Bicycle steel bowl without lubricating grease

A bicycle and lubricating grease technology, which is applied to bicycle accessories, lubricating compositions, devices for coating liquid on surfaces, etc., can solve problems such as difficulty in disassembling components, aging, agglomeration, and inability for users to disassemble by themselves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

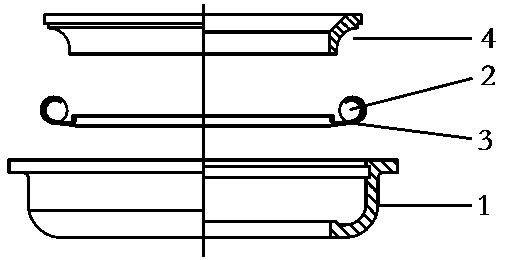

[0016] like figure 1 , figure 2 Shown, a kind of bicycle steel bowl without grease, including structure and preparation method.

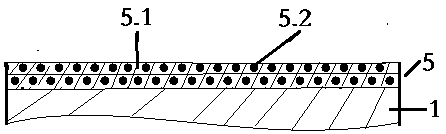

[0017] A structure of a bicycle steel bowl without grease, comprising a steel bowl seat 1, a steel ball 2, a steel ball clamp 3, an inner gear 4 and a nano-carbon ball solid lubricant 5, and the steel ball 2 is wrapped in a steel ball clamp 3, the steel ball clip 3 plays the role of equally dividing the distance between the steel balls 2, and the steel ball 2 and the steel ball clip 3 are placed between the steel bowl seat 1 and the inner shelf 4, and it is characterized in that: the steel bowl seat 1 , the frictional surfaces of the steel ball 2 and the inner gear 4 are all coated with nano-carbon sphere solid lubricant 5, and the nano-carbon sphere s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com