Cross-flow type cooling tower capable of saving water and eliminating mist

A cross-flow, cooling tower technology, applied in the field of cooling towers, can solve the problem of too many water resources, and achieve the effect of good fog elimination function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

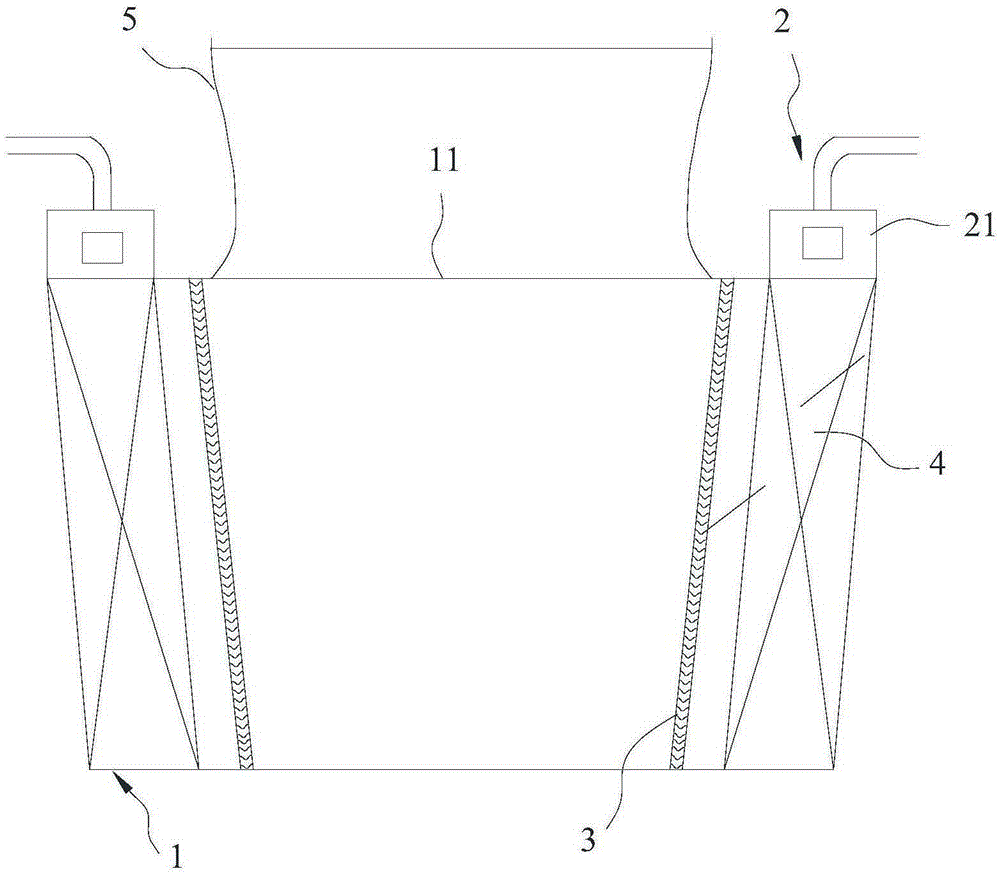

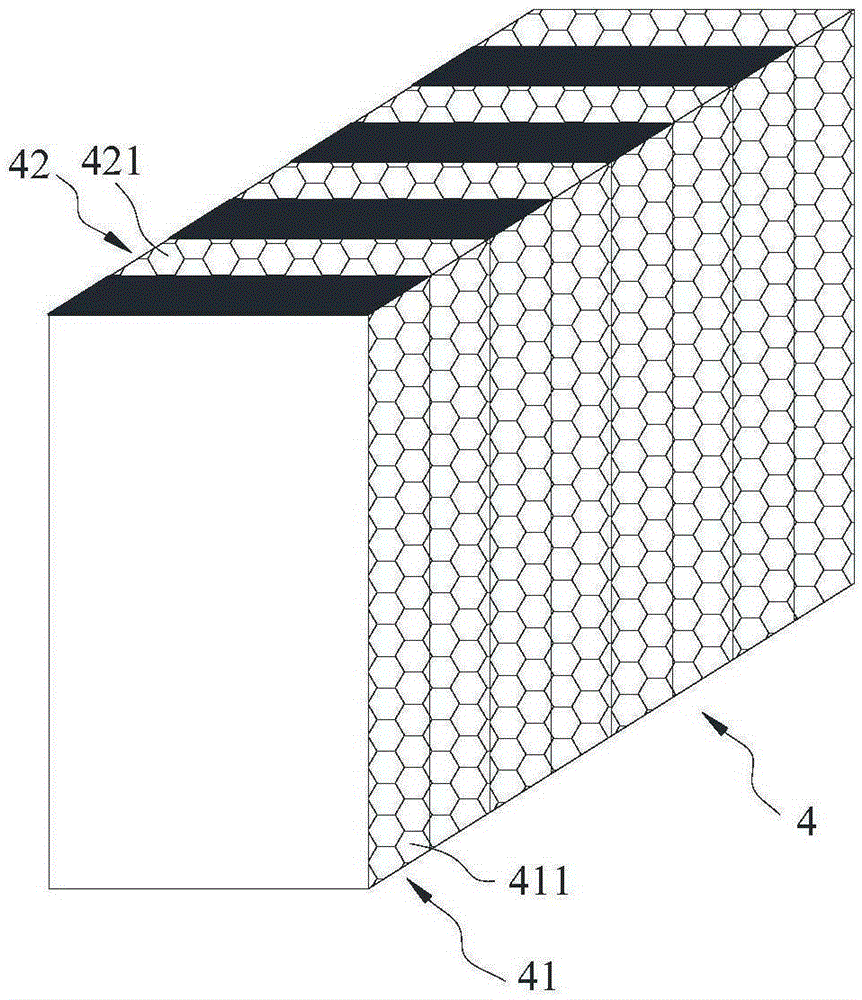

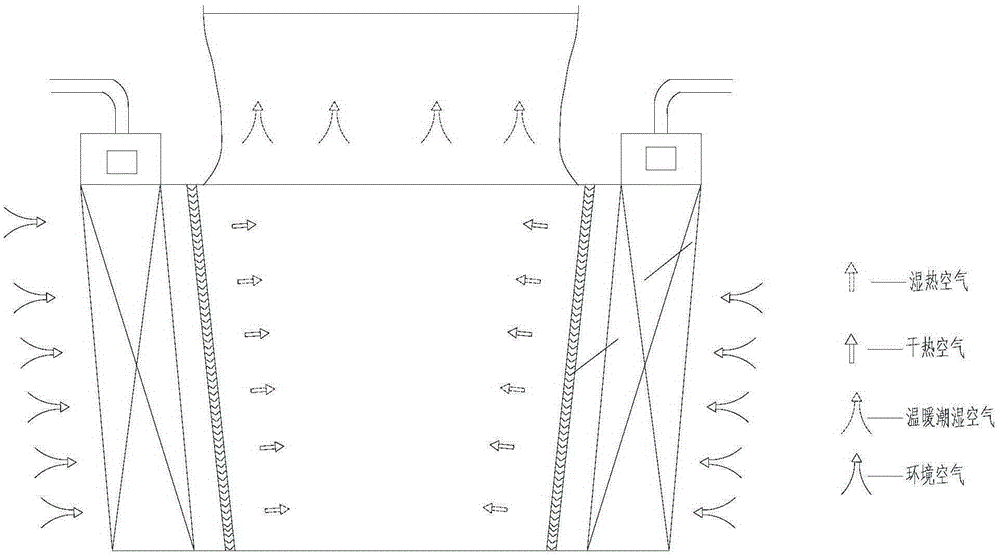

[0020] Such as Figure 1-2 The water-saving and fog-eliminating cross-flow cooling tower shown includes a tower body 1, a water distribution system 2, a water eliminator 3 (also called a water eliminator) for collecting drift droplets entrained in the airflow, and fillers for heat exchange Structure 4, the water distribution system 2 has a water distribution device 21 arranged on the top of the tower body 1, the packing structure 4 is wound around the tower body 1 and forms the peripheral wall of the tower body 1, and the packing structure 4 includes a plurality of first channels for inflowing the cold air flow. A packing body 41 and a plurality of second packing bodies 42 for flowing into the cooling water and cold air flow, the first packing body 41 and the second packing body 42 are arranged in a crosswise direction, and the first packing body 41 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com