Industrial flue gas waste heat recovery device based on liquid metals

A waste heat recovery device and liquid metal technology, applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of increasing the processing pressure of downstream equipment, increasing the flow rate of acetylene flue gas, and increasing costs. Achieve the effects of reducing the processing pressure, fully exchanging heat, and enhancing the effect of heat exchanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

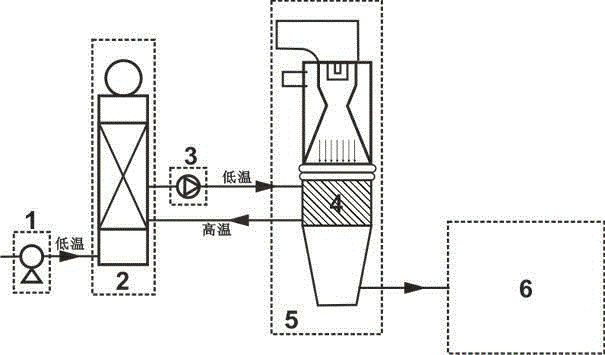

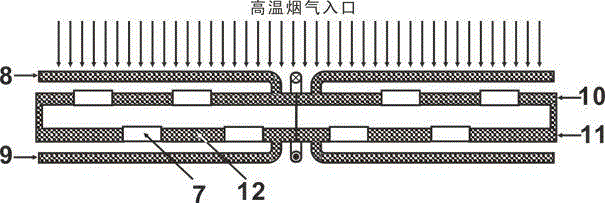

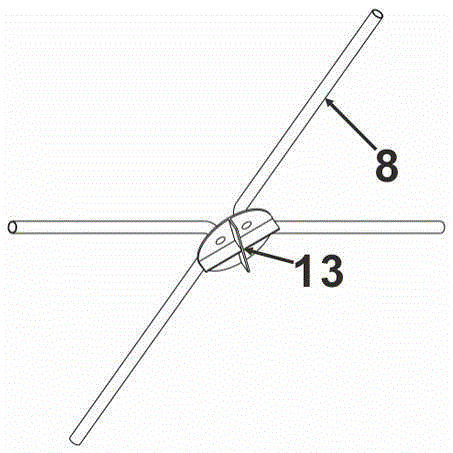

[0041] Example 1 shows a typical application of the liquid metal-based industrial flue gas waste heat recovery device of the present invention. figure 1 It is a structural schematic diagram of an industrial flue gas waste heat recovery device based on liquid metal. figure 2 It is a schematic diagram of the structure of the basic heat exchange unit of the heat exchanger. image 3 It is a schematic diagram of the cross-sectional structure of the basic heat exchange unit of the heat exchanger. Figure 4 It is a schematic diagram of the structure of the cross-shaped baffle in the basic heat exchange unit. Among them: 1 is softening water pump, 2 is steam boiler, 3 is electromagnetic pump, 4 is heat exchanger, 5 is industrial quenching treatment, 6 is product follow-up treatment, 7 is through hole, 8 is liquid metal inlet, 9 is liquid metal Outlet, 10 is an upper cold plate, 11 is a lower cold plate, 12 is liquid metal, and 13 is a cross-shaped baffle.

[0042] This is an indus...

Embodiment 2

[0058] figure 1 It is a structural schematic diagram of an industrial flue gas waste heat recovery device based on liquid metal. figure 2 It is a schematic diagram of the structure of the basic heat exchange unit of the heat exchanger. image 3 It is a schematic diagram of the cross-sectional structure of the basic heat exchange unit of the heat exchanger. Figure 4 It is a schematic diagram of the structure of the cross-shaped baffle in the basic heat exchange unit. Among them: 1 is softening water pump, 2 is steam boiler, 3 is electromagnetic pump, 4 is heat exchanger, 5 is industrial quenching treatment, 6 is product follow-up treatment, 7 is through hole, 8 is liquid metal inlet, 9 is liquid metal Outlet, 10 is an upper cold plate, 11 is a lower cold plate, 12 is liquid metal, and 13 is a cross-shaped baffle.

[0059] This is an industrial flue gas waste heat recovery device based on liquid metal in an embodiment, which is characterized in that it consists of a softeni...

Embodiment 3

[0076] figure 1 It is a structural schematic diagram of an industrial flue gas waste heat recovery device based on liquid metal. figure 2 It is a schematic diagram of the structure of the basic heat exchange unit of the heat exchanger. image 3 It is a schematic diagram of the cross-sectional structure of the basic heat exchange unit of the heat exchanger. Figure 4 It is a schematic diagram of the structure of the cross-shaped baffle in the basic heat exchange unit. Among them: 1 is softening water pump, 2 is steam boiler, 3 is electromagnetic pump, 4 is heat exchanger, 5 is industrial quenching treatment, 6 is product follow-up treatment, 7 is through hole, 8 is liquid metal inlet, 9 is liquid metal Outlet, 10 is an upper cold plate, 11 is a lower cold plate, 12 is liquid metal, and 13 is a cross-shaped baffle.

[0077] This is an industrial flue gas waste heat recovery device based on liquid metal in an embodiment, which is characterized in that it consists of a softeni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap