Air exchange system

An air system and air duct technology, applied in the field of air exchange system, can solve the problems of limited effect of improving the air quality of processing environment, limited effect of ventilation, etc., to achieve good treatment effect, reduce equipment utilization, and good air quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

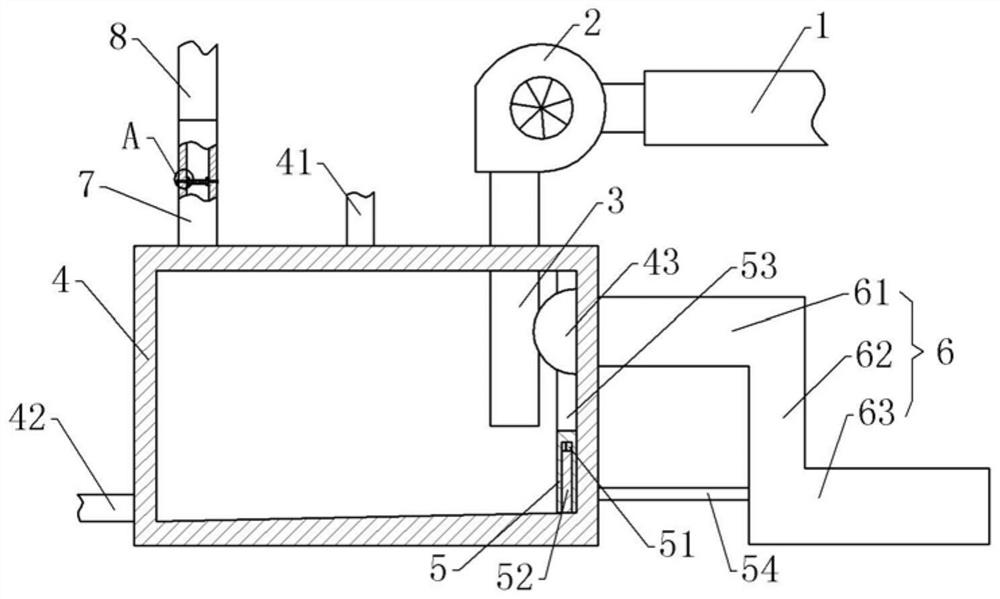

[0037] Air exchange system, basically as attached figure 1 As shown, it includes an air exchange assembly, a cleaning assembly and an air supply assembly. The air exchange assembly includes an air inlet pipe 1, an exhaust fan 2 and an air guide pipe 3. The right end of the air inlet pipe 1 is the air inlet end. During installation, the air inlet placed in the factory building. The air inlet end of the exhaust fan 2 is communicated with the air outlet end of the air inlet pipe 1, the air inlet end of the air guide pipe 3 is communicated with the air outlet end of the exhaust fan 2, and the air guide pipe 3 is vertically arranged.

