A 4g base station aluminum alloy radiator profile extrusion die

An extrusion die and aluminum alloy technology, applied in the field of extrusion die for aluminum alloy radiator profiles of 4G base stations, can solve problems such as poor performance, improve smoothness and quality, reduce loss and energy consumption, and prevent wear or damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

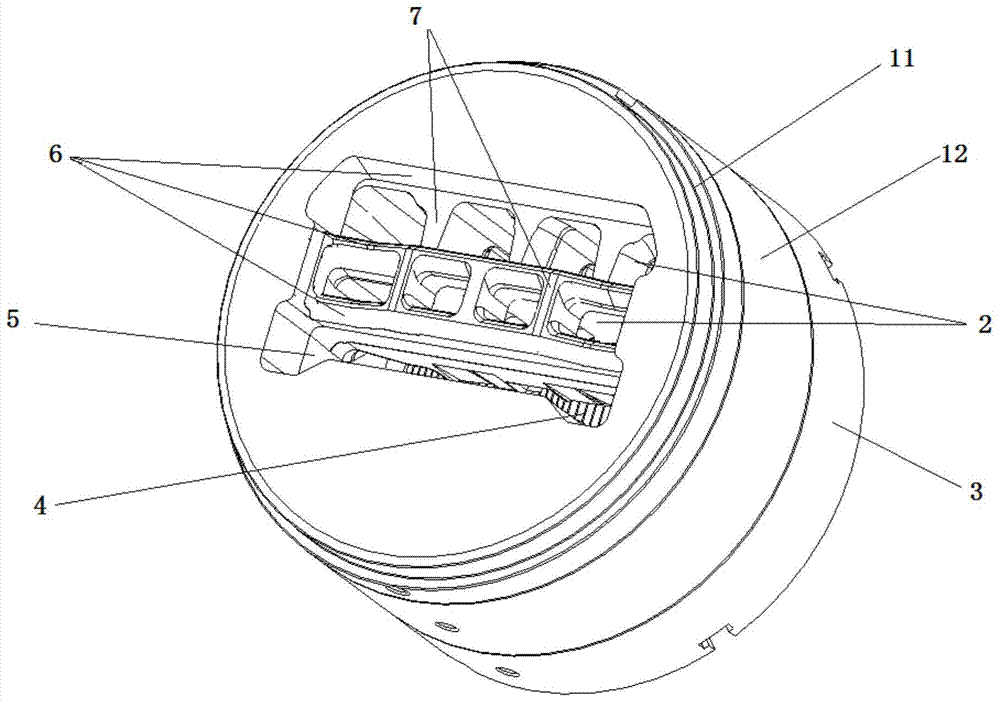

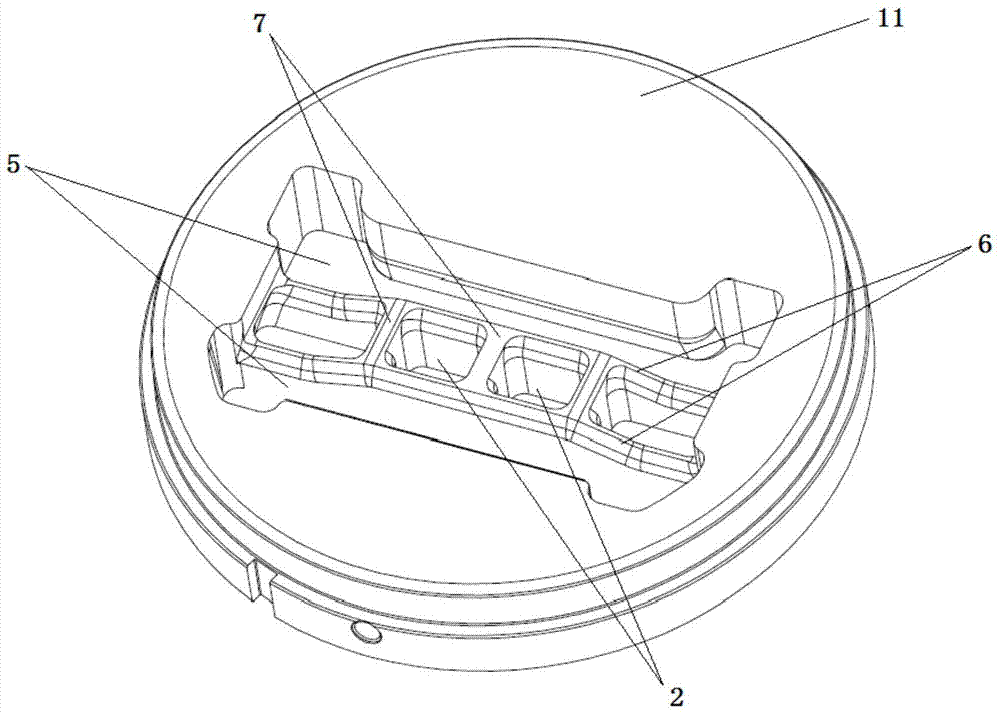

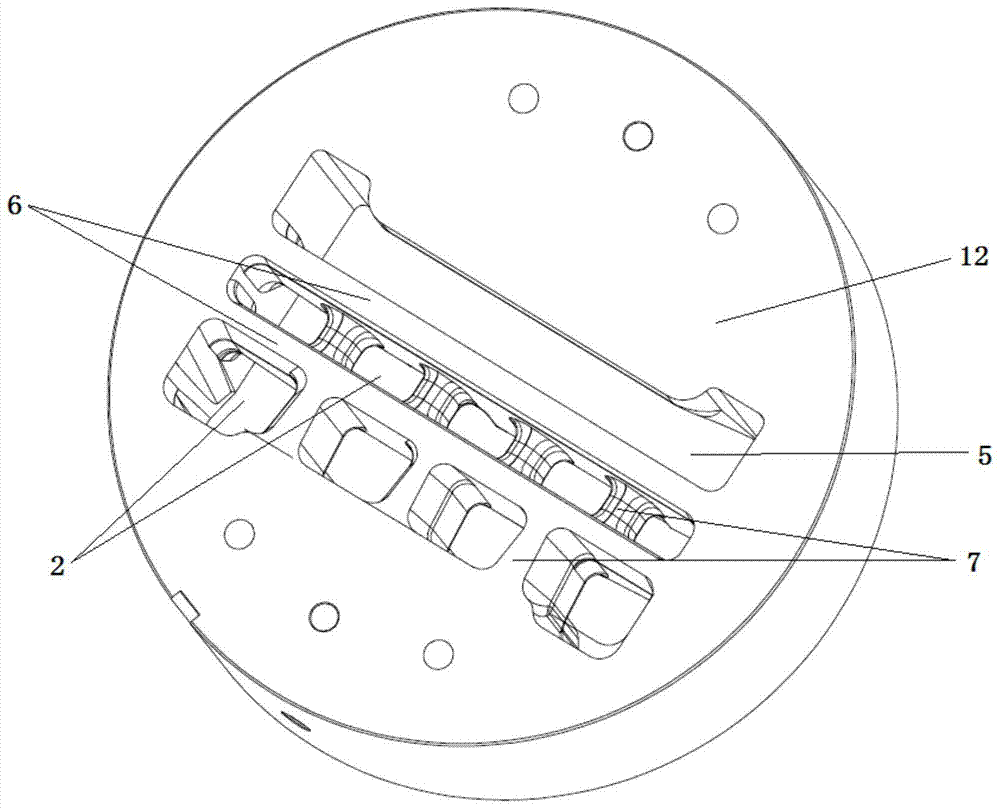

[0035] like Figure 1-8As shown, a 4G base station aluminum alloy radiator profile extrusion die includes two upper dies and a lower die 3, the upper die and the lower die 3 are superimposed to form an extrusion die, and the end face of the upper die is provided with a feed The feed port is provided with a diversion hole 2 and a diversion hole 5, and the diversion hole 2 and the diversion hole 5 are parallel and side by side; the extrusion mold cavity of the lower die 3 is provided with a die hole, and the die hole includes connected tooth pieces Part 4 and bottom plate part 8; the tooth piece part 4 corresponds to the guide hole 5 of the upper die, and the bottom plate part 8 corresponds vertically to a plurality of diversion holes 2 of the upper die. The upper mold and the lower mold 3 are respectively provided with connecting holes for installing bolts 9, and the contact surface of the upper mold and the lower mold 3 is provided with positioning holes, which are connected b...

Embodiment 2

[0047] The working principle is the same as that of Embodiment 1, the difference is that the number of the upper die is one, and a working belt is also provided at the rear end of the die hole gear part 4, and the gear parts 4 have a total of 44 gears, including There are 42 thin gears in the middle and rear gears on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com