Automatic open and close vegetable planter

A technology of automatic opening and closing, planting device, applied in the field of vegetable planting device and transplanting planting device, can solve the problems of ineffective reduction of parts, difficult alignment of the lower tip, affecting the planting effect, etc., and achieves easy assembly, simple structure, Collapse effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

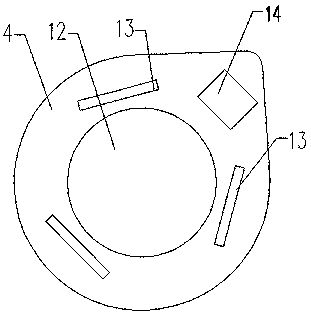

[0044] Example 1, as Figures 1 to 6 As shown, an automatic opening and closing vegetable planter includes a manual control assembly, a sliding assembly and a plurality of tongues 5, and the manual control assembly includes a control panel 4 with an upper transplanting hole 12 in the middle and a hand-held part;

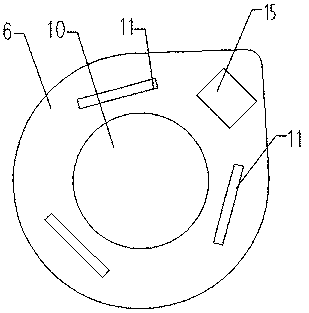

[0045] The sliding assembly includes a hanging plate 6 with a lower transplanting hole 10 in the middle, and the sliding assembly and the manual control assembly are connected in a relative sliding manner;

[0046] The upper transplanting hole 12 corresponds to the lower transplanting hole 10, and the axial distance between the upper transplanting hole 12 and the lower transplanting hole 10 is changed when sliding;

[0047] The hand-held component includes a vertical rod 9 fixed on the control panel and a handle at the top of the vertical rod 9. The lower end and the interior of the vertical rod 9 are hollow structures; one side of the hanging plate 6 is provided wit...

Embodiment 2

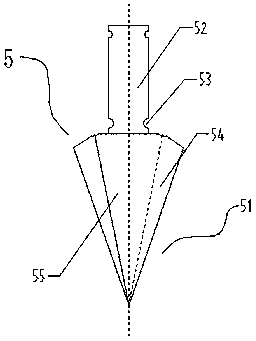

[0077] Embodiment 2, in above-mentioned embodiment 1, as Figure 7 As shown, there are three tongues, and the two sides of the bent portion 51 of each tongue are symmetrically folded inward to form two side pieces 54 and a base piece 55 , the side pieces 54 and the base piece 55 The included angle b between them is 140 degrees, and when the three tongue pieces 5 are contracted, the two sides of the adjacent bending parts 51 are in contact to form a nine-pyramid structure.

[0078] like Figure 8 As shown, when the three tongue pieces 5 are contracted, the two sides of the adjacent tongue pieces 5 are in contact to form a nine-pyramid structure. It can also achieve a better collapsing effect.

[0079] Whether it is a hexagonal pyramid or a nine pyramid, the position of the tongue guide hole 13 of the control panel 4 and the tongue limit hole 11 on the attachment plate 6 is different, and the diameter of the circumference enclosed by the three tongue guide holes 13 is differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com