A low-loss large effective area single-mode optical fiber and its optical fiber preform manufacturing method

An effective area, single-mode optical fiber technology, applied in the direction of cladding optical fiber, manufacturing tools, optical waveguide light guide, etc., can solve the problem of increasing process complexity and manufacturing cost, unstable fiber loss and cut-off wavelength, and reducing product quality stability, etc. problem, to achieve the effects of low loss, low macrobending loss, and low fiber loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

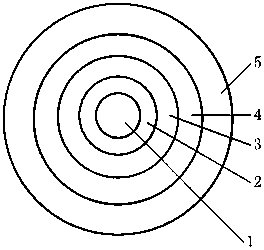

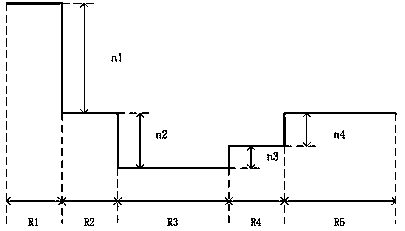

[0030] Refer to attached Figure 1~3 , a single-mode optical fiber with low loss and large effective area, its effective area at 1550nm is 100-200μm 2 , the cut-off wavelength of the optical cable is less than 1500nm, and the optical fiber includes the core area 1, the isolation area 2, the ditch area 3, the protection area 4 and the outer cladding area 5 from the center to the periphery in sequence, where:

[0031] a) Core region 1: a radius R1 extending outward from the center, the range of R1 is 4-10 μm, and its typical value is 6.0-9.0 μm. The range of refractive index difference in this area is 0-0.3%, and the typical value is 0.1%-0.2%.

[0032] b) Isolation region 2: extending outward from R1, the thickness is R2, the range of R2 is 2-21 μm, and its typical value is 5-10 μm. The range of refractive index difference in this area is -0.005% to 0.05%, and the typical value is 0 to 0.005%.

[0033]c) Trench region 3: extending outward from R1+R2, the thickness is R3, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| dispersion value | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com