A uniform low-loss air path system and air flow organization method for a pneumatic seeder

An air system and air pressure technology, applied in the field of agricultural machinery, can solve the problems of uneven air distribution, large difference in the working effect of seed metering devices, and large air flow loss, etc., and meet the requirements of ensuring air tightness, high consistency, The effect of less air loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention is further described below in conjunction with embodiment.

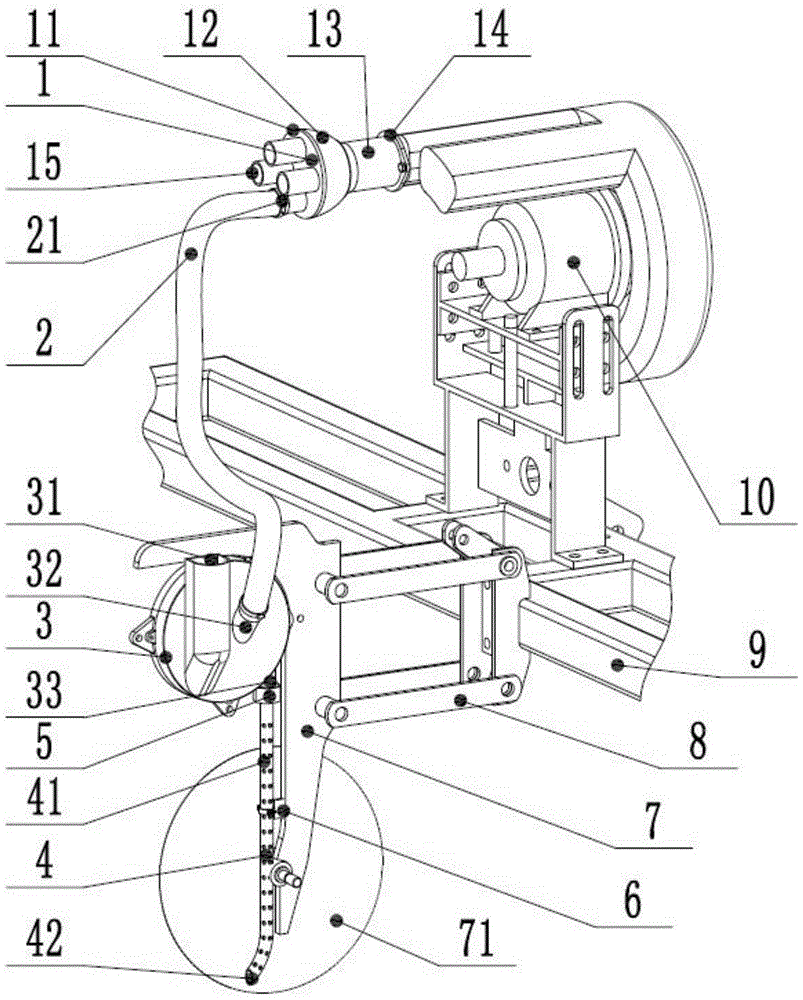

[0059] Such as figure 1 As shown, the uniform low-loss air path system of the pneumatic seeder of the present invention includes a vortex fan 10 , an air distributor 1 , an air hose 2 , a pneumatic seed meter 3 and a seed pipe 4 . Wherein, the vortex blower 10 is fixedly connected on the frame 9 .

