Water paint spraying and curing device of thrust wheel

A technology of curing device and rollers, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as pinholes and paint film blooming, and achieve the effect of avoiding blooming and pinholes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

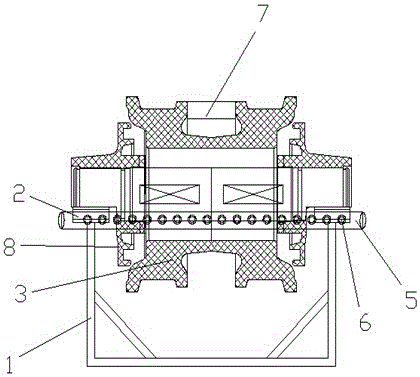

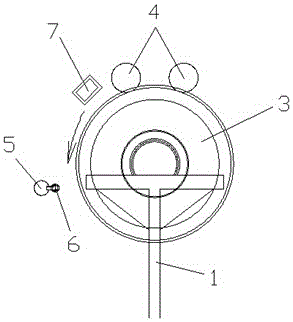

[0011] Attached below figure 1 and 2 The present invention is further described. attached figure 1 and 2 Schematically shows the water-based paint spray curing device for rollers of the present invention, including a bracket 1, on which a platform 2 is provided, and the rollers 3 are detachably fixed on the platform 2, and the platform 2 is provided with a heating device, a driving wheel 4, a spray gun rod 5 and a cooling circulating water device.

[0012] Preferably, the heating device is a high-frequency induction heating device.

[0013] Preferably, a profiling sensor 7 is provided on the surface of the roller 3 .

[0014] Preferably, several spray heads 6 are uniformly arranged on the spray gun rod 5 .

[0015] Fix the end cover 8 of the supporting wheel 3 on the platform 2 of the bracket 1, use the driving wheel 4 to drive the supporting wheel 3 to rotate, and use a high-frequency induction heating device to heat the surface of the supporting wheel 3 during the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com