Quickly-assembled nut

A nut and nut sleeve technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of complicated and time-consuming nut and bolt connection operations, and achieve the effects of simple operation, time saving and efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

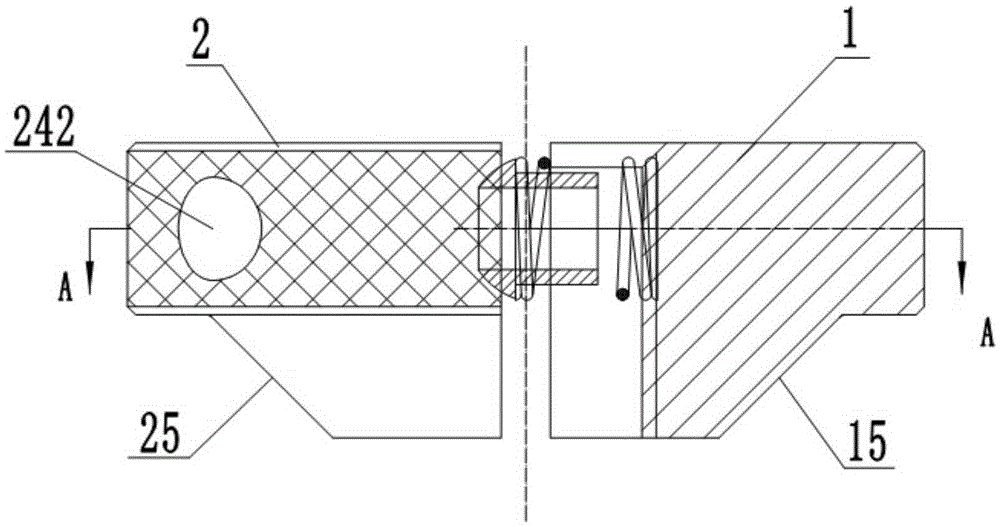

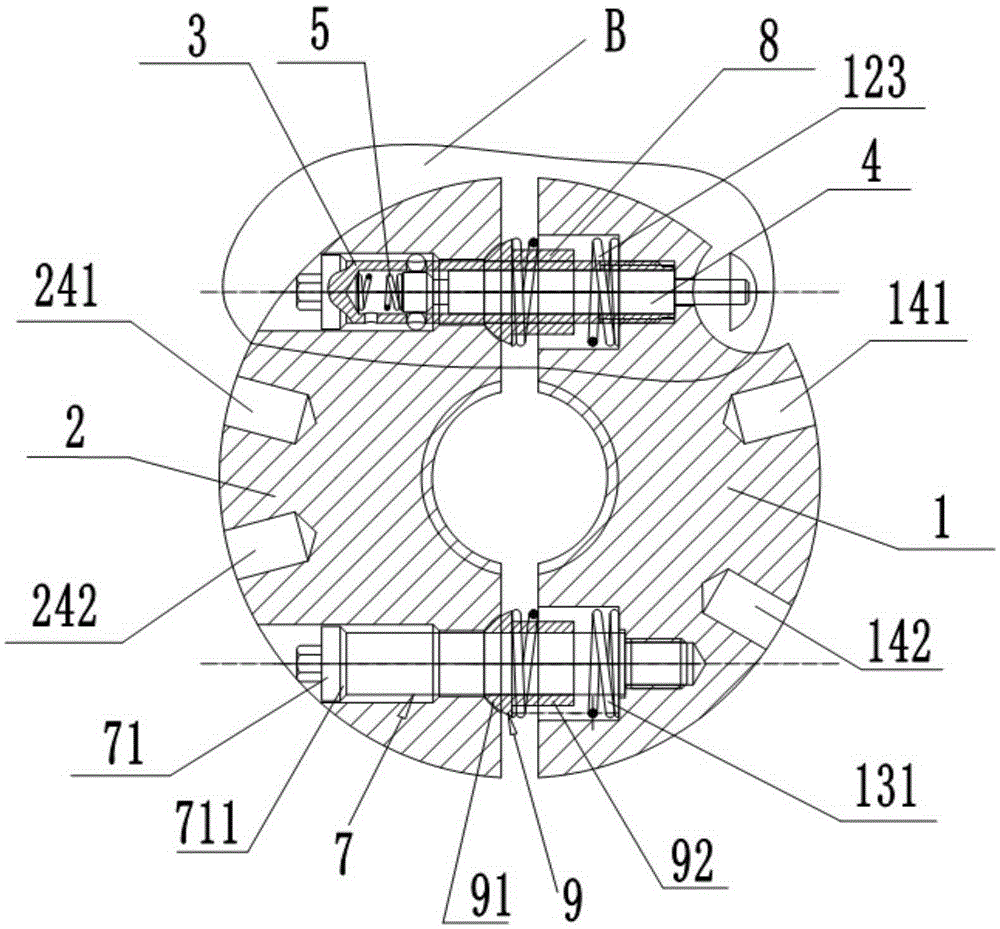

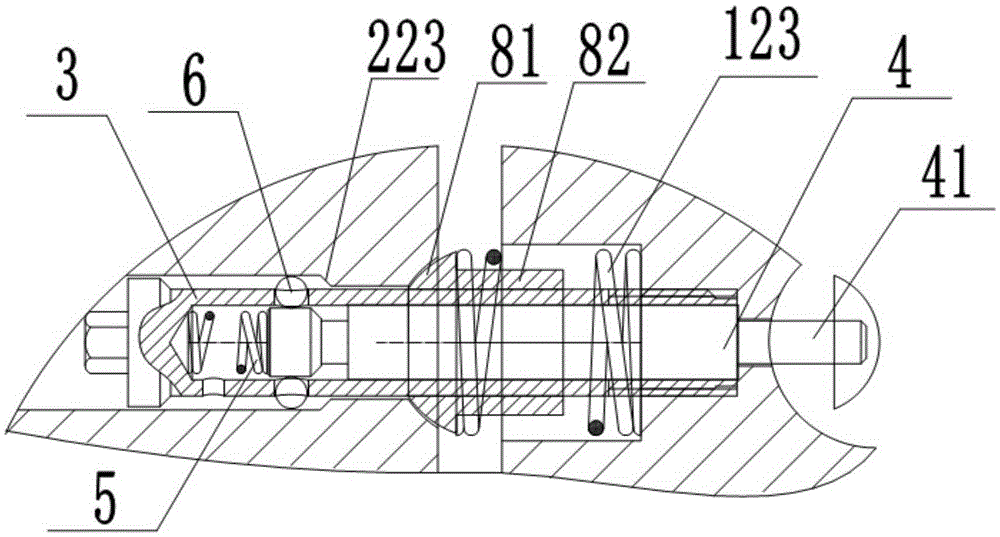

[0046] figure 1 It is a structural schematic diagram of a quick-fit nut according to an embodiment of the present invention, figure 2 for figure 1 A cross-sectional view of the quick nut in A-A. Such as figure 1 and figure 2 As shown, the quick-fit nut of the present invention includes a first nut sleeve 1, a second nut sleeve 2, a locking sleeve 3, a first guide pin 4, a first spring 5, a ball 6 and a second guide pin 7 .

[0047] Such as Figure 4 As shown, the first nut sleeve 1 has a concave first arc surface 11 , and the first arc surface 11 has an internal thread 111 . The first nut buckle 1 also has a second arc surface 14, the second arc surface 14 is parallel to the first arc surface 11, and the radius of the second arc surface 14 is greater than the radius of the first arc surface 11 . The first nut sleeve 1 has a first assembly hole 12 and a second assembly hole 13, the first assembly hole 12 and the second assembly hole 13 are respectively located on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com