Self-cleaning, antifogging and thermal-insulation coating glass and preparation method thereof

A technology of coated glass and composite film layer, which is applied in the direction of coating, etc., can solve the problems of inability to effectively prevent the removal of difficult-to-volatile organic pollutants on the glass surface, the loss of anti-fog effect of the glass, and the influence of film transmittance, etc., to achieve self-cleaning performance Excellent, high hardness, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

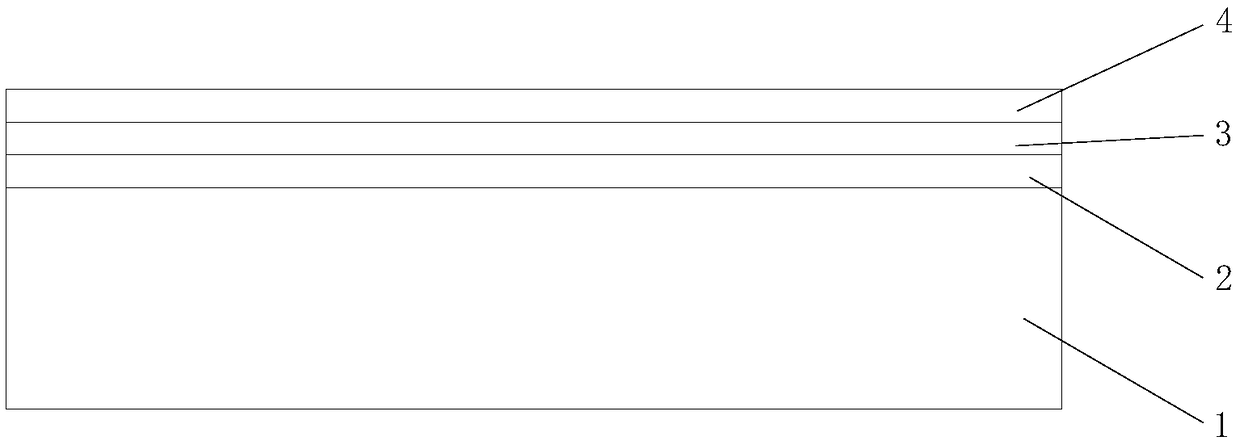

Image

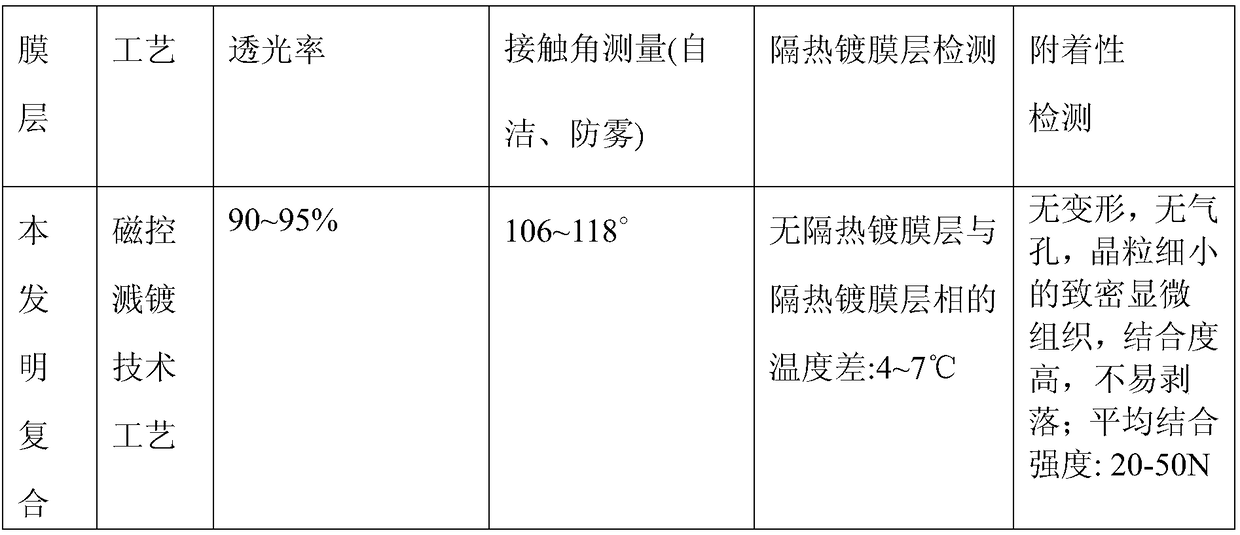

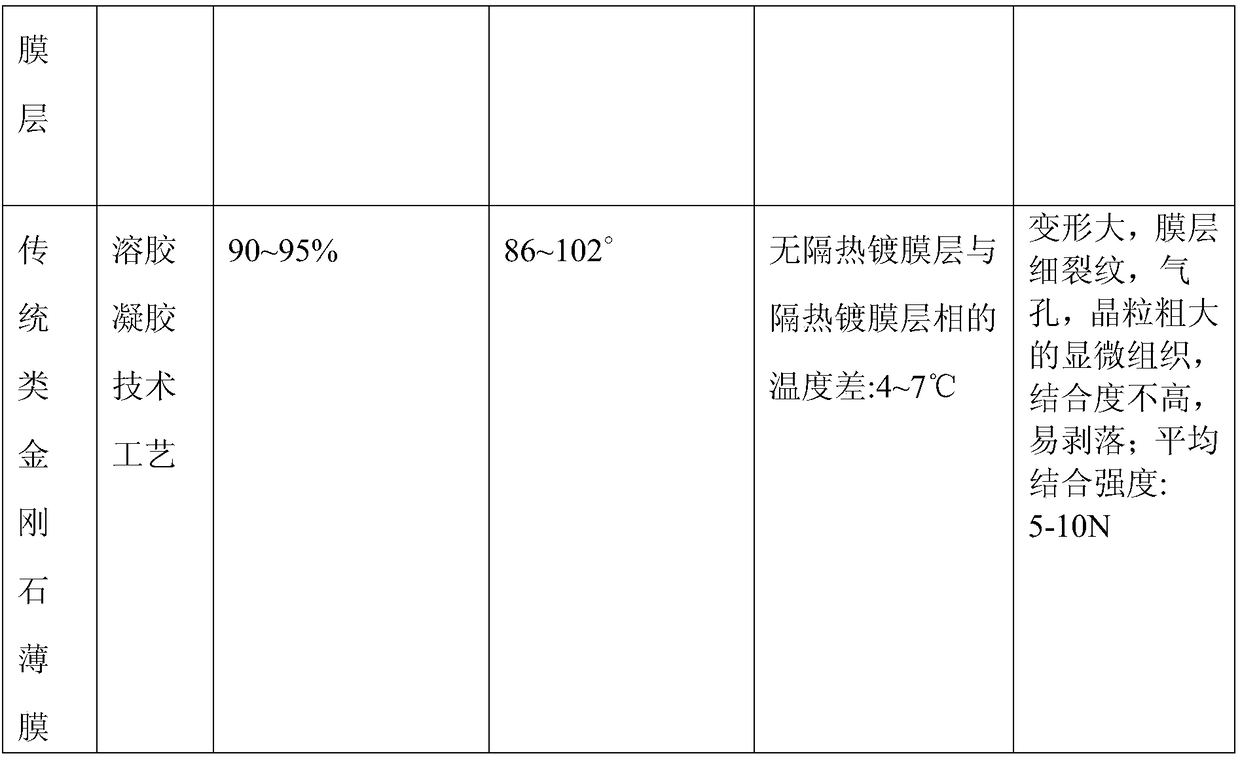

Examples

Embodiment 1

[0023] Embodiment 1, the glass preparation method of the present invention comprises the following steps:

[0024] 1) Clean the substrate with a cleaning machine;

[0025] 2) Inner layer: The substrate is sent to the coating chamber, and the SiO is sputtered by radio frequency magnetron 2 layer, the temperature of the substrate is 25°C, the negative bias voltage is 100V, the working pressure is 0.2Pa, the substrate speed is 2rpm, the silicon dioxide target current is 2A, the argon gas flow rate is 15mL / min, the sputtering time is 10min, the RF power is 100W, and the two The distance between the silicon oxide target and the substrate is 40mm;

[0026] 3) Intermediate layer: continue RF magnetron sputtering of SiO 2 +DLC layer, the temperature of the substrate is 25°C, the negative bias voltage is 100V, the working pressure is 0.2Pa, the substrate speed is 2rpm, the current of the silicon dioxide target is 2A, the current of the carbon target is 2A, the flow rate of argon gas ...

Embodiment 2

[0028] Embodiment 2, the glass preparation method of the present invention comprises the following steps:

[0029] 1) Clean the substrate with a cleaning machine;