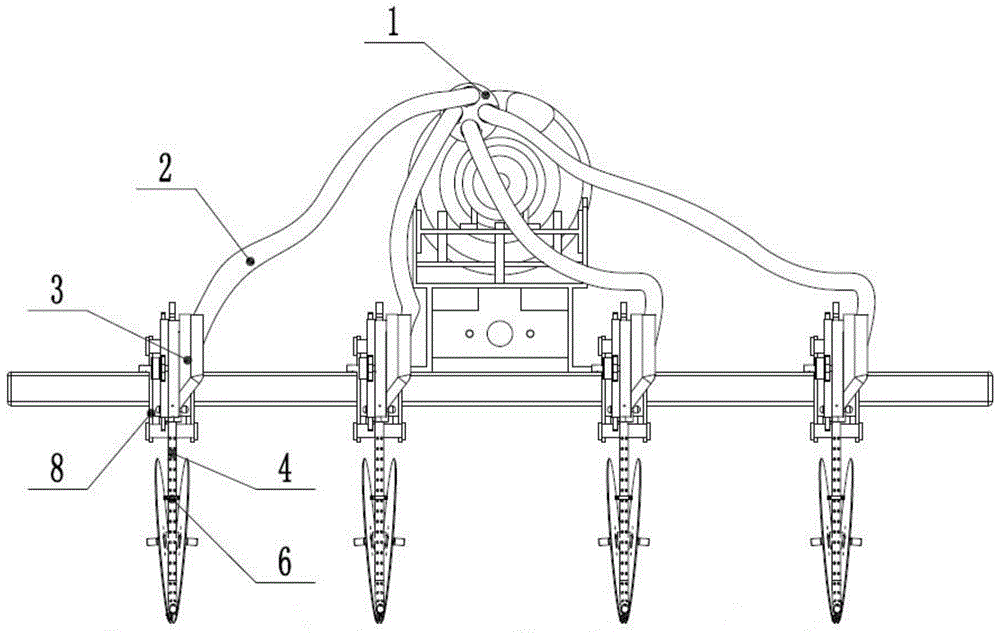

[0060] Such as figure 2 As shown, the seed metering unit composed of the pneumatic seed metering device 3 and the seed metering pipe 4 is fixedly connected to the frame 9 through the seed metering unit plate 7 and the parallel four-bar linkage mechanism 8 . Multiple groups of seed metering units are evenly and equidistantly distributed to both sides with the central axis of the vortex fan 10 as the center. Preferably, the number of seeding monomers is four groups.

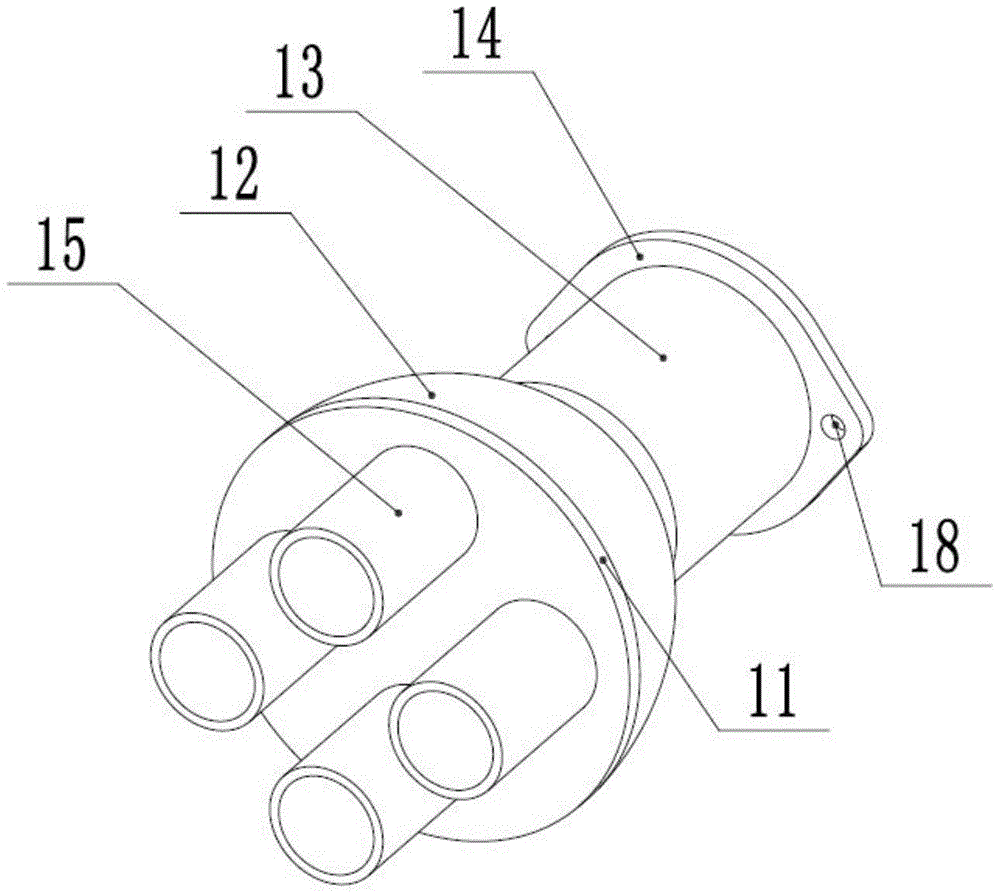

[0061] Such as image 3 with Figure 4 As shown, the airflow distributor 1 includes a distributor disk 11, a reducing join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com