Drying device for producing foamed ceramic powder

A drying device and a technology for foaming ceramics, applied in the field of refractory insulation materials, can solve the problems of speeding up drying efficiency, increasing energy consumption, large energy consumption, etc., and achieving the effect of improving drying efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

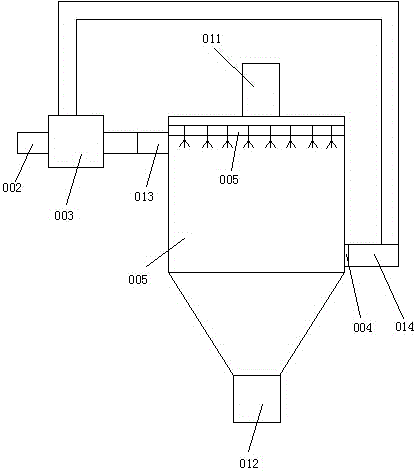

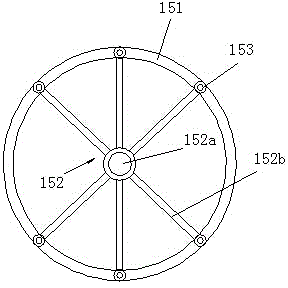

[0010] A drying device for producing foamed ceramic powder, comprising a conical shell 001, a hot air port 011 at the top of the shell 001, a discharge port 012 arranged at the bottom of the shell, and a feed port 013 on the upper side wall of the shell , the air outlet 014 on the side wall of the lower end of the housing and the spray pipe 015 connected to the feed port 013, the feed port 013 is connected to the feed pipe 002, and the feed pipe 002 is provided with a tubular heat exchanger 003, The pipe heat exchanger 003 is connected to the air outlet 014. A filter 004 is provided at the air outlet 014 . The spray pipe 015 includes a spray frame 151, a spray pipe 152 and a nozzle 153. The spray frame 151 is annularly arranged along the inner wall of the housing 001. The spray pipe 152 includes a main pipe 152a and a circle along the spray frame 151. The branch pipes 152b are arranged in a ring, and the nozzles 153 are installed on the branch pipes 152b.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap