Rolling element bearing with cage

A technology of rolling elements and cages, applied in the direction of ball bearings, bearing elements, shafts and bearings, can solve problems such as uselessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

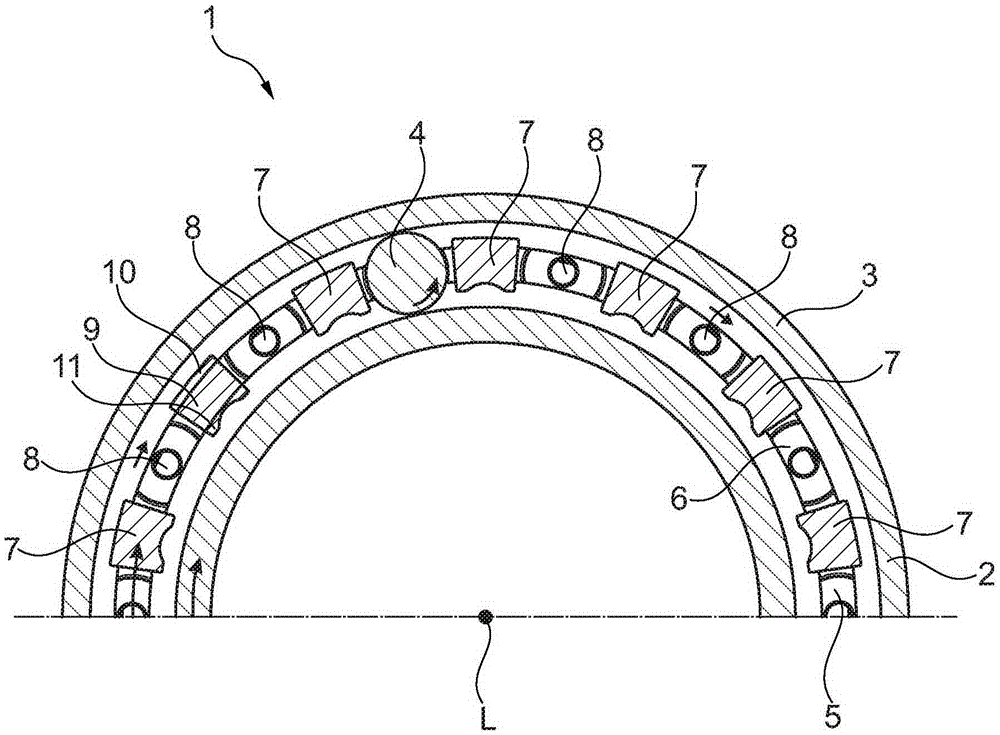

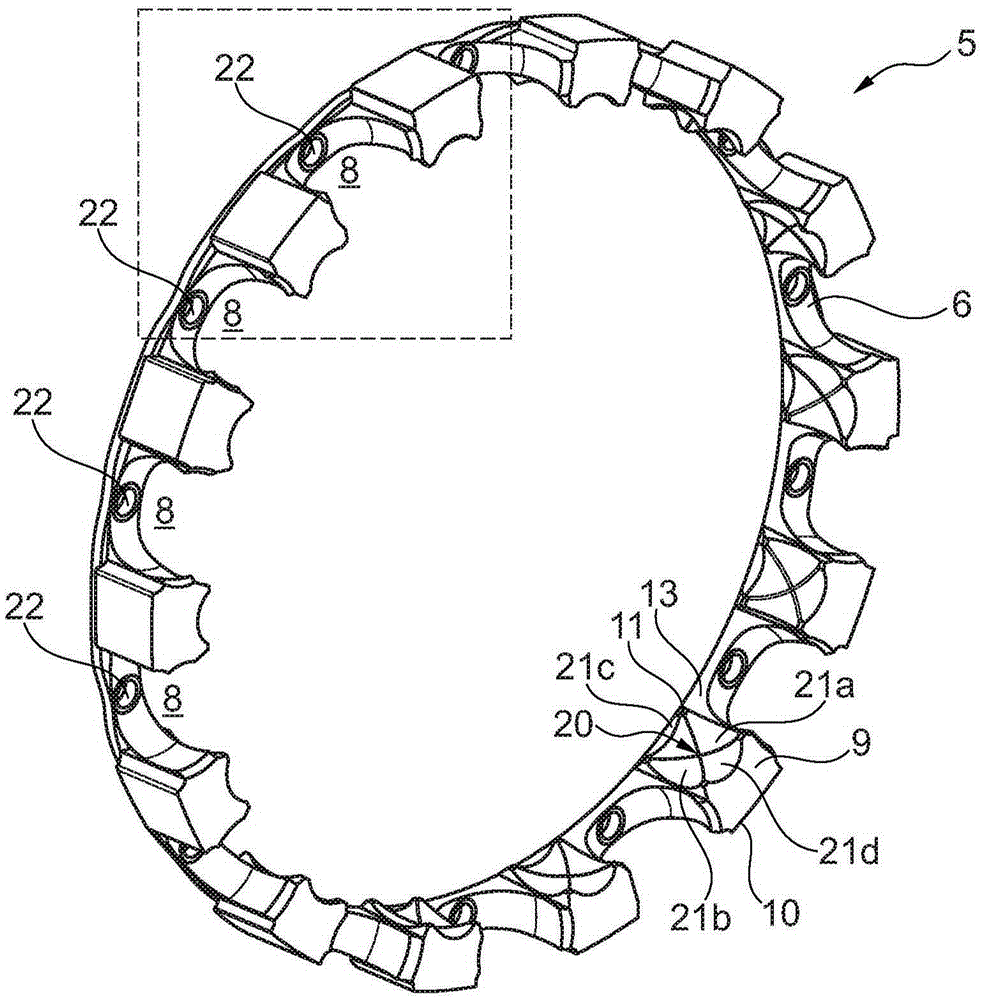

[0027] figure 1 A rolling element bearing 1 as an exemplary embodiment of the invention is shown in a schematic axial plan view, wherein only one half of the rolling bearing 1 is shown. The rolling element bearing 1 comprises an inner ring 2 and an outer ring 3 between which a plurality of balls 4 are arranged as rolling elements so that the inner ring 2 and the outer ring 3 face each other about a bearing axis L These balls roll on the raceways of rings 2 and 3 during twisting.

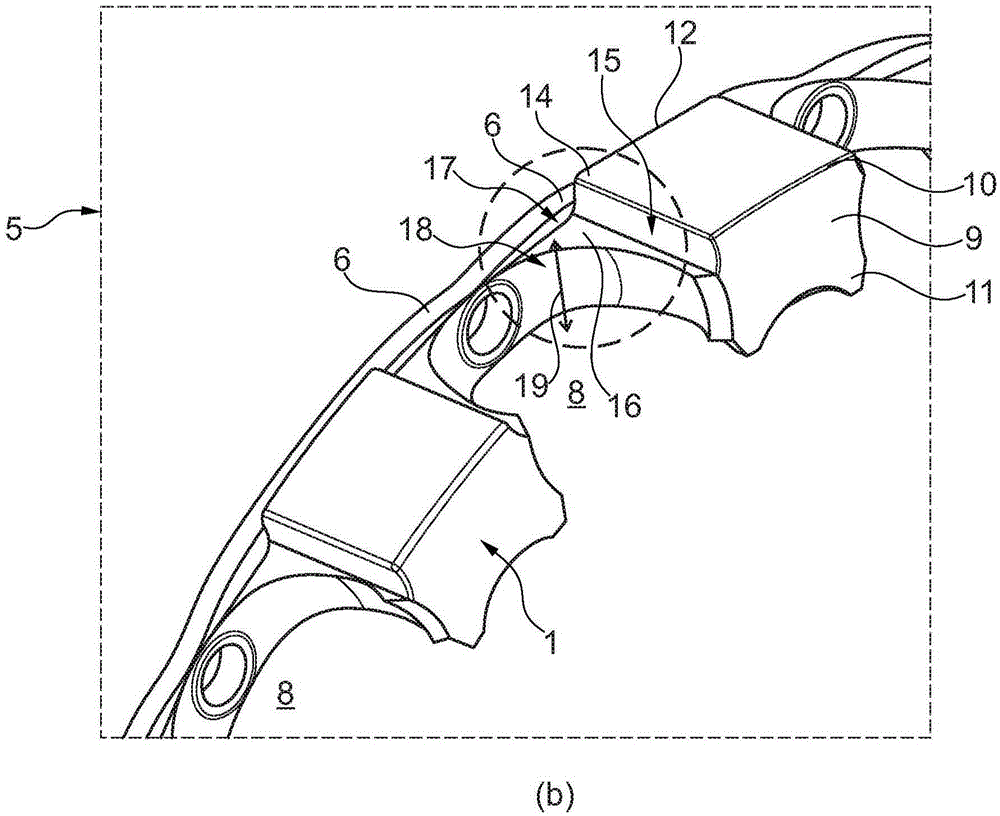

[0028] The rolling element bearing 1 comprises a cage 5, which is made of plastic. The cage 5 comprises a side ring section 6 which is designed as an annular disk extending in a radial plane perpendicular to the bearing axis L, and a plurality of web sections 7 which extend in the axial direction and are formed in the On the side ring section 6. The web sections 7 result in snap pockets 8 that are uniformly distributed in the circumferential direction, wherein each snap pocket 8 is delimited in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com