High-efficiency installation method for pallet discharge machine of double-chamber lime shaft kiln

An installation method and discharge machine technology, applied in the field of high-efficiency installation of pallet discharge machines in double-chamber lime shaft kilns, can solve problems such as confusing installation methods, reduced work efficiency, and excessive pursuit of efficiency, so as to avoid separate installation and save energy. cost, the effect of solving rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

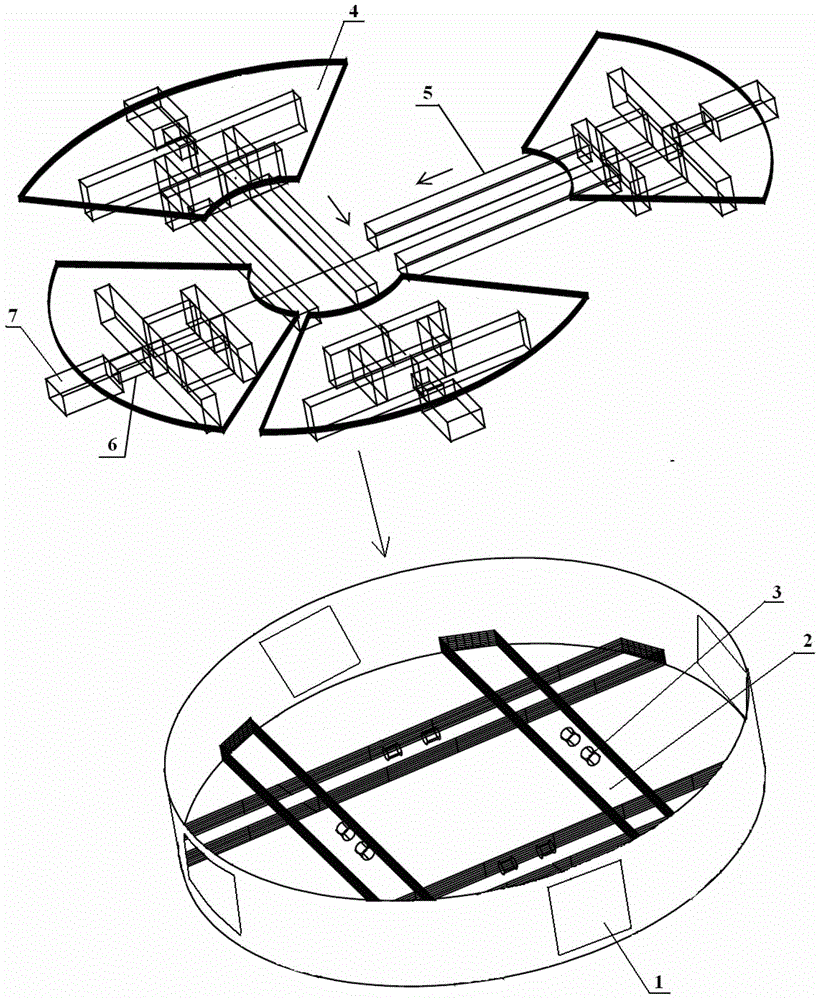

[0020] Such as figure 1 As shown, the high-efficiency installation method of the double-chamber lime shaft kiln supporting plate discharger of the present invention comprises the following steps:

[0021] First, make permanent marking points on the upper edges of the four hydraulic cylinder square holes 1 in the lower part of the unloading device, and the two permanent marking points at relative positions are on a horizontal axis. Three radial permanent marking points are respectively made on the upper surfaces of the four fan-shaped plates 4 of the pallet discharge machine, and are evenly distributed.

[0022] Secondly, place the parts of the pallet discharge machine according to the order of combination, fix a fan-shaped plate 4 at one end of the upper and lower two sets of connecting beams 5 of the pallet discharge machine, and hoist them to the predetermined posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com