Conveying device for transporting cast tubes

A conveying device and casting pipe technology, applied in the directions of transportation and packaging, conveyors, and strengthening molding, can solve the problems of failing to meet production requirements, affecting the performance and appearance of cast pipes, and labor intensity of workers, and improving production efficiency. , The effect of solving the problem of lifting and transporting the cast pipe, reducing the risk factor and the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0023] In the present invention, unless stated otherwise, the used orientation words such as "up, down, left, right" usually refer to figure 1 Up and down and left and right are shown. "Inner and outer" refer to the inner and outer shown in the specific outline. "Far and near" refer to far and near relative to a certain component.

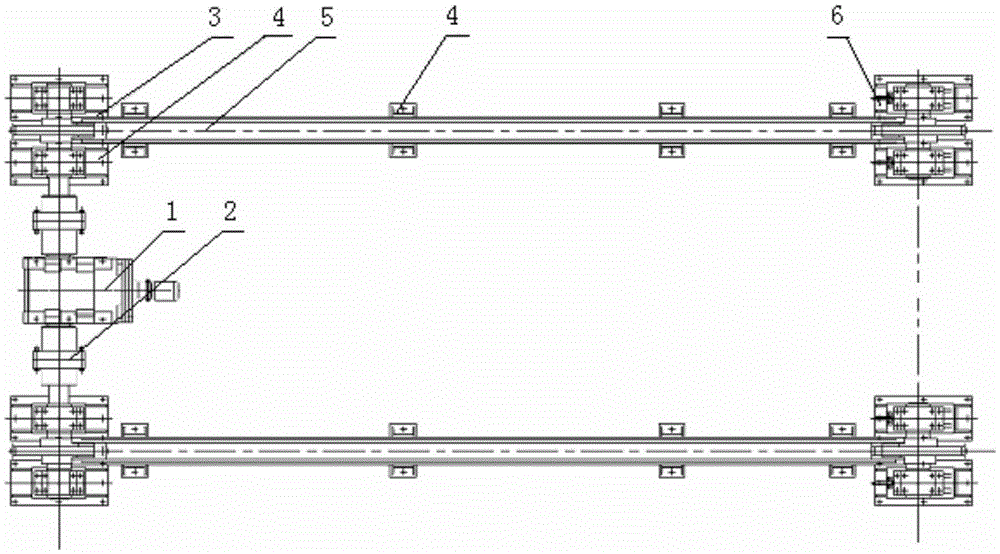

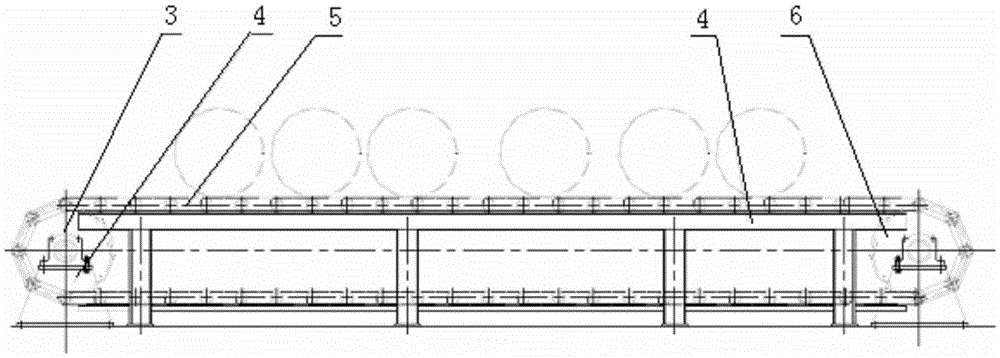

[0024] The present invention provides a conveying device for transporting cast pipes, the conveying device comprises: a driving device, a driving sprocket 3, a driven sprocket 6 and a chain 5, the rotating shaft of the driving device is connected to the driving sprocket 3 , to drive the driving sprocket 3 to rotate; one end of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap