Tool for running-in machining of ball body and valve seat of ball valve

A ball and tooling technology, applied in the field of grinding and processing, can solve problems such as the limitation of the grinding surface, the influence of the sealing performance of the ball and the valve seat, and the inability to realize matching research, etc., and achieve the effect of fast processing efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

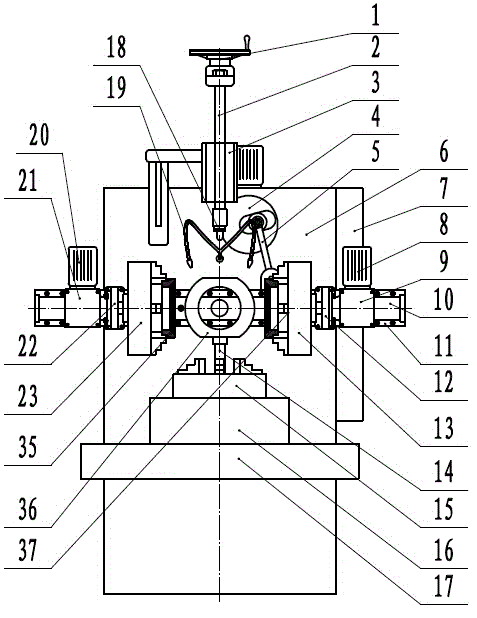

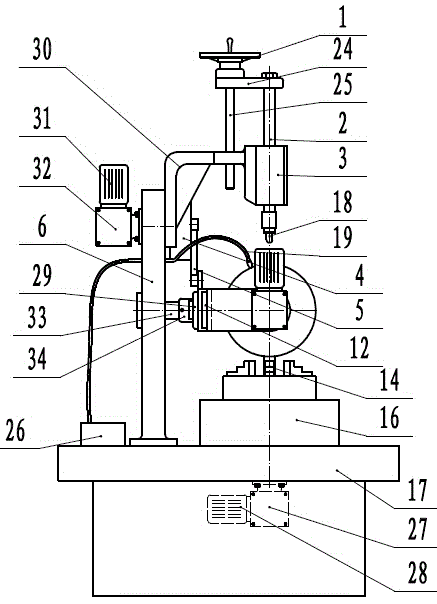

[0016] Such as figure 1 As shown, a kind of tooling for the ball and valve seat of a ball valve to be matched and processed, including the tooling body, the tooling body includes a base 17, a bracket 6 and a numerical control operation panel 7, a sphere spindle system is installed on the base 17, and a sphere top is installed on the bracket 6 installation device, abrasive conveying system and guide rail mounting mechanism, a left grinding head spindle system and a right grinding head spindle system are installed symmetrically on the guide rail mounting mechanism with the center line of the base 17 as the center, and a beam swing is installed on the bracket 6 Mechanism, beam swing mechanism includes crank wheel 4, rocker 5, servo motor A31 and reduction box A32, servo motor A31 is connected with reduction box A32, reduction box A32 is fixedly installed on the back of bracket 6, and the output shaft of reduction box A32 passes through The bracket 6 is fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com