Vaporific parting liquid separation mold device

A liquid separation and mist technology is applied in the field of mist separation liquid separation mold device, cold core box core shooter sand core and mold separation production process, which can solve the problems of high labor intensity, non-automation, low efficiency, etc. Achieve the effect of improving work efficiency, reasonable structure and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

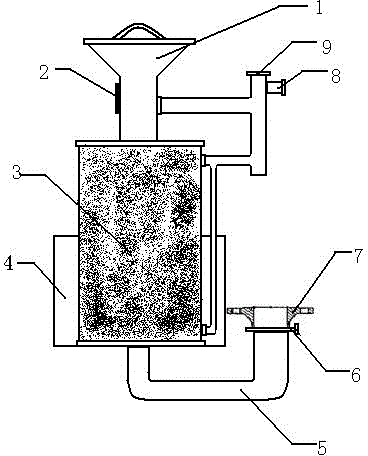

[0011] This embodiment provides a mist type liquid separation mold device, characterized in that: the mist type liquid separation mold device includes a liquid injection funnel (1), a flow meter (2), a tank (3) , support seat (4), high pressure air pipe (5), pressure regulating valve (6), flange (7), nozzle (8), opening regulating valve (9);

[0012] Among them: the device tank (3) is fixed on the support base (4), the tank body (3) is provided with a typing liquid injection funnel (1), and the lower end of the tank body (3) is provided with a high-pressure air pipe (5), The high-pressure air pipe (5) is connected to the external high-pressure air source, and the connection is provided with a flange (7) and a pressure regulating valve (6). A flow meter (2) for controlling the flow is provided under the liquid injection funnel (1). One side communicates with the nozzle (8), and the nozzle (8) is provided with an opening regulating valve (9).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com