High-pressure pump and fuel injection system having a high-pressure pump

A fuel injection and high-pressure pump technology, which is applied to fuel injection pumps, fuel injection devices, fuel injection control, etc., can solve problems such as pressure fluctuation loads and pressure fluctuations increase, interfere with synchronous injection strokes, and reduce the load. , the effect of improving the injection performance, improving the working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

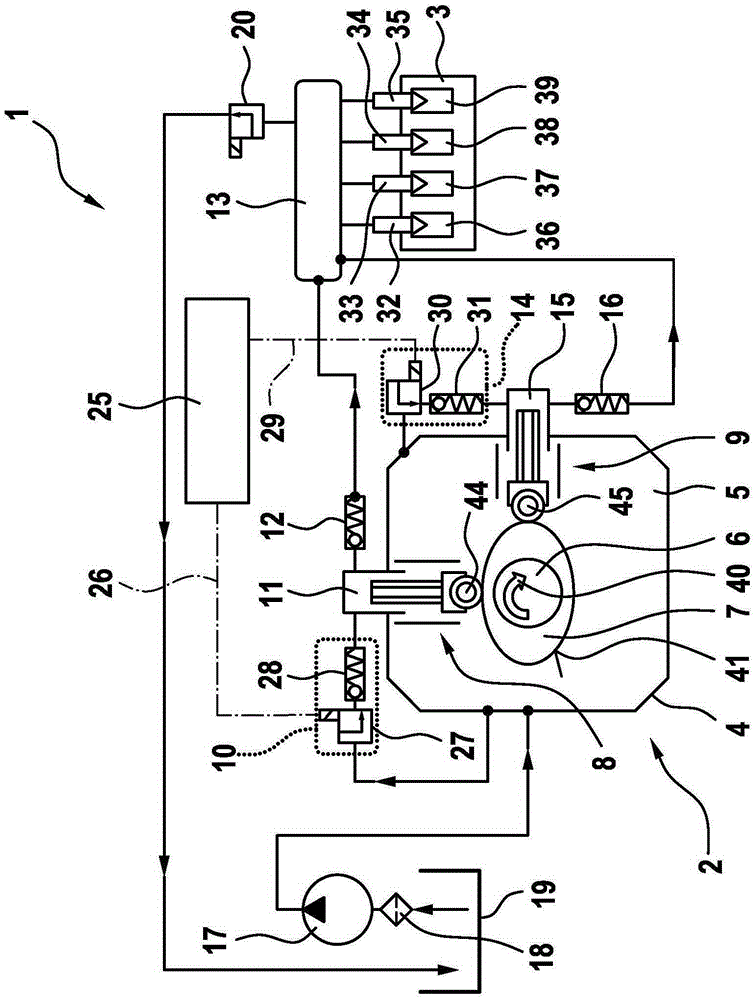

[0019] figure 1 According to an exemplary embodiment, a structural arrangement 1 with a high-pressure pump 2 and an internal combustion engine 3 are shown in a schematic diagram. In particular, the high-pressure pump 2 can be designed as a radial piston pump or as an in-line piston pump. The structural arrangement 1 can be designed in particular as a fuel injection system 1 and be used for a supercharged, self-igniting internal combustion engine 3 .

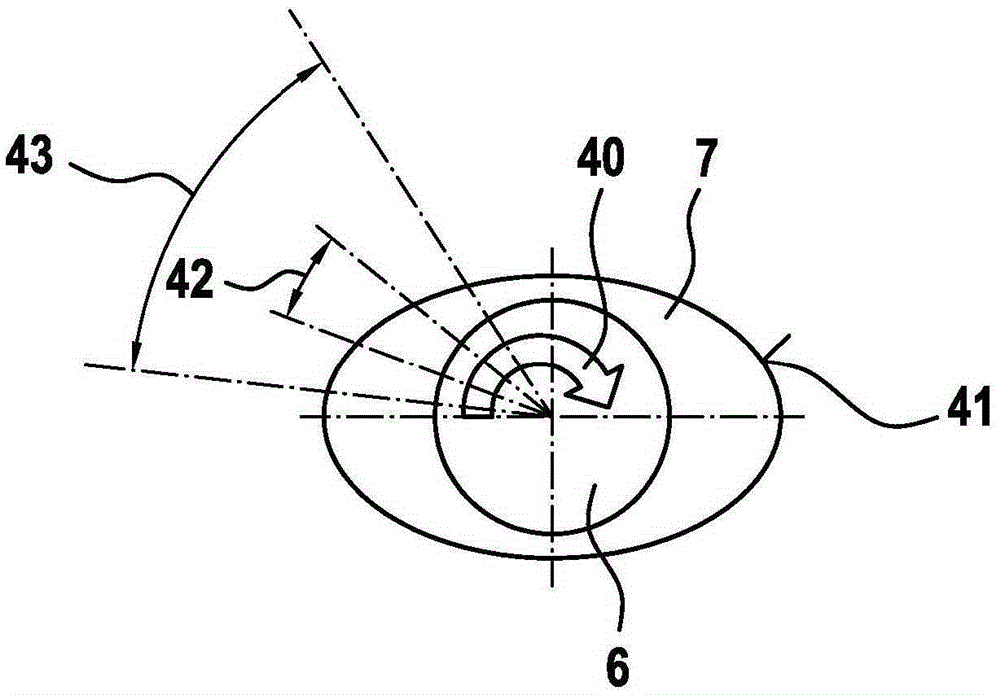

[0020] The high-pressure pump 2 has a pump housing 4 in which a drive mechanism chamber 5 is formed. A drive shaft 6 with a cam 7 is mounted in this pump housing 4 . The cam 7 is designed as a double cam 7 in this exemplary embodiment. In this case, the cam 7 can be configured as a multiple cam according to the corresponding variant. Furthermore, the term “cam” also includes a configuration of the cam 7 in which the drive shaft 6 has an eccentric section or the like.

[0021] The high-pressure pump 2 has a first pump unit 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com