New transmission screw pump

A driving screw, a new type of technology, applied in the direction of pumps, pump components, rotary piston type/swing piston type pump components, etc., can solve the problem of affecting the service life and quality of the whole machine, the overall structure of the screw pump is complex, and the transmission device is easy to wear, etc. problems, to achieve the effect of saving materials, simple and novel and unique structure, and beautifying the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

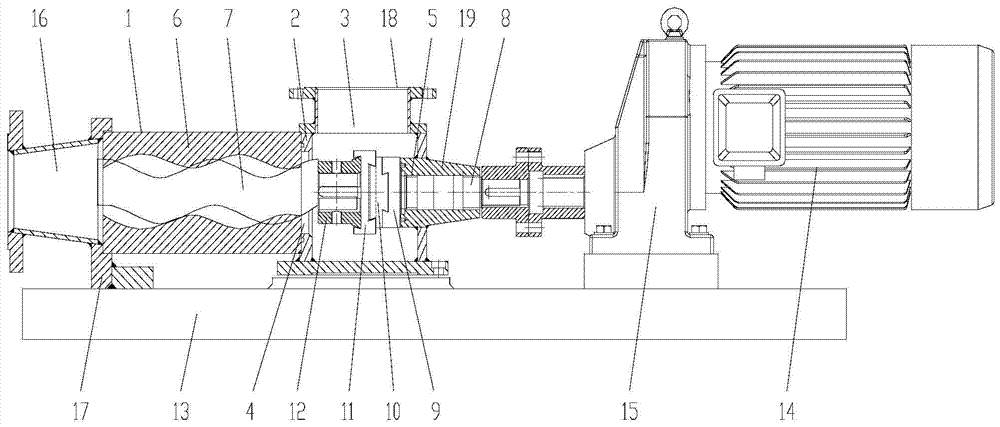

[0018] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the novel transmission screw pump of this embodiment includes a pump body 1 and a feed box body 2; the feed box body 2 is provided with a feed port 3 and a discharge port 4 and the power input port 5, the feed box body 2 is fixed on the feed end of the pump body 1 stator 6 and its discharge port 4 communicates with the feed port 3 of the stator 6; the power input port of the feed box body 2 There are 5 sealed and fixed cylindrical bearing seats 19; the bearing seat 19 is integrated with the feed box 2, and the original bearing installation structure with complex structure, large volume, high cost and easy leakage is cancelled, the overall length is greatly shortened, and Bearings can be assembled in the bearing housing 19, which is compact and simple as a whole, which eliminates the leaking structure, saves a lot of materials, and reduces the cost; the feeding port 3 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com