Signal acquisition circuit, signal acquisition device and signal acquisition system applicable to magnetic steel online fault diagnosis

A technology for fault diagnosis and circuit acquisition, applied in railway signaling, railway signaling and safety, transportation and packaging, etc., can solve problems such as sacrificing data accuracy, misjudgment, and reduced detection sensitivity of wheel sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

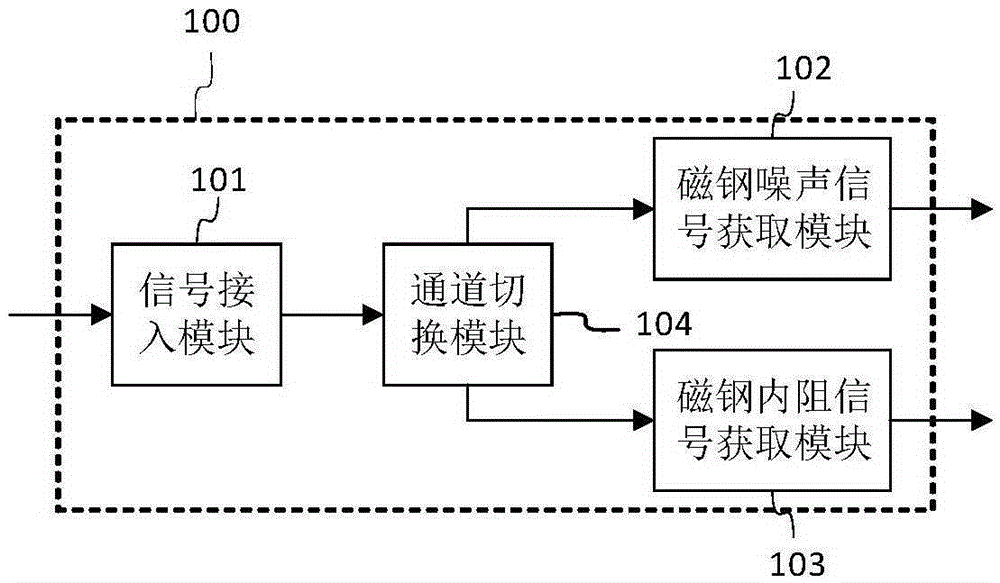

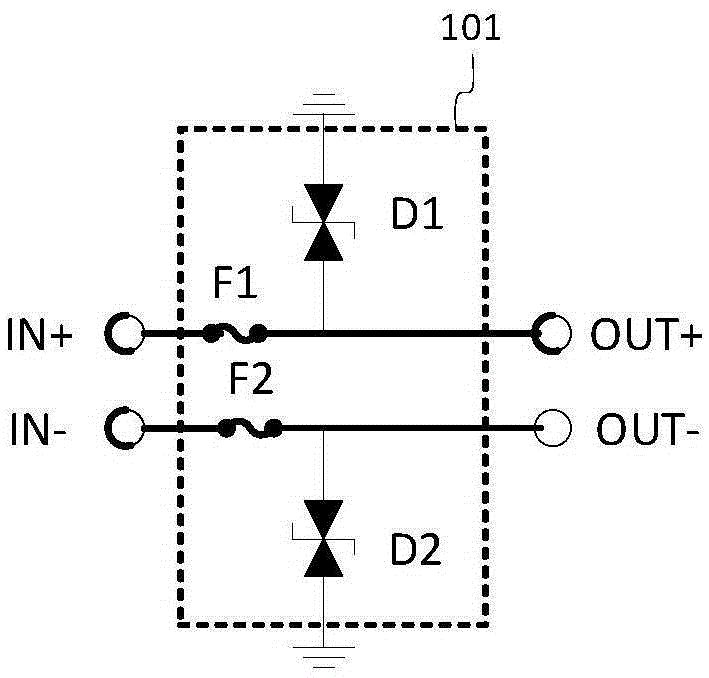

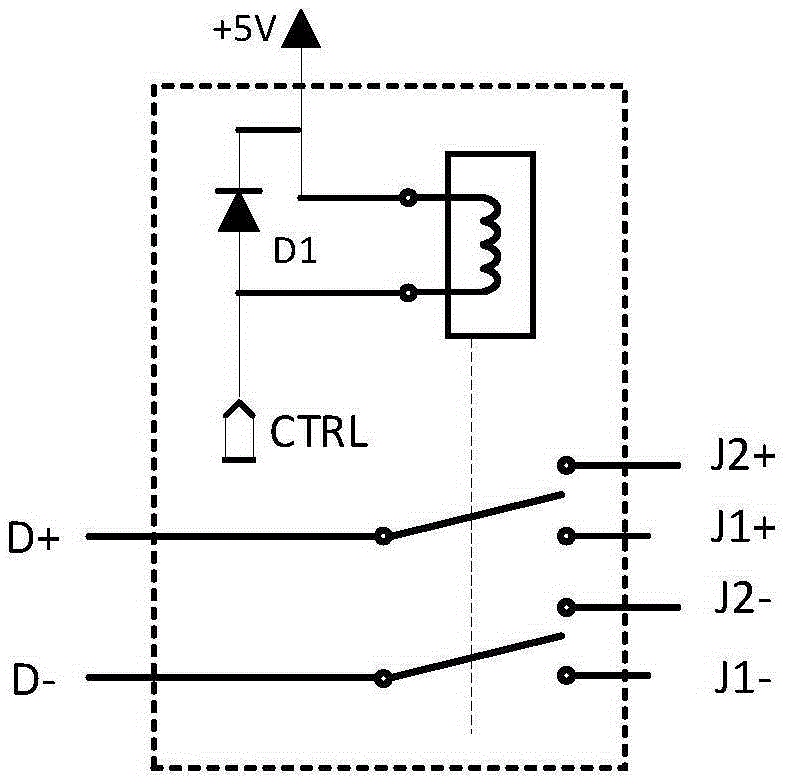

[0049] See figure 1, is a schematic diagram of a signal acquisition circuit for on-line fault diagnosis of magnetic steel provided in this embodiment. As shown in the figure, the signal acquisition circuit 100 includes a signal access module 110, a channel switching module 140, a magnetic steel noise signal Acquisition module 120 and magnetic steel internal resistance signal acquisition module 130, wherein the input of signal access module 110 is connected to both ends of the magnetic steel coil, the output is connected to channel switching module 140, and the corresponding signal acquisition module is connected according to diagnostic requirements , wherein, the signal acquisition module includes a magnetic steel noise signal acquisition module 120 and a magnetic steel internal resistance signal acquisition module 130; input module 110 output to obtain the magnetic steel noise signal, and the magnetic steel noise signal is amplified and then output; the magnetic steel interna...

Embodiment 2

