Technology for enabling passengers to get on and get off train without stopping in station

A technology for trains and technology, applied in the field of non-stop loading and unloading of trains, can solve problems such as equipment loss, time and energy waste, and achieve the effects of reducing train loss, saving energy, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

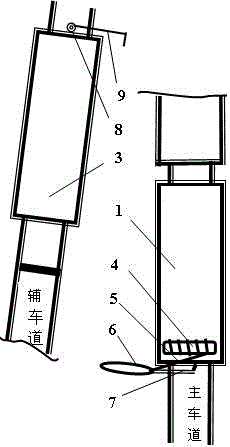

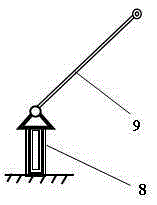

[0021] The implementation process of the invention will be described below in conjunction with the accompanying drawings.

[0022] The technology for getting on and off the train without stops includes a main car 1, a passenger compartment 2, a passenger compartment 3, a hoist 4, a steel cable 5, a collar 6, a support 7, a traction column 8, a connecting rod 9, and a main driveway 10 and the auxiliary lane 11; before the main car 1 enters the station, the passengers getting off are transferred from each compartment of the main car 1 to the passenger compartment 2 at the rear of the car in an orderly manner in advance; luggage, mail and other various things that need to be unloaded also Together, the staff will transfer them to the passenger compartment 2; when the main vehicle 1 travels along the main lane 10 to a certain position near the station, the passenger compartment 2 will separate from the main vehicle 1 according to the instructions of the operator on the main vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com