Automatic discharging device of upper discharging centrifugal machine

An automatic discharge device and centrifuge technology, applied in the field of centrifuges, can solve the problems of lack of automation and manual operation of electric hoists, and achieve the effects of saving space and cost, simple structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The automatic discharge device of an upper discharge centrifuge according to the present invention will be further described in detail through specific embodiments below.

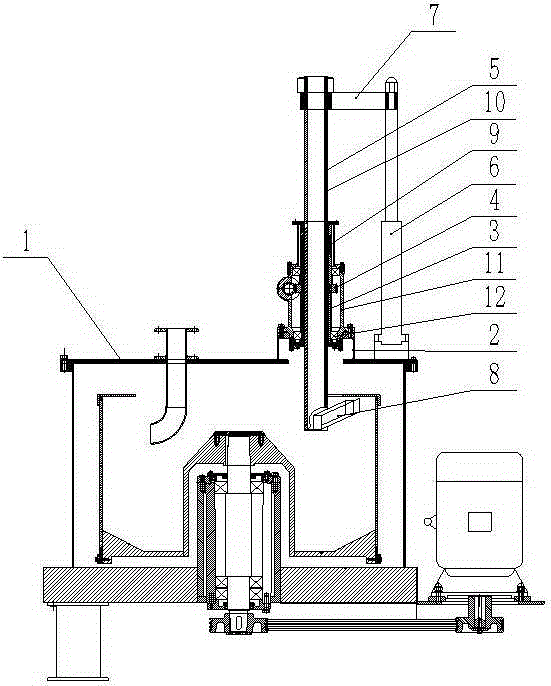

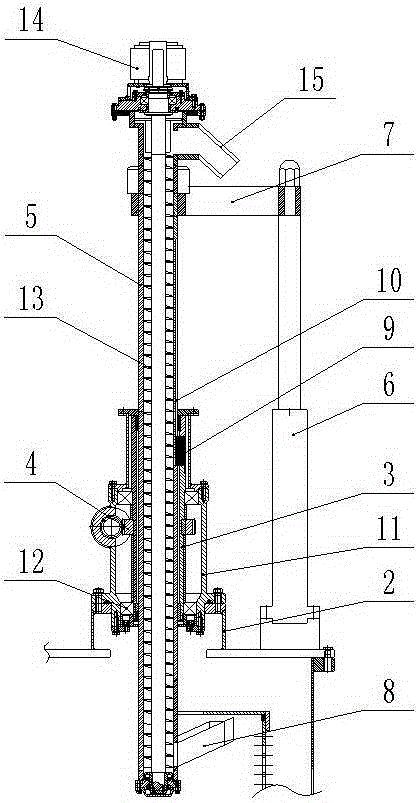

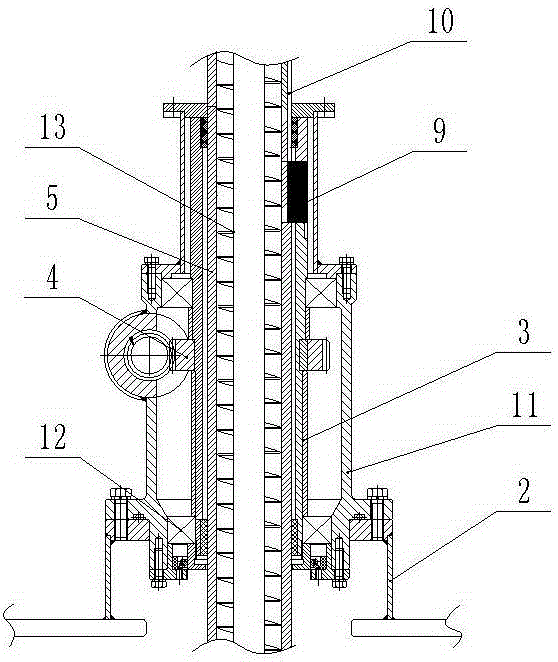

[0017] like figure 1 , image 3 As shown, the automatic discharge device of the upper discharge centrifuge includes a bracket 2 arranged on the centrifuge casing cover 1, and the bracket 2 is provided with a rotatable rotating sleeve 3 and a rotating shaft that drives the rotating sleeve 3 to rotate. Driving device. In this embodiment, the rotating driving device includes a rotating gear 4 arranged outside the rotating sleeve 3, and the rotating gear 4 is connected with a rotating oil cylinder (not shown in the figure) through a rack. The structure of the rotary driving device can also adopt other traditional driving methods, which all belong to the protection category of the present invention. The rotating sleeve 3 is provided with a lifting tube 5 that can move in the axial direction, and the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com