Slag mechanism

A technology of impact mechanism and slag head, which is applied in the field of smelting equipment, can solve the problems of poor slag pounding effect, low tamping head insertion speed, and small impact force, etc., and achieve good slag pounding effect, guaranteed durability, and large impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

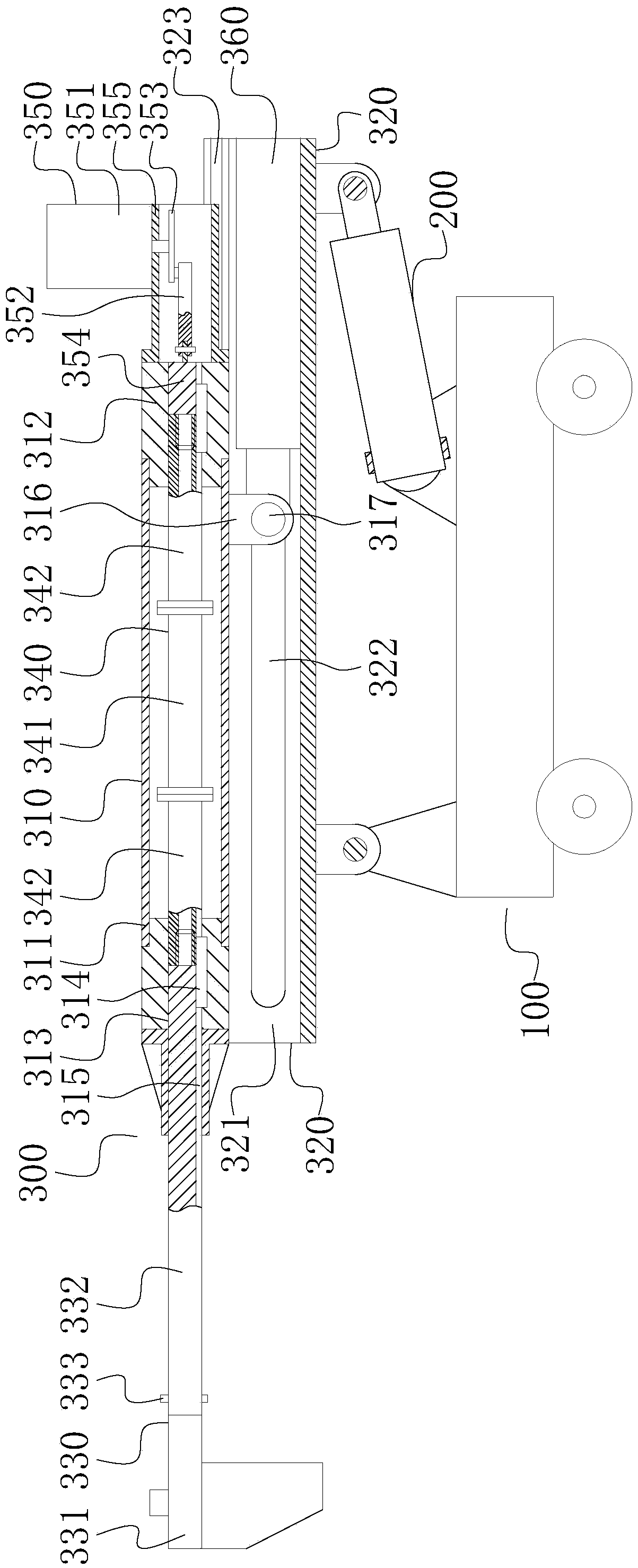

[0015] The slag breaking mechanism of the present invention includes a telescopic arm 310, a support arm 320, a tamping head 330, a guide rod 340, an impact mechanism 350, and a telescopic oil cylinder 360; The telescopic oil cylinder 360 is installed between the support arm 320 and the telescopic arm 310; the guide rod 340 is mounted on the telescopic arm 310 and is slidably matched with the telescopic arm 310; the ram 330 is mounted on one end of the guide rod 340; The mechanism 350 is installed on the telescopic arm 310 and connected with the other end of the guide rod 340 opposite to the ram 330 .

[0016] Such as figure 1 As shown, the slag breaking machine adopting the slagging mechanism of the present invention, when in use, the slagging mechanism 300 of the present invention is installed on the running gear 100 via the turning mechanism 200 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com