Exhaust valve component and linear compressor

A technology of linear compressors and exhaust valves, which is applied to pump components, mechanical equipment, machines/engines, etc., and can solve problems such as inability to effectively seal cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description and drawings illustrate specific embodiments of the invention sufficiently to enable those skilled in the art to practice them. Portions and features of some embodiments may be included in or substituted for those of other embodiments. The scope of embodiments of the present invention includes the full scope of the claims, and all available equivalents of the claims. These embodiments of the present invention may be referred to herein, individually or collectively, by the term "invention", which is for convenience only and is not intended to automatically limit the application if in fact more than one invention is disclosed The scope is any individual invention or inventive concept.

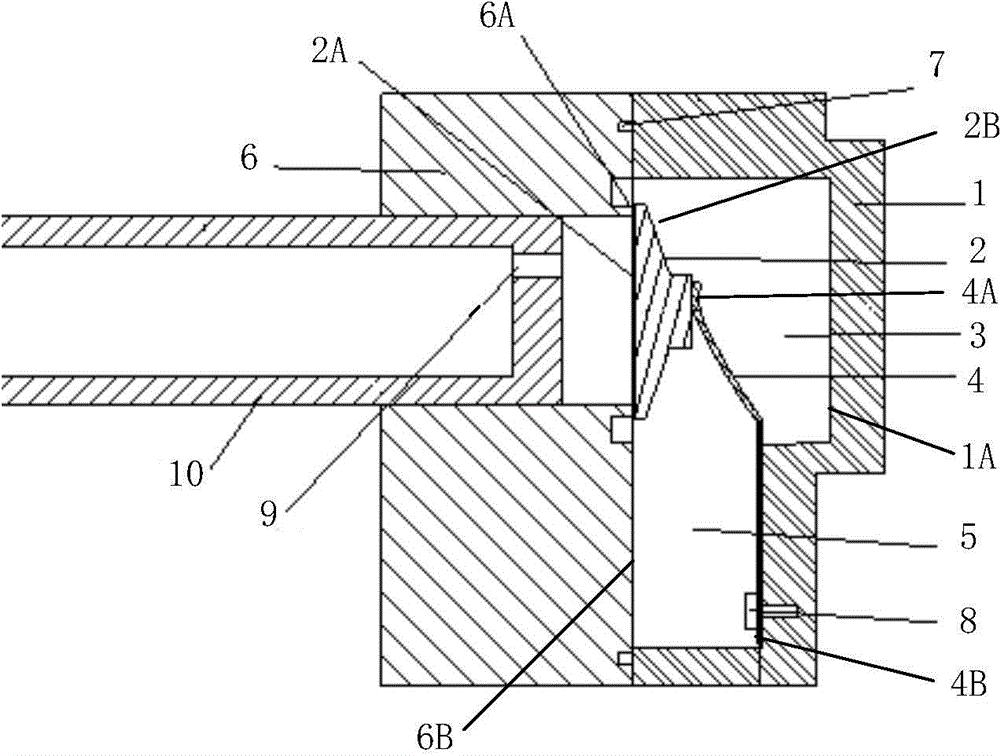

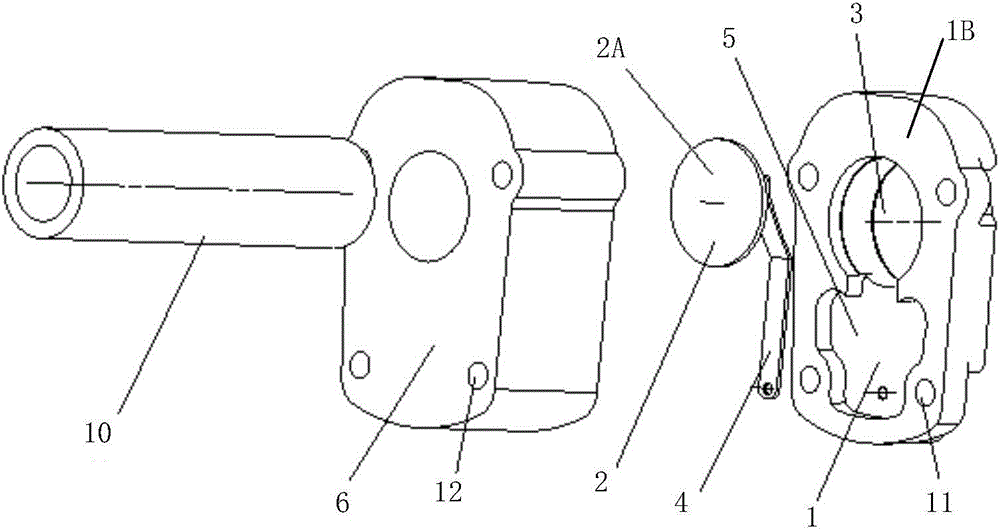

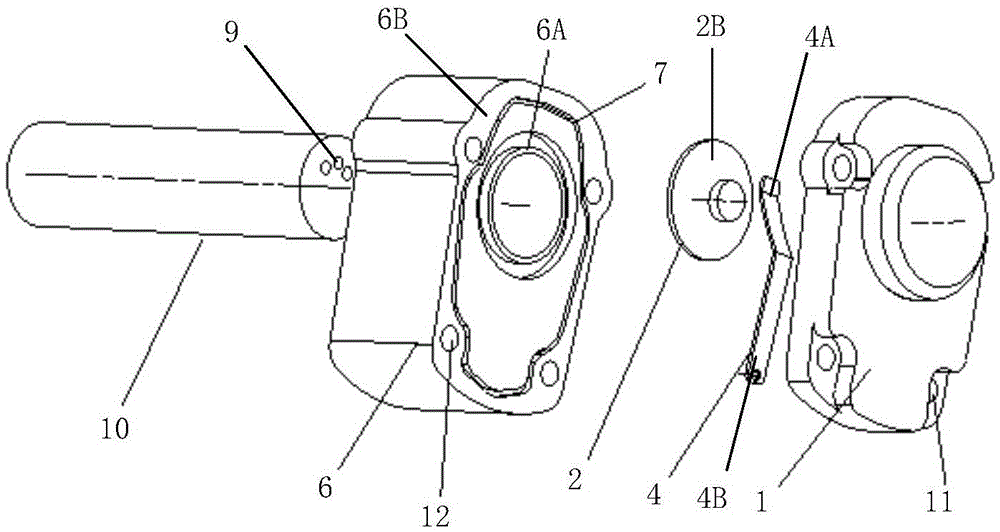

[0020] Refer below Figure 1 ~ Figure 3 A discharge valve assembly and a linear compressor according to an embodiment of the present invention are described in detail.

[0021] Such as figure 1 As shown, an exhaust valve assembly includes: a cylinder head 1 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com