Machining device for U-shaped metal part

A technology for processing equipment and metal parts, applied in the field of U-shaped metal parts processing equipment, can solve the problems of reducing the processing efficiency of U-shaped metal parts and increasing the processing time of U-shaped metal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

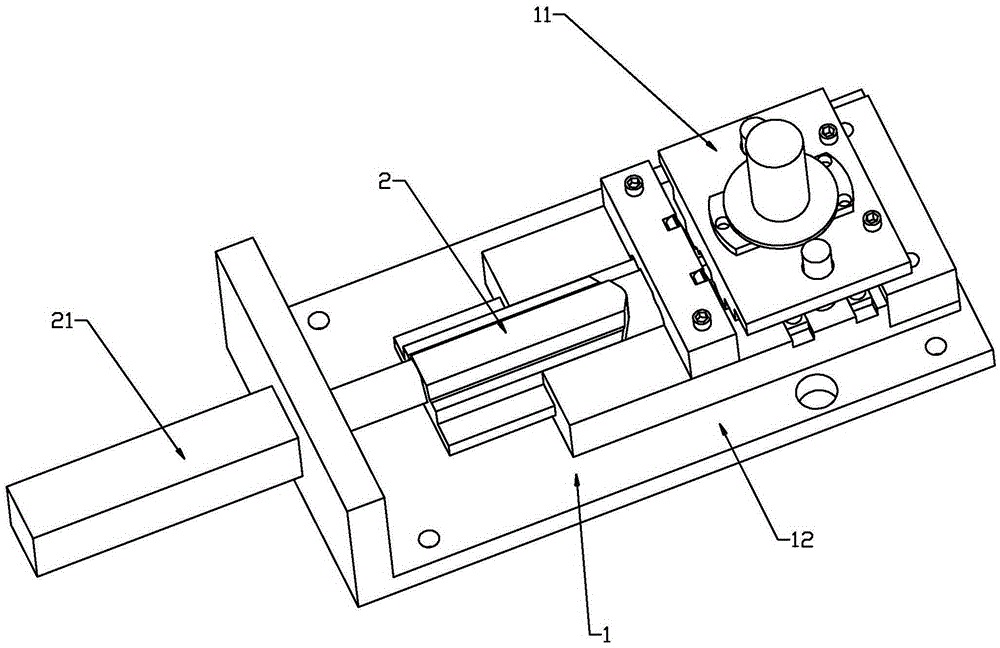

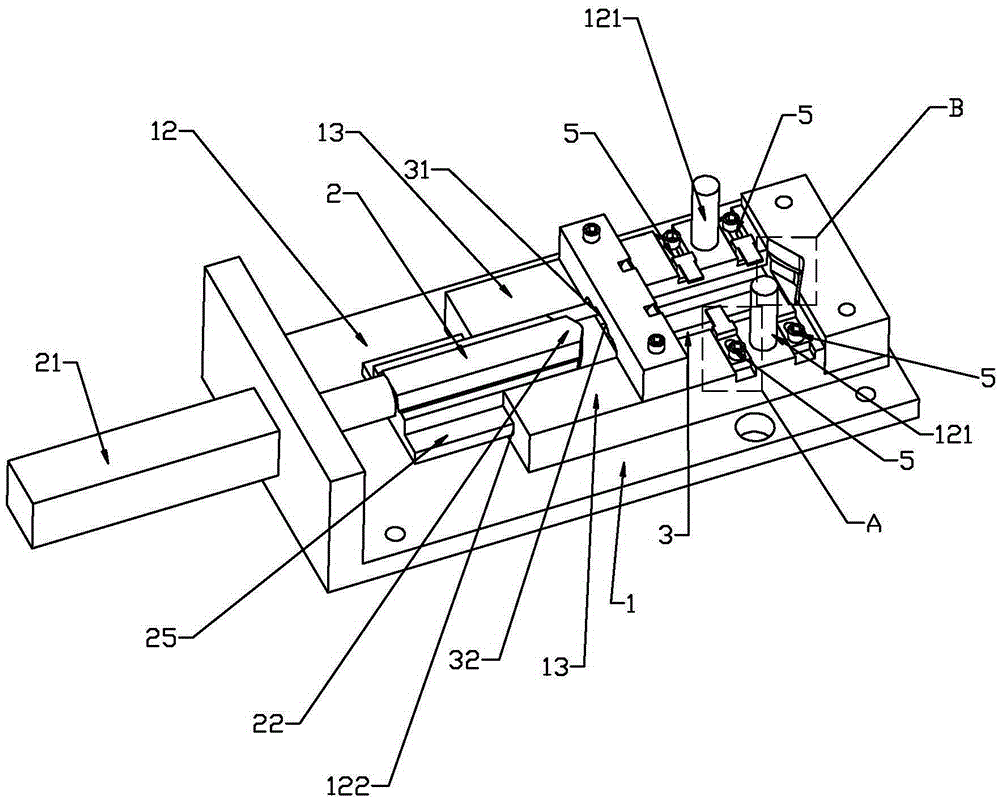

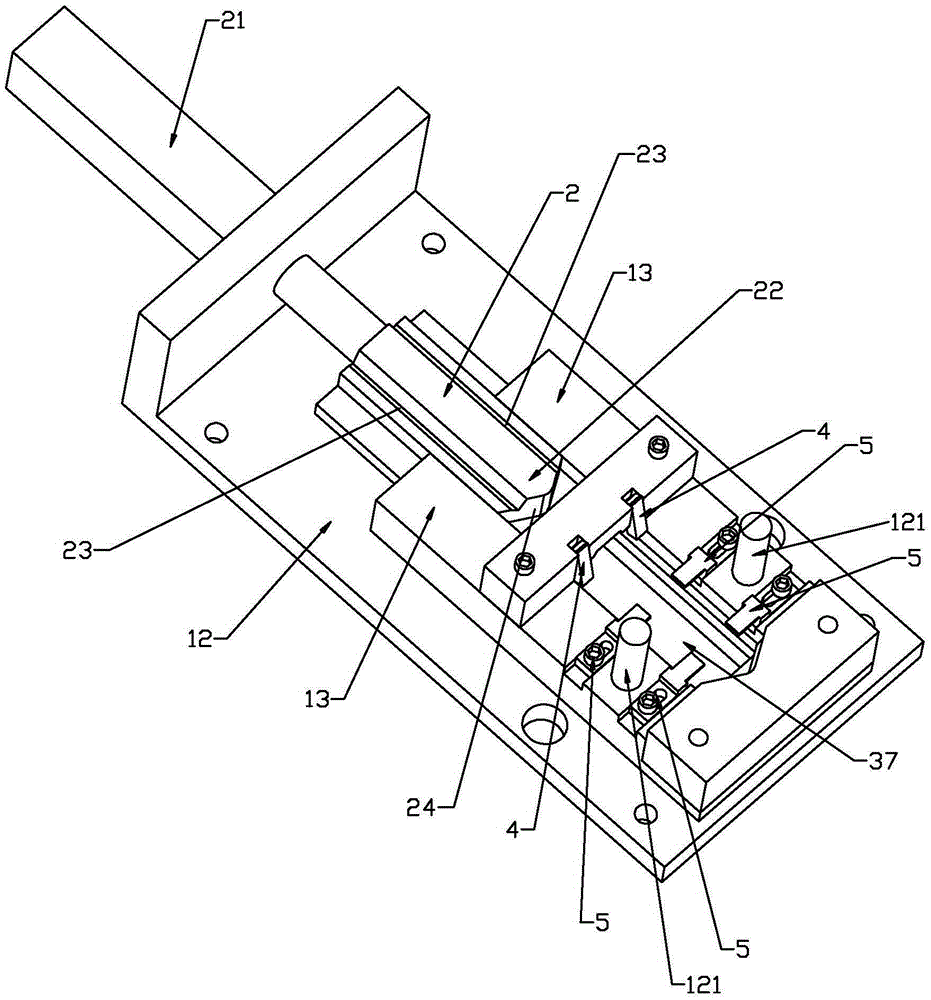

[0025] Such as figure 1 — Figure 8 As shown, the present invention discloses a U-shaped metal part processing equipment, including a processing seat 1 and a pushing block 2. The processing seat 1 is provided with a processing cavity 3, and the processing cavity 3 is opposite to the pushing block 2 with an inlet and outlet 31. The block 2 is provided with a driving mechanism 21 to linearly push the pushing block 2 into the processing cavity 3. The end of the pushing block 2 facing the entrance serves as the pushing end 22 for pushing the linear metal part into the processing cavity 3. The processing seat 1 is located in the pushing block 2 Both sides are provided with a linear metal part placement platform 13, and the processing cavity 3 is provided with a preliminary processing part, a side shaping part and a bending and shaping part in sequence along the moving track of the pushing block 2. The preliminary processing part includes a moving track along the pushing block 2 A ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com