Self-inspection circuit for brushless DC motor of anesthesia machine

A brushless DC motor and self-checking circuit technology, applied in the field of anesthesia machines, can solve problems such as motor failure, inability to accurately adjust the speed of the brushless DC motor, and achieve the effect of accurately adjusting the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

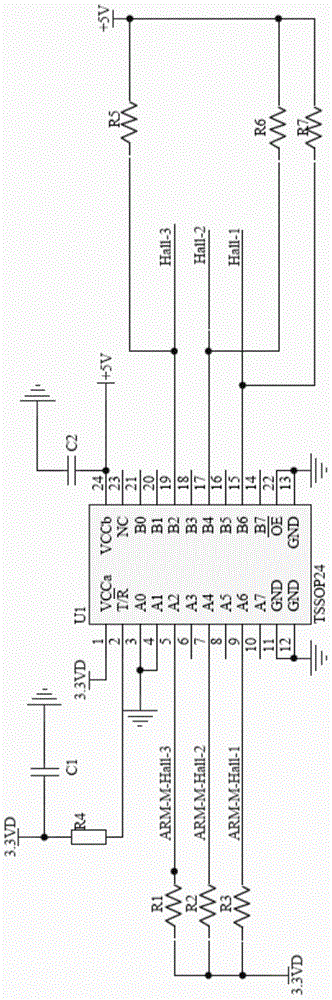

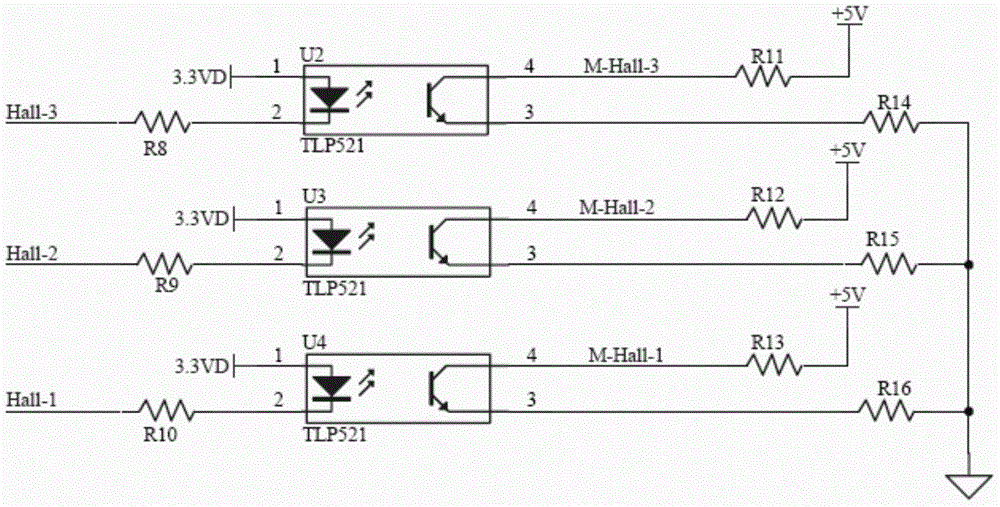

[0020] Combine below Figure 1-Figure 4The technical solutions of the present invention are further described through specific implementation methods.

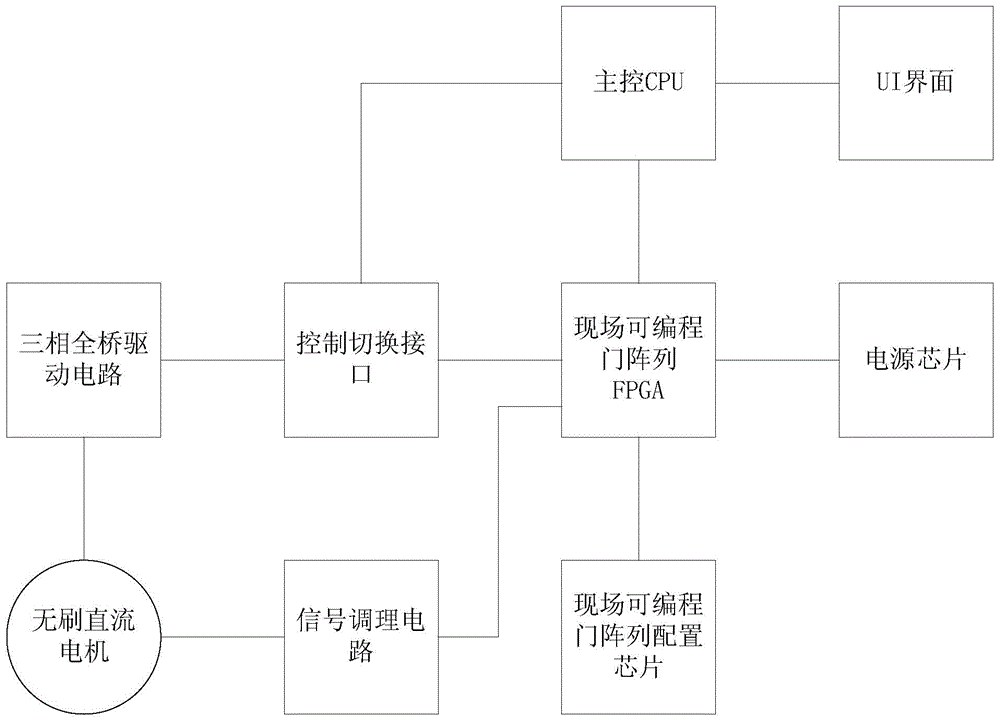

[0021] figure 1 It is a functional structural diagram of a brushless DC motor self-inspection circuit of an anesthesia machine provided by a specific embodiment of the present invention.

[0022] A brushless DC motor self-checking circuit of an anesthesia machine, comprising: a main control CPU, a field programmable gate array, a three-phase full-bridge drive circuit and a signal conditioning circuit, the main control CPU is connected with the field programmable gate array, and the The above-mentioned three-phase full-bridge driving circuit is respectively connected with the main control CPU and the field programmable gate array. When the brushless DC motor self-checks, the main control CPU simulates the driving signals of the three-phase full-bridge driving circuit under various speed conditions. The ability of the field pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com