[0030] 2) Inner layer: The substrate is sent to the coating chamber, and the SiO is sputtered by radio frequency magnetron 2 layer, the temperature of the substrate is 40°C, the negative bias voltage is 120V, the working pressure is 0.8Pa, the substrate speed is 5rpm, the silicon dioxide target current is 4A, the argon gas flow rate is 20mL / min, the sputtering time is 30min, the radio frequency power is 300W, and the two The distance between the silicon oxide target and the substrate is 50mm;

[0031] 3) Intermediate layer: continue RF magnetron sputtering of SiO 2 +DLC layer, the temperature of the substrate is 40°C, the negative bias voltage is 120V, the working pressure is 0.8Pa, the substrate speed is 5rpm, the current of the silicon dioxide target is 4A, the current of the carbon target is 4A, the flow rate ...

Embodiment 3

[0033] Embodiment 3, the glass preparation method of the present invention comprises the following steps:

[0034] 1) Clean the substrate with a cleaning machine;

[0035] 2) Inner layer: The substrate is sent to the coating chamber, and the SiO is sputtered by radio frequency magnetron 2 layer, the temperature of the substrate is 60°C, the negative bias voltage is 150V, the working pressure is 1Pa, the substrate speed is 8rpm, the silicon dioxide target current is 4A, the argon gas flow rate is 25mL / min, the sputtering time is 50min, the radio frequency power is 300W, the dioxide The distance between the silicon target and the substrate is 60mm;

[0036] 3) Intermediate layer: continue RF magnetron sputtering of SiO 2 +DLC layer, the temperature of the substrate is 60°C, the negative bias voltage is 150V, the working pressure is 1Pa, the substrate speed is 8rpm, the silicon dioxide target current is 4A, the carbon target current is 4A, the argon gas flow rate is 25mL / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com