Multi-stage filtering device used for removing oil fume

A technology of stage filtration and stage filter, which is applied in the field of oil fume separation and purification, can solve the problems of difficult replacement and waste water treatment, reduction, and difficult removal of air oil components, etc., to improve the purification effect of oil fume, good effect, and good filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

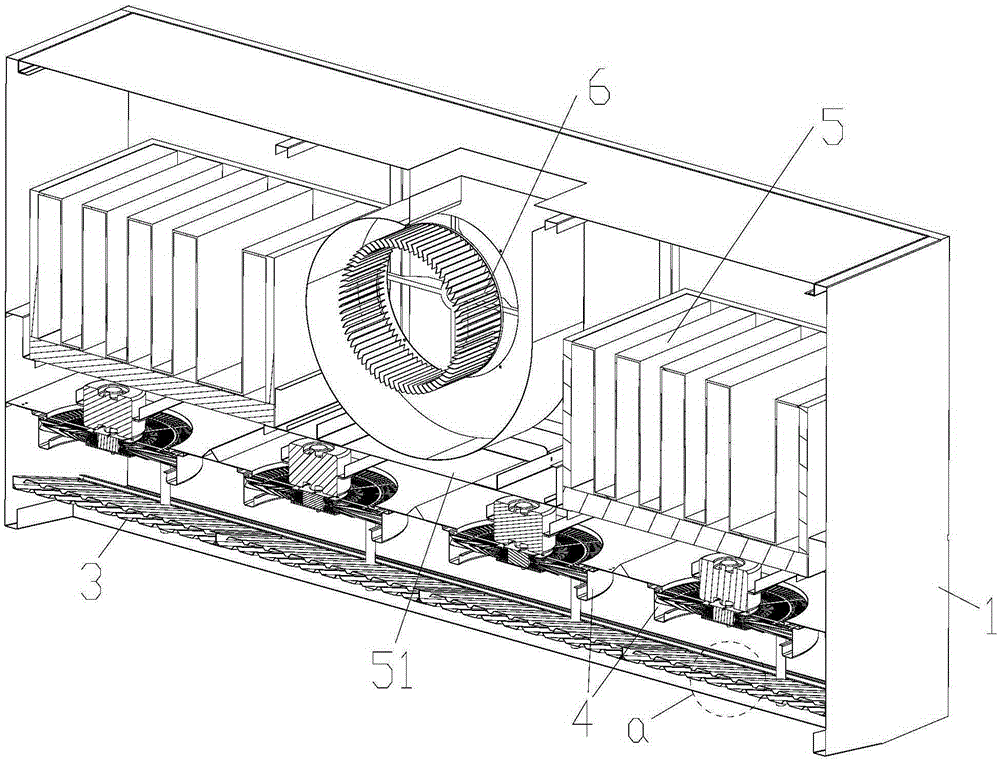

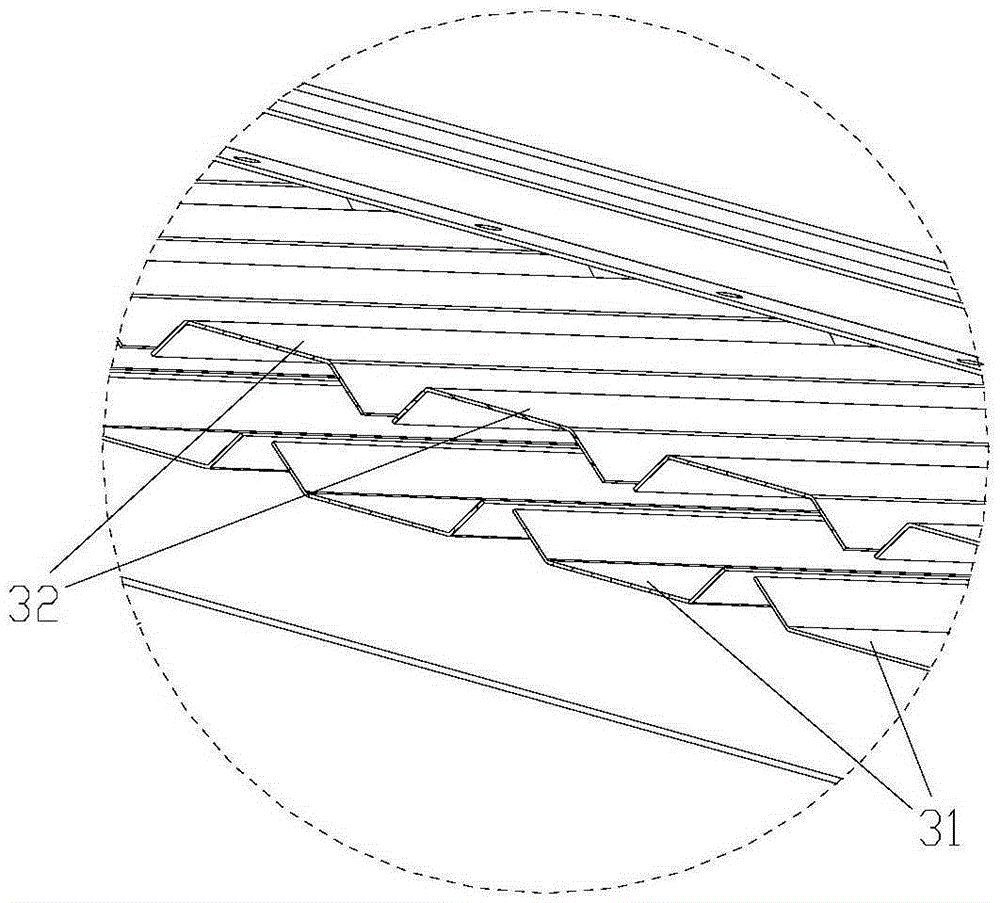

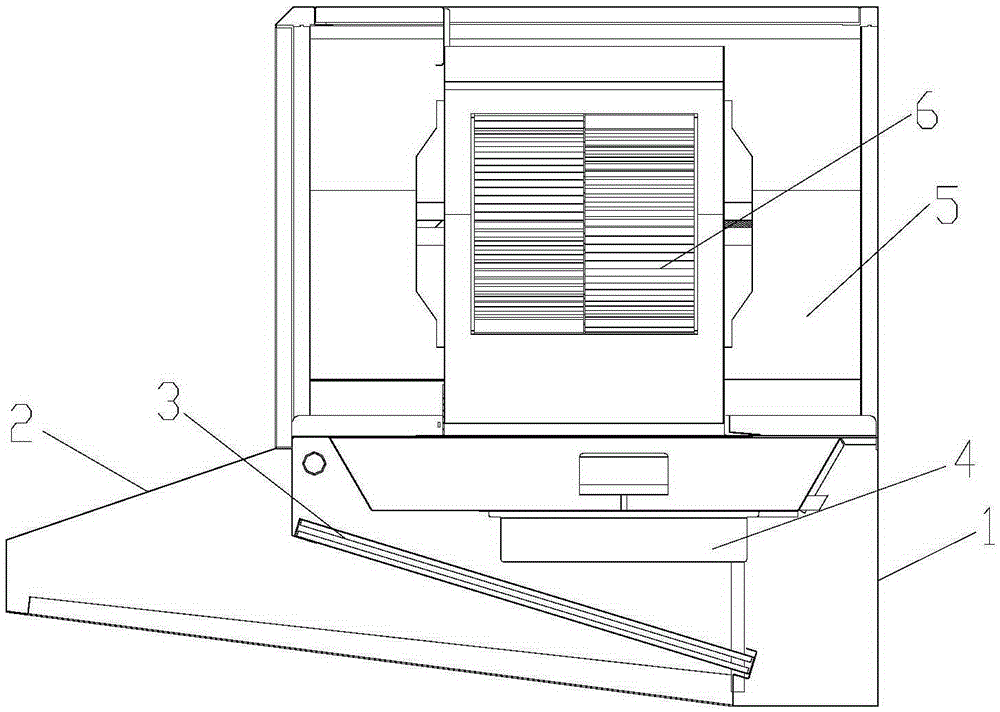

[0030] to combine Figure 1-Figure 3 As shown, the present application proposes a multi-stage filter device for oil fume removal. The multi-stage filter device includes a housing 1 and a fan 6 installed in the housing 1 for providing negative pressure suction. Opening, the oil fume passage is formed between the opening of the casing 1 and the fan 6, and the oil fume collecting cover 2 and the vapor-liquid barrier assembly 3 installed under the casing 1 are arranged in sequence on the oil fume passage, and installed in the casing 1 At least one gas-liquid separation assembly 4 and a multi-stage filter 5.

[0031] Among them, a vapor-liquid separation chamber is formed between the vapor-liquid barrier assembly 3 and the vapor-liquid separation assembly 4, a vapor-liquid separation chamber is formed between the vapor-liquid separation assembly 4 and the multi-stage filter 5, and the multi-stage filter 5 and the fan 6 The part of the cavity where it is located is the filter cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com