm. Preferably: length 1.6mm, width 0.6mm, thickness 0.3mm.

Embodiment 2

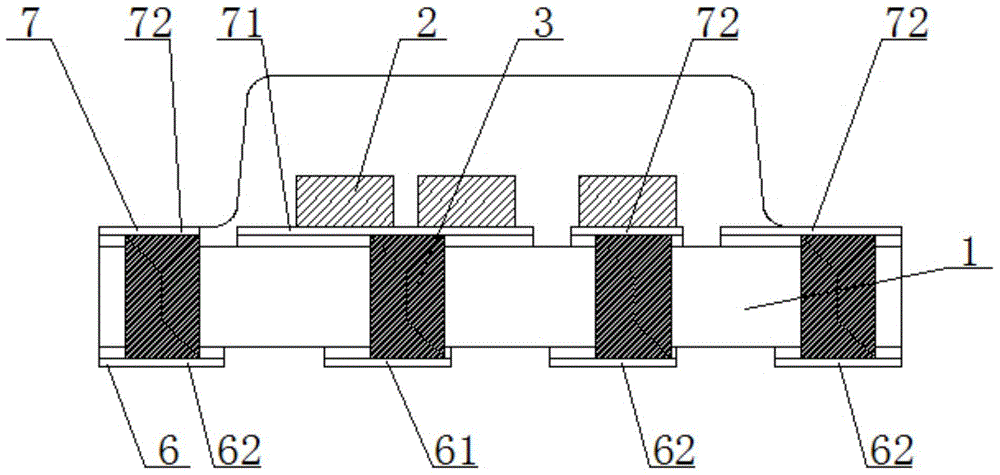

[0037] Preferred embodiment two: as figure 2 , 3 There are three light-emitting LED chips 2 shown, and the positive wires 4 of the three light-emitting LED chips 2 are all welded to the positive region 71 in the middle, and the three negative wires 5 are respectively welded to three mutually independent negative regions 72 on both sides. . The ultra-small, ultra-thin, high-efficiency side-firing high-brightness white three-crystal LED element is rectangular: its length is 1.6±0.2mm, its width is 0.6±0.2mm, and its thickness d is 0.4±0.1mm. Preferably: length 1.6mm, width 0.6mm, thickness 0.4mm.

[0038] A process for preparing an ultra-small, ultra-thin, high-efficiency side-firing high-brightness white polycrystalline LED element, the steps are as follows:

[0039] a. Prepare raw materials: Drill through holes on the PCB substrate 1 and conduct the upper and lower bottom surfaces of the PCB substrate 1 through the copper plugging process to form the plug hole copper pilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com