125°C-resistant halogen-free flame-retardant thermoplastic elastomer ev cable material and preparation method

A thermoplastic elastomer and cable material technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of polymer structure damage, easy decomposition or volatilization, poor gasoline resistance, etc., and achieve low production costs , Improve gasoline resistance, improve temperature resistance and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

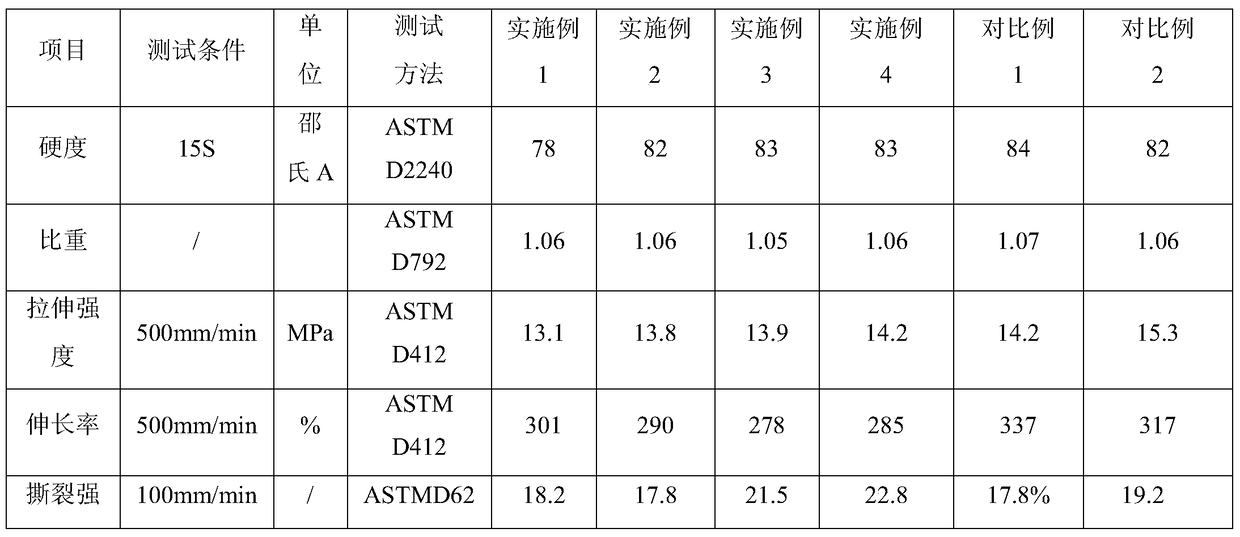

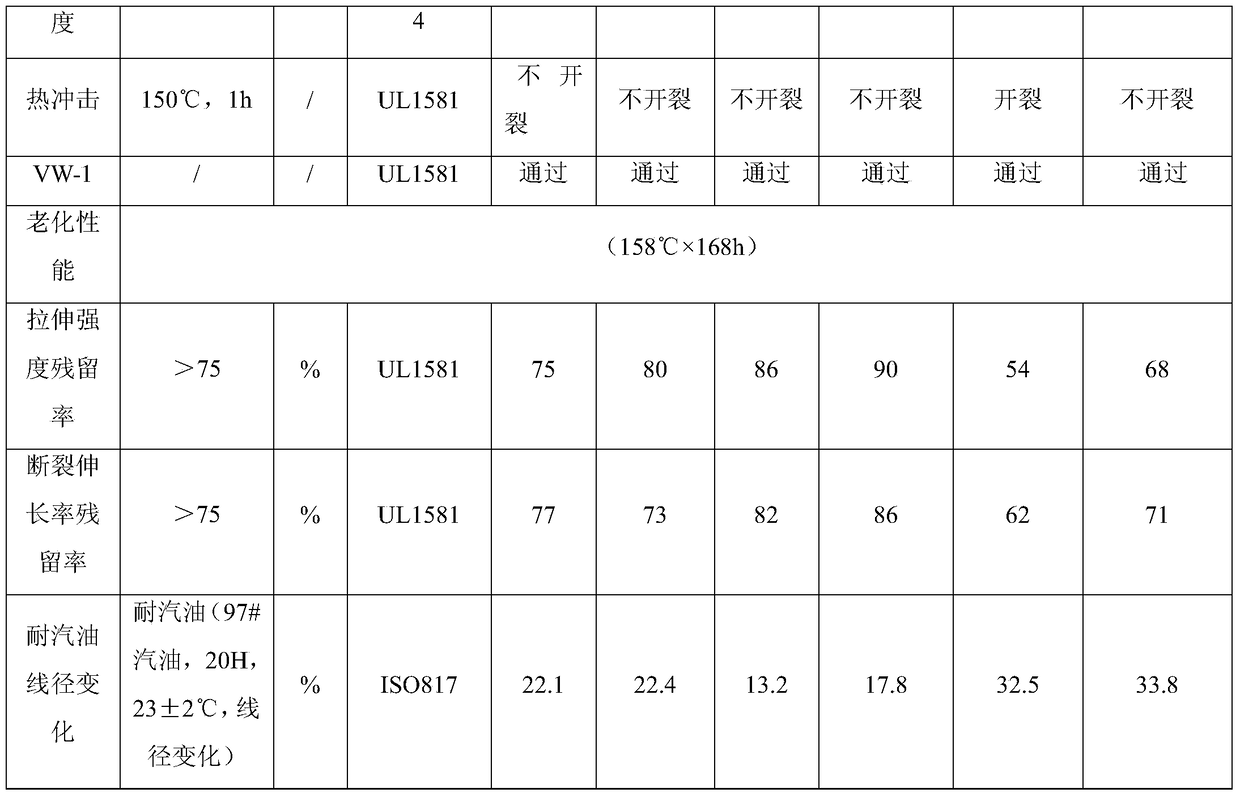

Examples

Embodiment 1

[0039] A method for preparing a 125°C-resistant halogen-free flame-retardant thermoplastic elastomer EV cable material, comprising the following steps:

[0040] 1) First pour the elastomer resin into the high-speed mixer, pour in the filler oil while stirring at high speed, and stir for 2 minutes;

[0041]2) After the oil filling is completed, add polyolefin resin, polyphenylene ether resin, acrylate rubber, flame retardant, crosslinking agent, auxiliary crosslinking agent and other additives, and discharge after stirring evenly;

[0042] 3) Put the uniformly mixed raw materials into a twin-screw extruder for melt kneading and extrude granulation (the main engine speed of the twin-screw extruder is 500r / min, and the extrusion temperature is 170°C), and finally a 125°C resistant Grade halogen-free high flame retardant thermoplastic elastomer wire and cable compound;

[0043] In this cable material, comprise the raw material of following weight part:

[0044] 15 parts of polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com