Cultured fish grate connection structure and manufacturing method thereof

A technology for connecting structures and fish steaks, applied in the field of aquaculture, can solve problems such as bolts falling off, cumbersome installation process, edge fractures, etc., and achieve the effects of improving and service life, improving wind and wave resistance, and good wind and wave resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

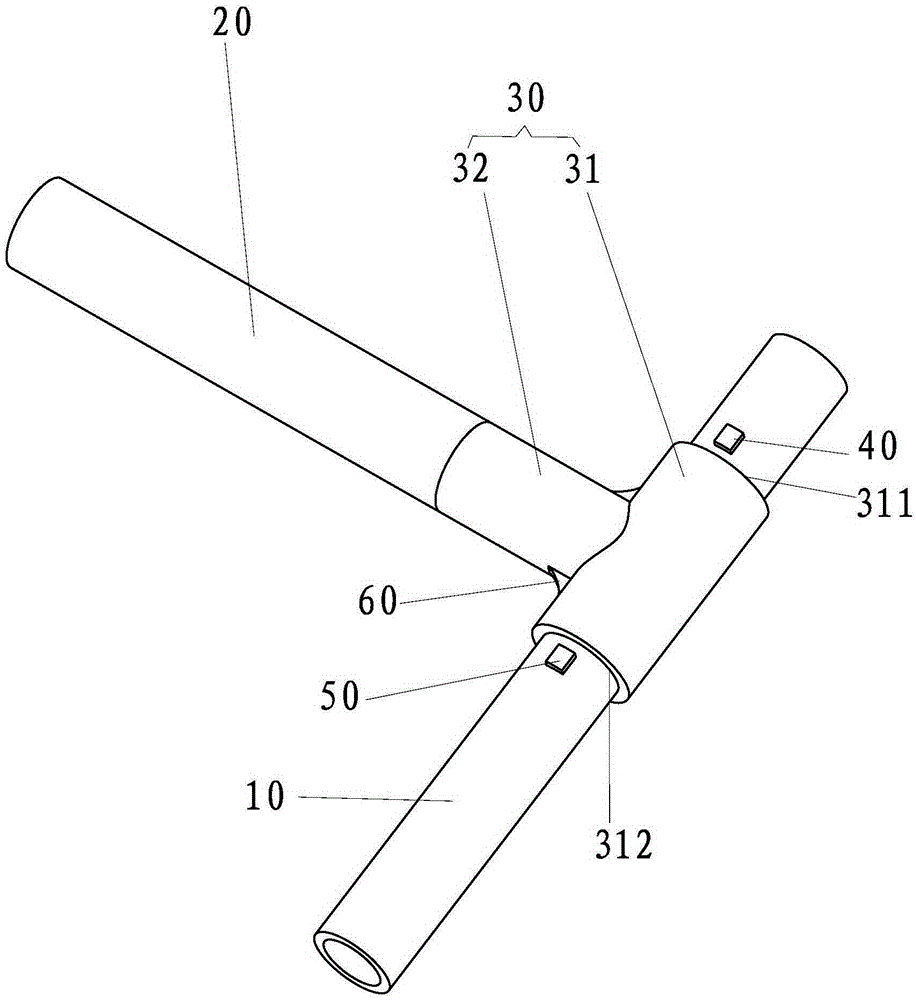

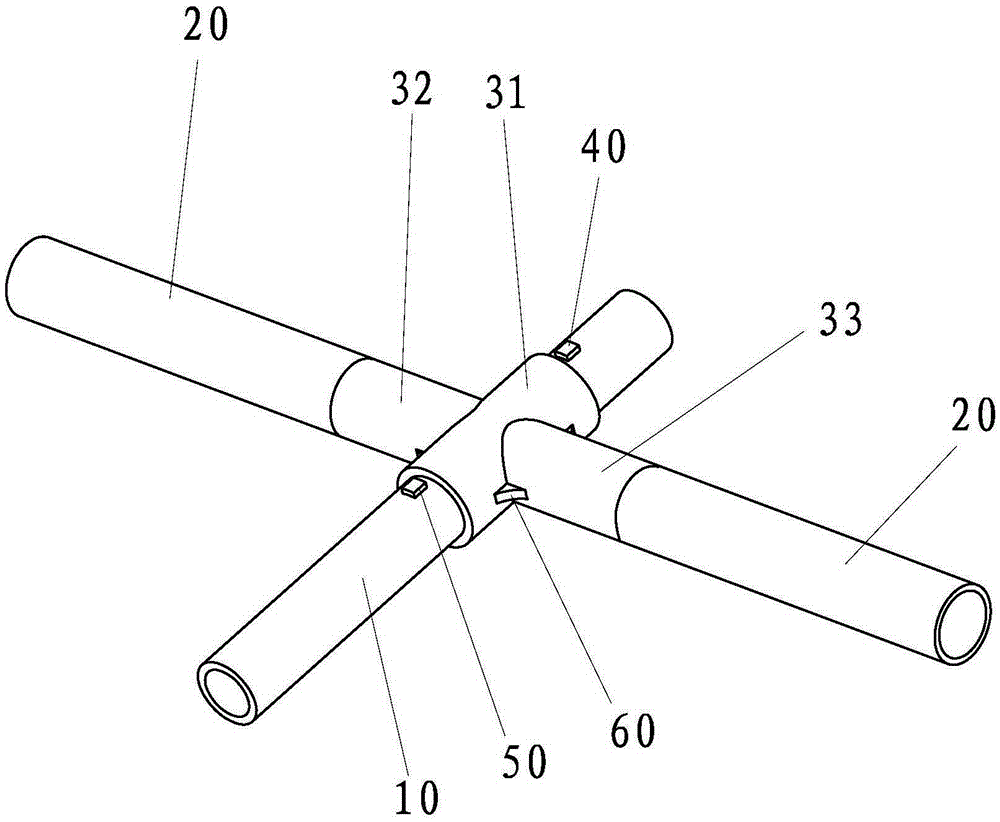

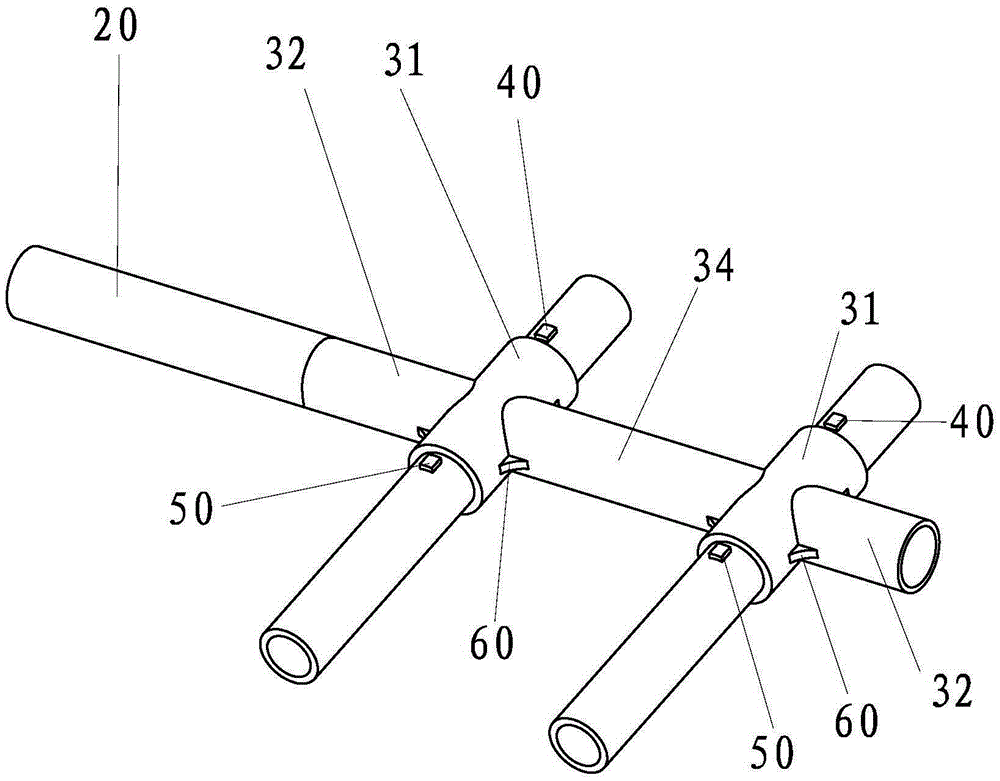

[0037] refer to Figure 1 to Figure 3 , figure 1 It is a structural schematic diagram of the first embodiment of the present invention. The connection structure of the cultured fish raft includes a longitudinal pipe 20, a transverse pipe 10 and a connector 30 for connecting the transverse pipe 10 and the longitudinal pipe 20. The whole cultured fish raft is composed of A plurality of longitudinal pipes 20, transverse pipes 10 and a plurality of connectors 30 are assembled. figure 1Only one unit structure is shown in . In the first embodiment, the connecting piece 30 is a three-way structure. Specifically, the connecting piece 30 includes a first main pipe 31 and a first side pipe 32 connected to each other. The first main pipe 31 and the first side pipe 32 are two The latter is integrally formed by polyviny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com