A welding robot welding wire feeding conduit device

A welding robot and wire guide technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of burnout of welding torch, unreasonable installation structure of welding wire guide and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

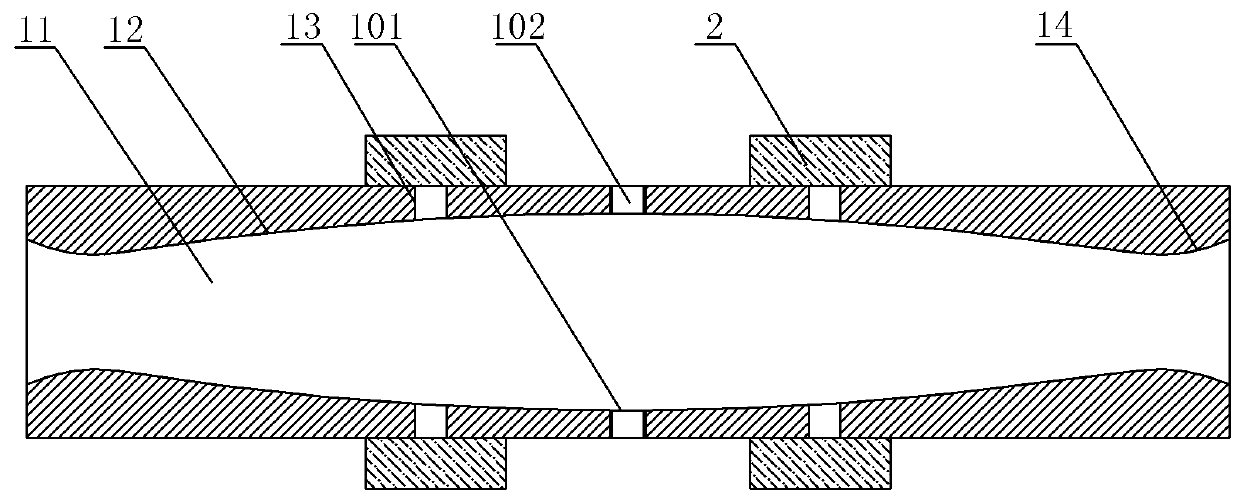

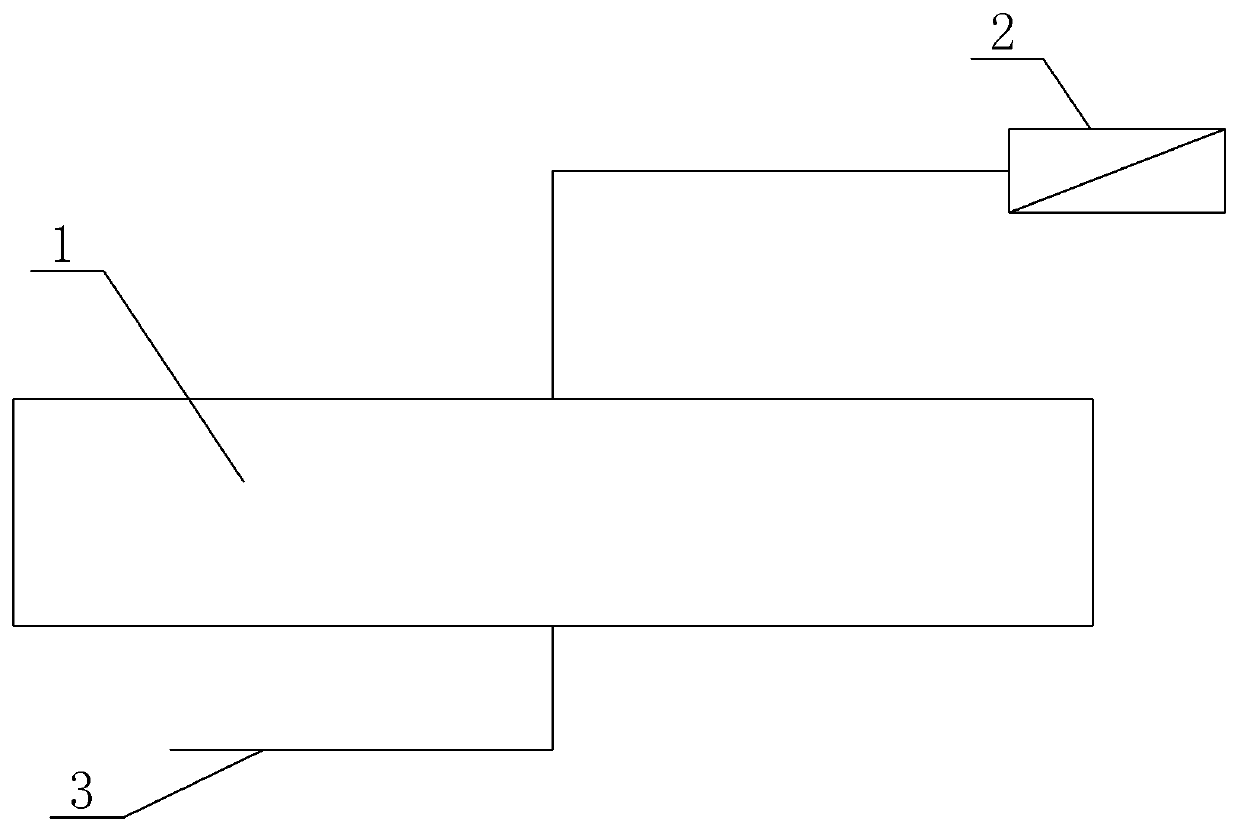

[0012] The reference signs in the drawings of the description include: conduit 1, vacuum cleaner 2, compressed air intake pipe 3, inner hole 11, concave arc 12, through hole 13, bell mouth 14, first threaded hole 101, second threaded hole 102 .

[0013] The embodiment is basically as figure 1 Shown: a welding robot welding wire feeding catheter device, including a catheter 1 made of hard plastic ceramics, the catheter 1 is provided with an inner hole 11 for the welding wire to pass through, and the side wall of the inner hole 11 is in a concave arc shape 12. A first threaded connection hole and a second threaded connection hole are respectively opened in the recesses of the concave arc 12 . Such as figure 2 As shown, the vacuum cleaner 2 communicates with the inner hole 11 through the first threaded hole 101 , and the compressed air inlet pipe 3 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com