Longitudinal pushing structure of closure segment of continuous rigid frame bridge

A technology for closing sections and rigid frame bridges, which is applied in the field of longitudinal jacking structures for closing sections of continuous rigid frame bridges, which can solve the problems of long time consumption, small space for jacking operations, and increased costs, and achieve simplification and reduction of installation and dismantling work. The effect of improving operation difficulty and pushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

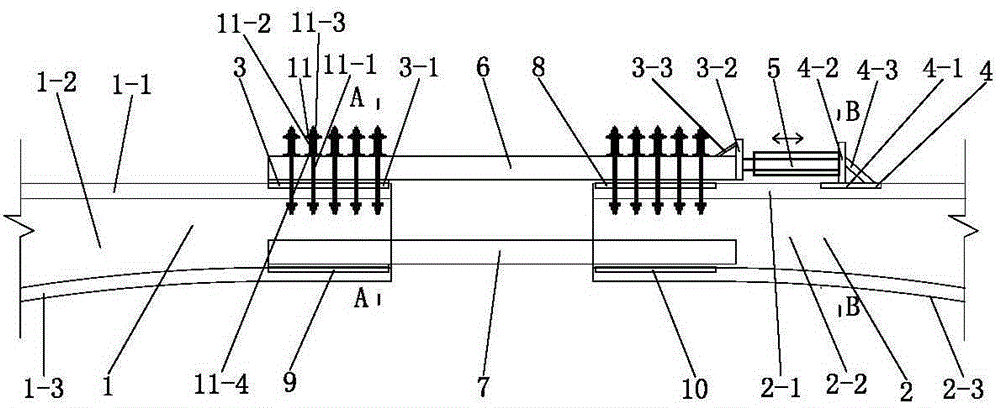

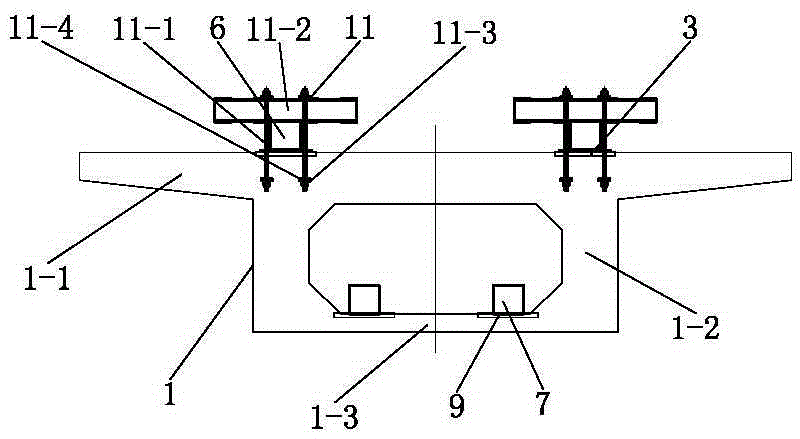

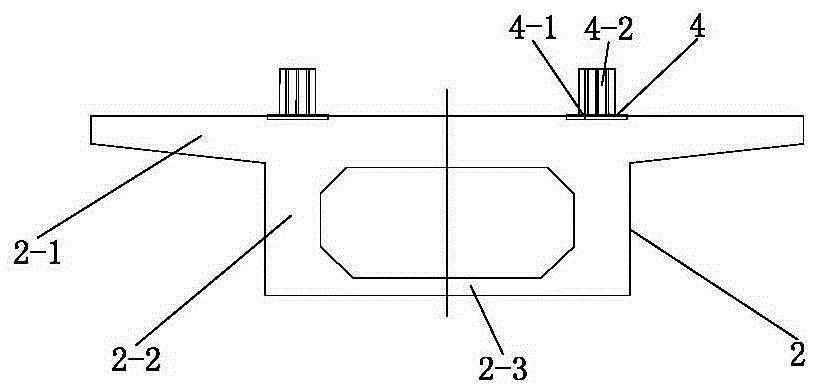

[0061] like Figure 1 to Figure 3 As shown, the longitudinal push structure of a continuous rigid frame bridge closing section provided by this embodiment includes a left main girder 1 and a right main girder 2, the left main girder 1 is fixed with a left push supporting part 3, and the right main girder The main beam 2 is fixed with a right push support part 4, and the left push support part 3 and the right push support part 4 are pushed and connected by a push part 5, and the left push support part 3 is connected with the right push support part 4. The top surface of the left main beam 1 is fixedly connected, and the right push support member 4 is fixedly connected with the top surface of the right main beam 2 . As a preference, from figure 1 It can be seen from the figure that the pushing part 5 is a jack, and the jack is a hydraulic jack, a screw jack, or a scissor jack.

[0062] In this embodiment, since the left push support part is fixedly connected to the top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com