Automatic overhead distribution line live-line maintenance and reconstruction device

A technology of power distribution lines and automatic devices, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficult implementation, high cost, safety and work efficiency, etc., and achieve good deceleration effect, light weight, Ease of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be described in further detail below according to the drawings and embodiments.

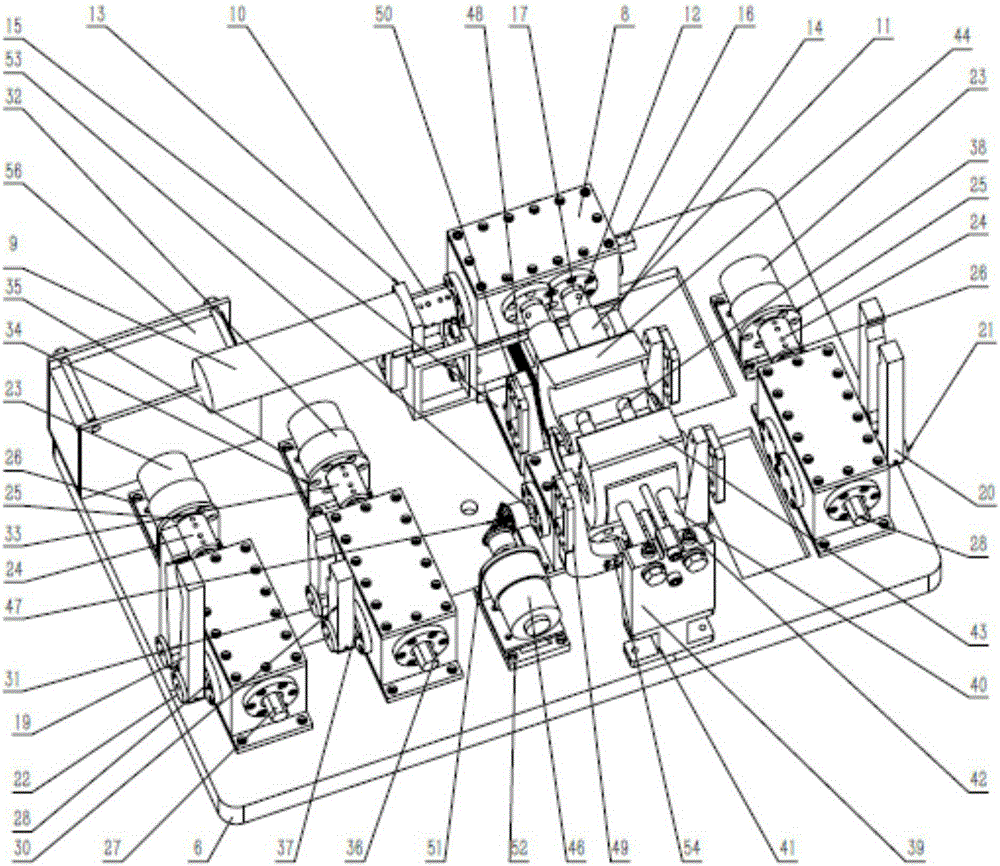

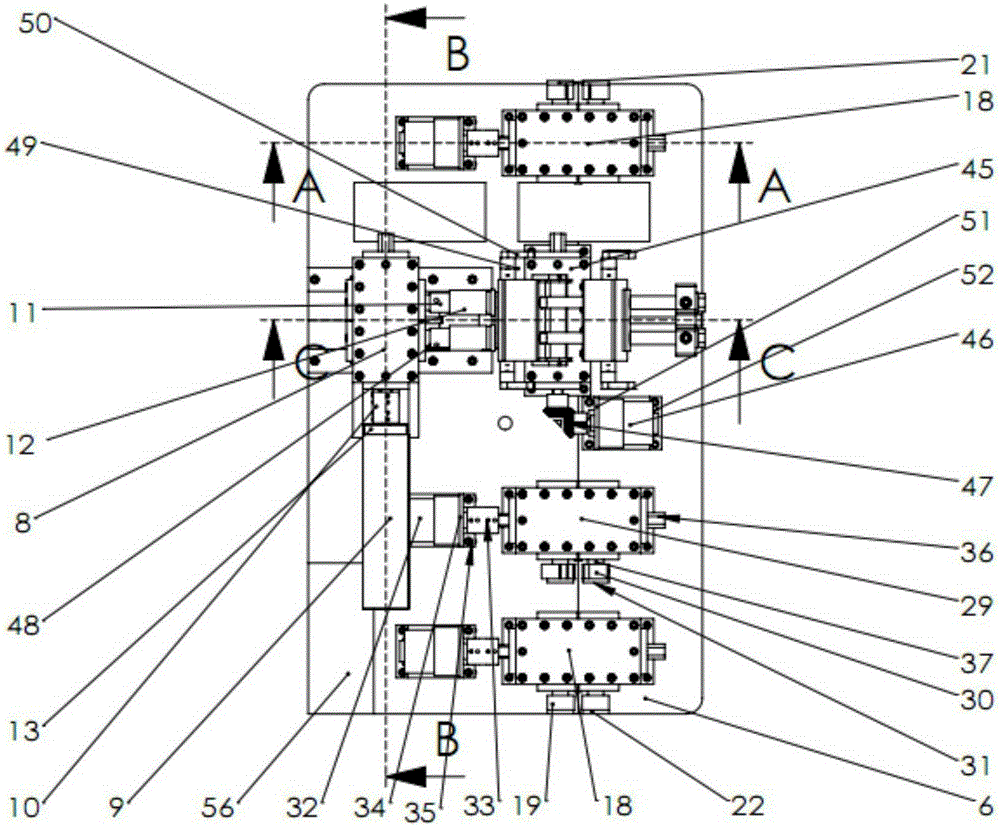

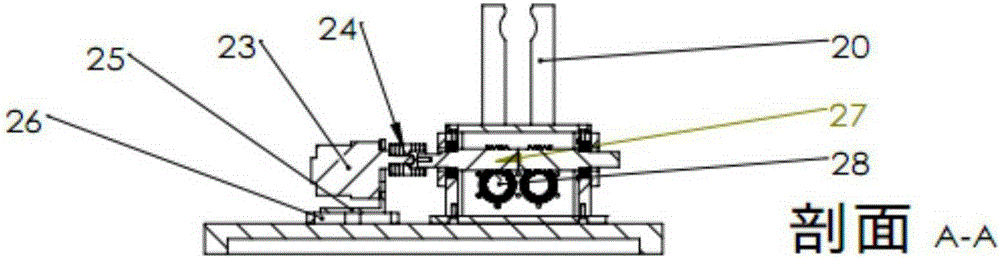

[0035] refer to Figure 1-Figure 5 , the present invention, an automatic device for live splicing of overhead power distribution lines, comprising a bolt fastening mechanism assembly 1, a main line clamping mechanism assembly 2, a secondary line clamping mechanism assembly 3, and an insulation puncture wire Clamp assembly 4, wire clamp clamping mechanism assembly 5, bottom plate 6 has a groove 7 on the side close to the wire clamp clamping mechanism assembly 5 and the main wire clamping mechanism assembly 2 assembly, so as to observe and control the wire Robot operation, the bolt fastening mechanism assembly 1 assembly is screwed through two sleeve rod joints 68 and the hexagonal head bolt fine thread 60, and together with the wire clamp clamping mechanism assembly, the bolt is tightened to cooperate with the main line clamping mechanism Assembly assembly, auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com