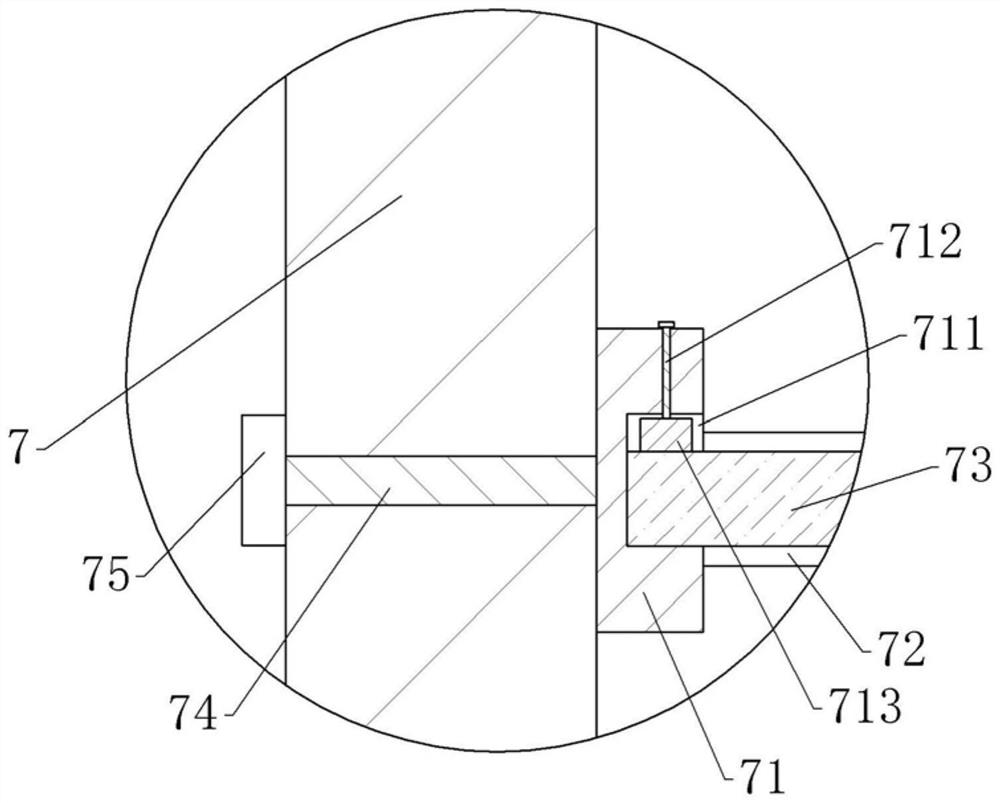

[0038] The air exchange assembly includes a liquid storage tank 4 and a secondary filter pipe 7. The top of the liquid storage tank 4 is provided with a liquid inlet, and the liquid inlet is provided with a liquid inlet valve. The liquid inlet is also connected with a liquid inlet pipe 41, which can be passed through The liquid pipe 41 and the liqui...

Embodiment 2

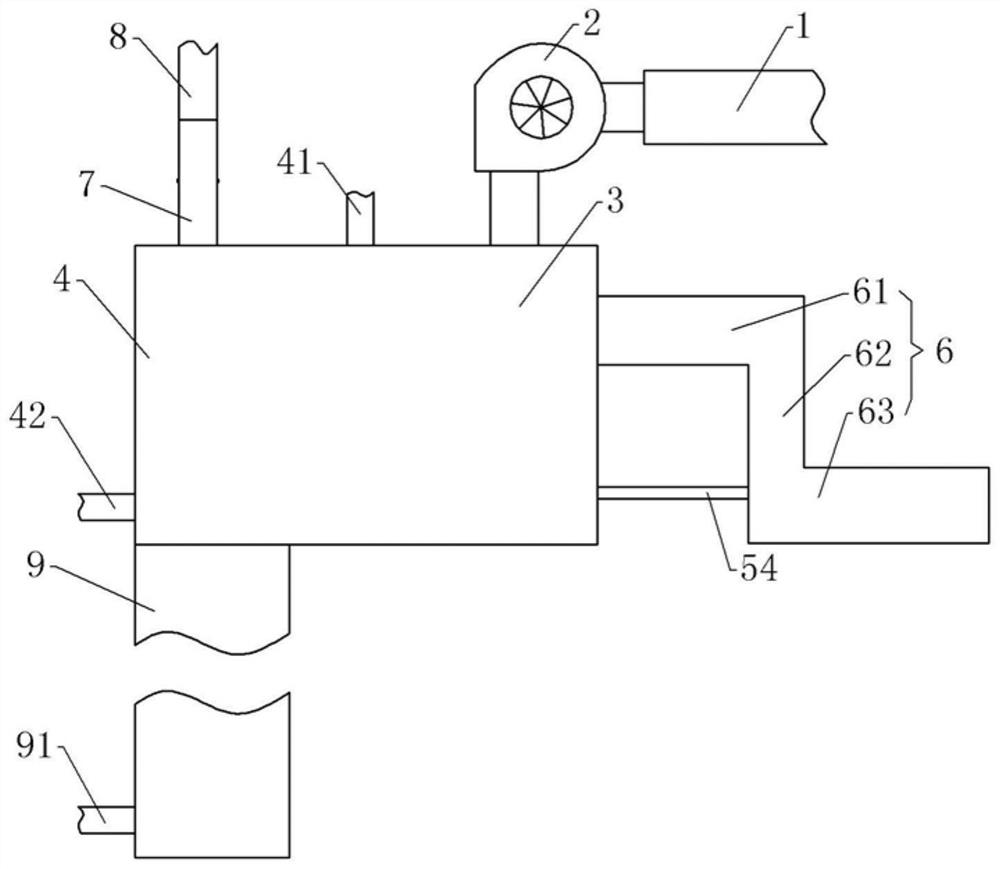

[0053] Embodiment 2 differs from Embodiment 1 only in that, as image 3 As shown, the left side of the bottom of the liquid storage tank 4 is also fixed with a settling tube 9 communicating with the liquid storage tank 4. The height of the settling tube 9 is at least 3 times the height of the liquid storage tank 4. In this embodiment, the height of the settling tube 9 is It is 3 times of the height of the liquid storage tank 4. A cleaning pipe 91 is communicated with the bottom of the left side wall of the settling pipe 9, and an outlet valve is arranged in the cleaning pipe 91.

[0054] The specific implementation process is as follows:

[0055] After the gas is introduced into the liquid storage tank 4, the liquid in the liquid storage tank 4 will flow, which is inconvenient for dust to settle, and by setting the settling tube 9 on the left side, due to the high height of the settling tube 9, the gas enters the liquid storage tank 4. The impact force on the water has less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com