[0062] On the basis of above-mentioned embodiment 1, see Figure 7 The present invention also provides a signal acquisition device suitable for online fault diagnosis of magnetic steel. As shown in the figure, the signal acquisition device 100' includes a signal access module 110, a channel switching module 140, a controller 150, and a magnetic steel noise signal acquisition module 120 and the magnetic steel internal resistance signal acquisition module 130, wherein the input of the signal access module 110 is connected to the coil of the magnetic steel 200, and the output is connected to the channel switching module 140; the channel switching module 140 passes through the signal access module 110 according to the diagnostic requirements. The coil of the magnetic steel 200 is connected to a corresponding signal processing module, which includes a magnetic steel noise signal acquisition module 120 and a magnetic steel internal resistance signal acquisition module 130; the contro...

Embodiment 3

[0071] On the basis of the above-mentioned embodiment 2, the Internet of Things technology can be used to provide a magnetic steel online fault diagnosis system, such as Figure 8 , the system includes a magnetic steel 200, a signal acquisition device 100' and a host computer 300, wherein the signal acquisition device 100' is connected to the magnetic steel, and the magnetic steel is connected to the corresponding signal acquisition channel according to the diagnostic requirements to obtain the magnetic steel noise signal Or the internal resistance signal of the magnetic steel, and output it; the host computer 300 is connected to the signal acquisition device 100', and sends a diagnosis request to the signal acquisition device 100' to receive the magnetic steel noise signal or the magnetic steel internal resistance signal correspondingly, and through judgment Whether it is within the preset reasonable range to determine the fault condition of the magnetic steel to complete the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com