Method used for rapid evaluation of priming paint performance

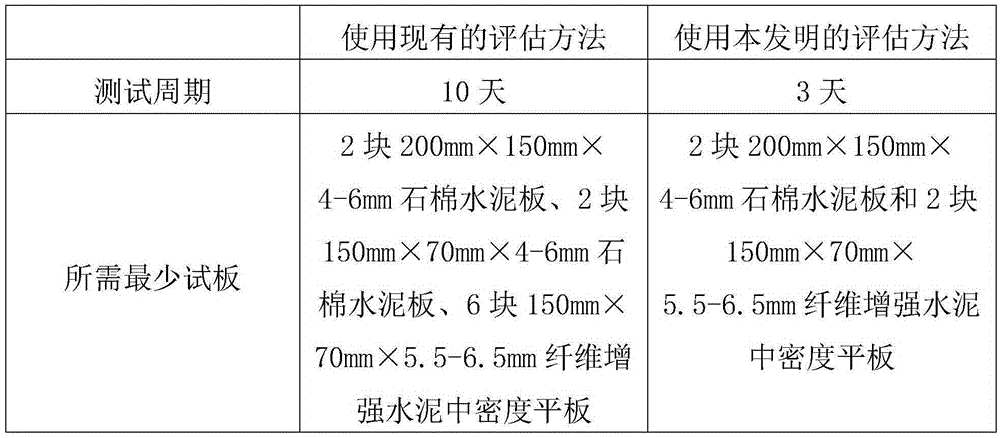

A primer and performance technology, which is applied in the field of rapid evaluation of primer performance, can solve problems such as slowing down the progress of experiments and low efficiency in the development of new primer products, and achieve the effects of reducing workload, increasing the speed of new product development, and saving test consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

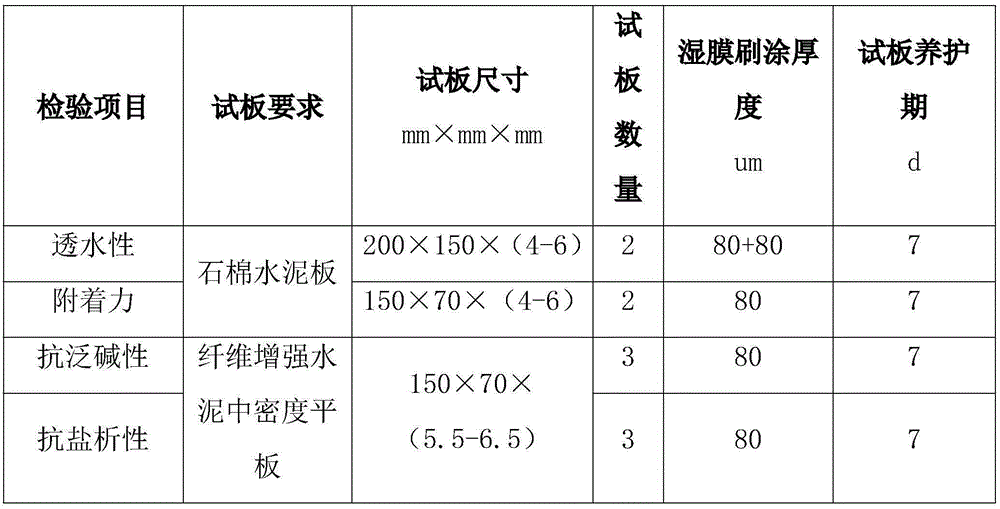

[0033] A method for quickly evaluating primer performance, characterized in that: the method comprises the following steps:

[0034] ① Brush and coat a layer of test primer with a wet film thickness of 70-90um on the surface of two or more asbestos cement boards, place it under constant temperature and humidity conditions for 0.25-0.5h, and then bake it in an oven at 45-55°C for 0.5 -Take it out after 1h, and then place it under constant temperature and humidity conditions for 0.25-0.5h, then paint a layer of test primer with a wet film thickness of 70-90um, and set it aside;

[0035] ②Paint a layer of test primer with a wet film thickness of 70-90um on the surface of more than 2 fiber reinforced cement medium density slabs, and set aside;

[0036] ③ Place the asbestos cement board prepared in step ① and the fiber reinforced cement medium density flat board prepared in step ② for 0.5-1h under constant temperature and humidity conditions, put them in an oven at 50-60°C for 15-2...

Embodiment 1

[0052] A method for quickly evaluating primer performance, characterized in that: the method comprises the following steps:

[0053] ① Brush a layer of test primer with a wet film thickness of 80um on the surface of two asbestos cement boards, place it under constant temperature and humidity conditions for 0.5h, then bake it in a 50°C oven for 1h, take it out, and then put it in a constant temperature and constant After placing it under wet conditions for 0.5h, paint a layer of test primer with a wet film thickness of 80um respectively, and set aside;

[0054] ② Brush a layer of test primer with a wet film thickness of 80um on the surface of the 3 fiber reinforced cement medium density flat panels, and set aside;

[0055] ③ Place the asbestos cement board prepared in step ① and the fiber reinforced cement medium density flat board prepared in step ② for 0.5h under constant temperature and humidity conditions, put them in an oven at 50°C for 18 hours, take them out, and then pl...

Embodiment 2

[0070] A method for quickly evaluating primer performance, characterized in that: the method comprises the following steps:

[0071] ① Brush a layer of test primer with a wet film thickness of 70um on the surface of the two asbestos cement boards, place it under constant temperature and humidity conditions for 0.25h, then bake it in a 45°C oven for 0.5h, take it out, and then place it at a constant temperature After placing it under constant humidity conditions for 0.3h, paint a layer of test primer with a wet film thickness of 90um respectively, and set aside;

[0072] ② Brush a layer of test primer with a wet film thickness of 70um on the surface of the two fiber reinforced cement medium density slabs, and set aside;

[0073] ③Place the asbestos cement board prepared in step ① and the fiber reinforced cement medium density flat board prepared in step ② under constant temperature and humidity conditions for 1 hour, put them in an oven at 55°C for 15 hours, take them out, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com