Buffer combining polymeric elastic components and metal friction components

A technology of elastic elements and friction elements, which is applied in the field of coupler buffers for locomotives and vehicles, can solve the problems that cannot meet the requirements of high energy absorption rate of the buffer, and achieve the effect of simple structure, high reliability and improved absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

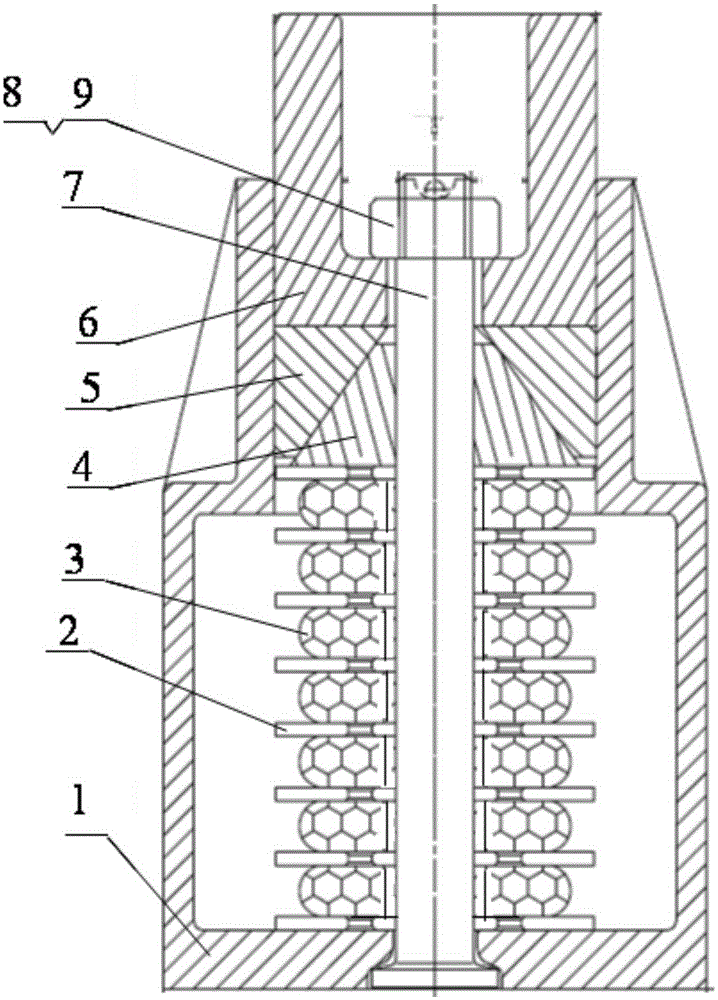

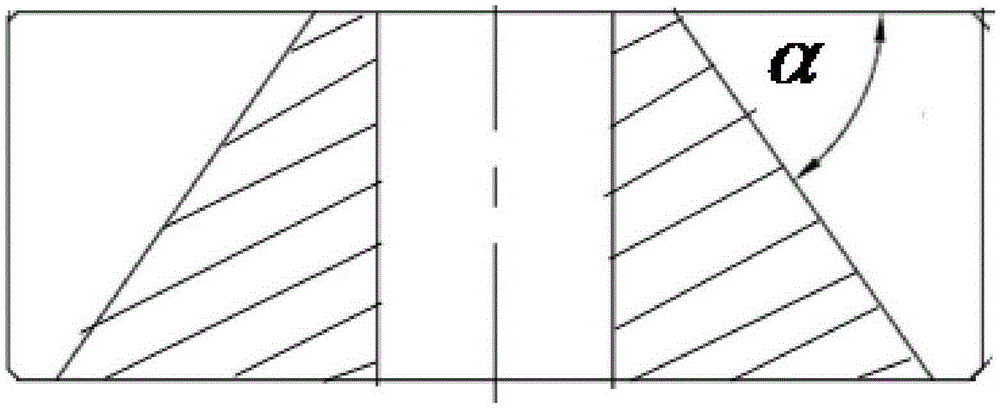

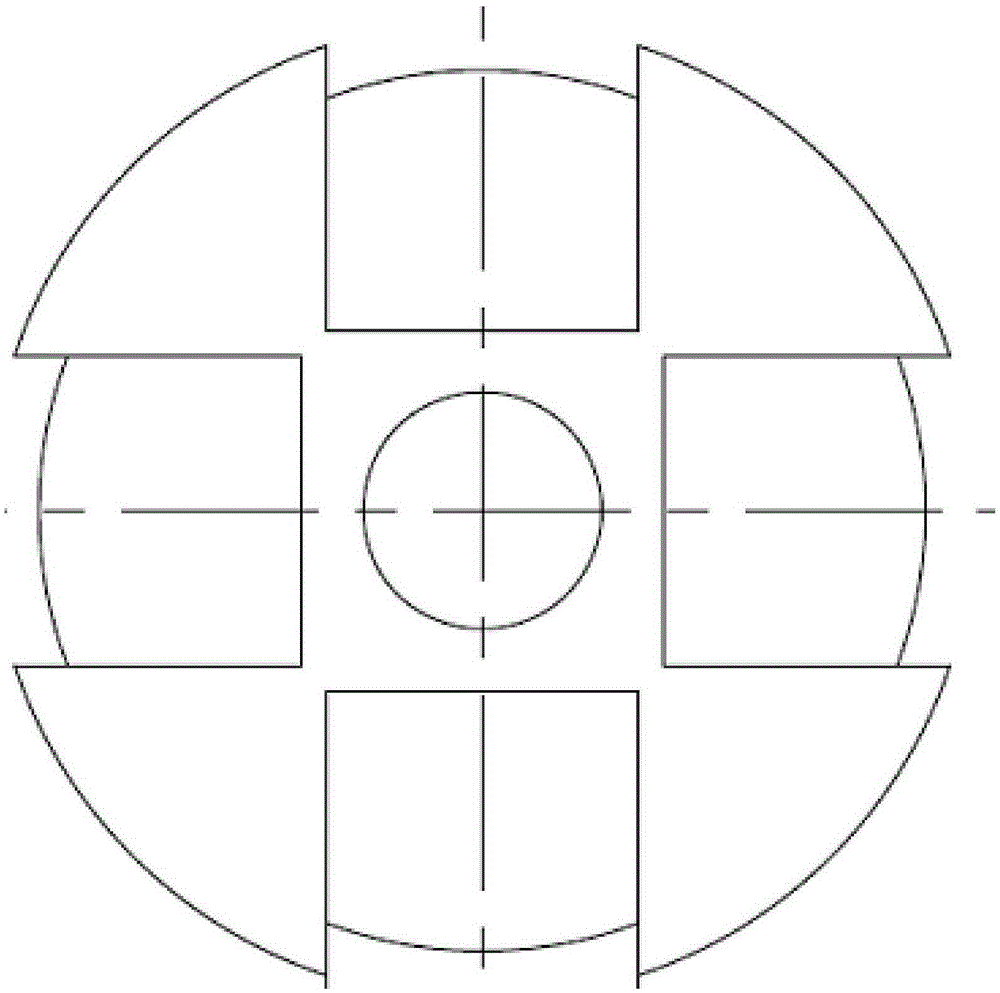

[0029] The shell is a cylindrical shell, and the inner diameter of the lower chamber of the shell is 10mm larger than the inner diameter of the upper chamber. There are seven polymer elastic elements 3, eight metal spacers 2, four wedge-shaped grooves on the outer surface of the wedge-shaped block installation cylinder 4, and four wedge-shaped blocks. The wedge-shaped angle between the wedge-shaped groove and the wedge-shaped block is the inclined plane and the horizontal plane. The included angle is 50°, the bottom surface of the wedge-shaped groove is an inclined plane, and the two sides of the groove are vertical planes.

Embodiment 2

[0031] The housing is a square cylindrical housing, and the inner diameter of the lower chamber of the housing is 10 mm larger than the inner diameter of the upper chamber. There are seven polymer elastic elements 3, eight metal spacers 2, two wedge-shaped grooves on the outer surface of the wedge-shaped block installation cylinder 4, and two wedge-shaped blocks. The wedge-shaped angle between the wedge-shaped groove and the wedge-shaped block is the inclined plane and the horizontal plane. The included angle is 45°, the bottom surface of the wedge-shaped groove is an inclined plane, and the two sides of the groove are vertical planes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com