Noodle resting device

A technology for curing and noodle, which is applied in the direction of dough processing, dough fermenter, baking, etc. It can solve the problems of not being as good as handmade noodles, bad taste of noodles, and shortening the aging time of flour, so as to prevent pollution, prolong the aging time, and have a better taste The effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

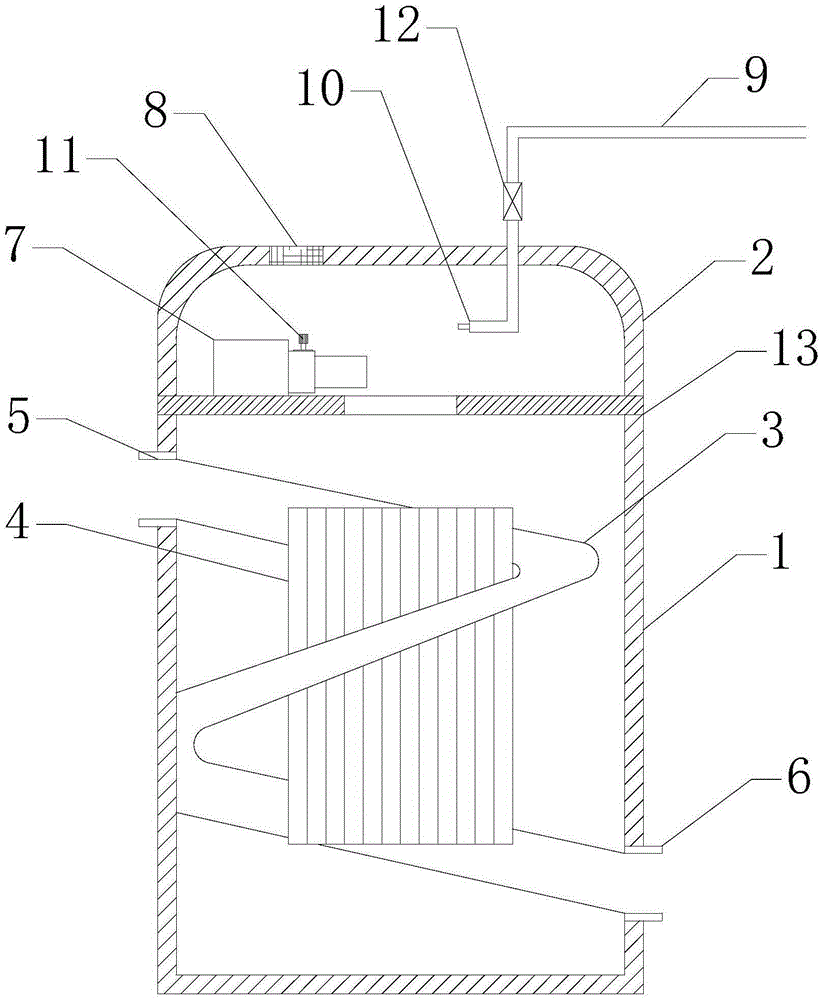

[0022] like figure 1 As shown, a noodle curing device includes a casing 1, a machine cover 2, a fabric track 3, and a heating device 4, the top of the casing 1 is provided with a partition 13, and the cover 2 is installed on the partition 13;

[0023] Described casing 1 is provided with feed inlet 5, discharge outlet 6, and casing 1 interior is provided with fabric rail 3, and one end of fabric rail 3 links to each other with feed inlet 5, and the other end corresponding to fabric rail 3 is connected with discharge. The port 6 is connected, the inside of the casing 1 is provided with a heating device 4, and the fabric track 3 is spirally wrapped around the outside of the heating device 4;

[0024] The dividing plate 13 is provided with an automatic powder spreader 7, and the middle position of the dividing plate 13 is provided with a through hole, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com