Direct-type sewage source heat pump device

A sewage source heat pump and sewage technology, applied in heat pump, heating method, household heating and other directions, can solve problems such as energy loss, reduce heat pump energy efficiency ratio, high sewage viscosity, etc. The effect of reducing and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with the drawings and embodiments.

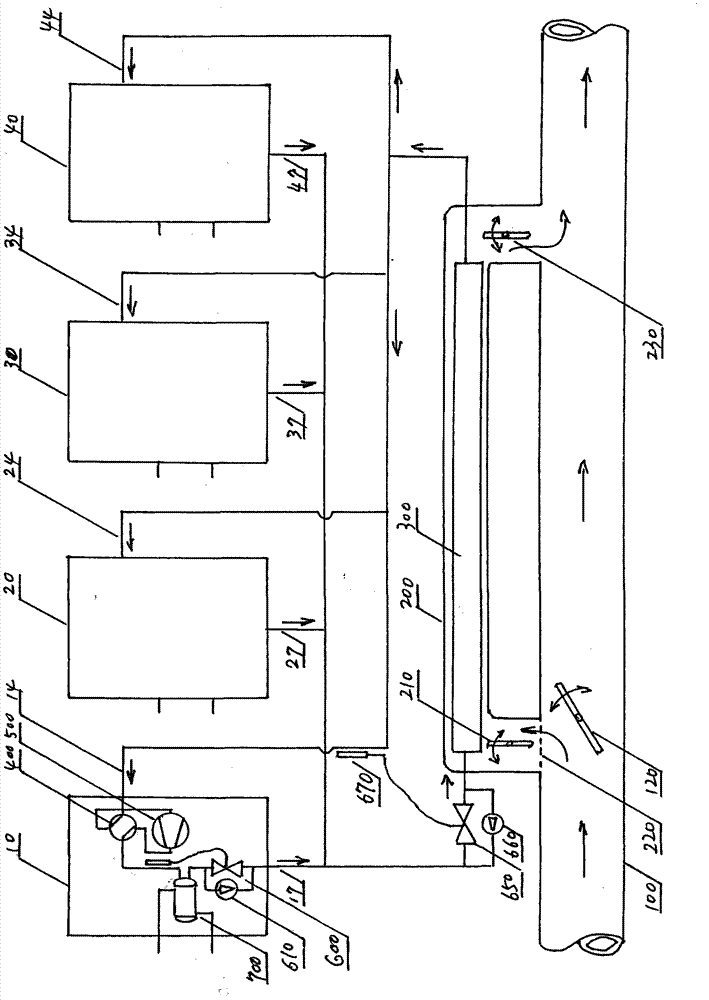

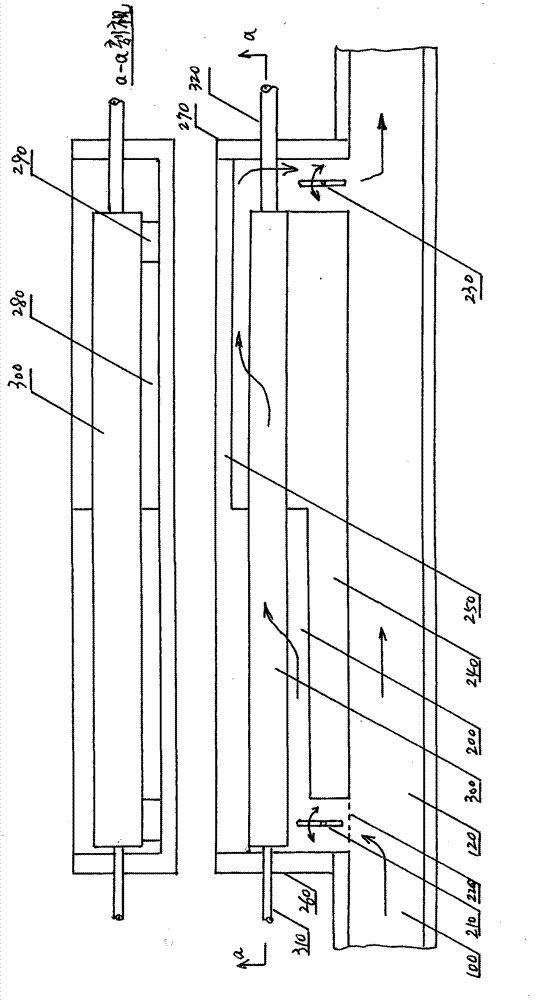

[0064] figure 1 The overall structure diagram of the embodiment of the direct sewage source heat pump device of the present invention is given.

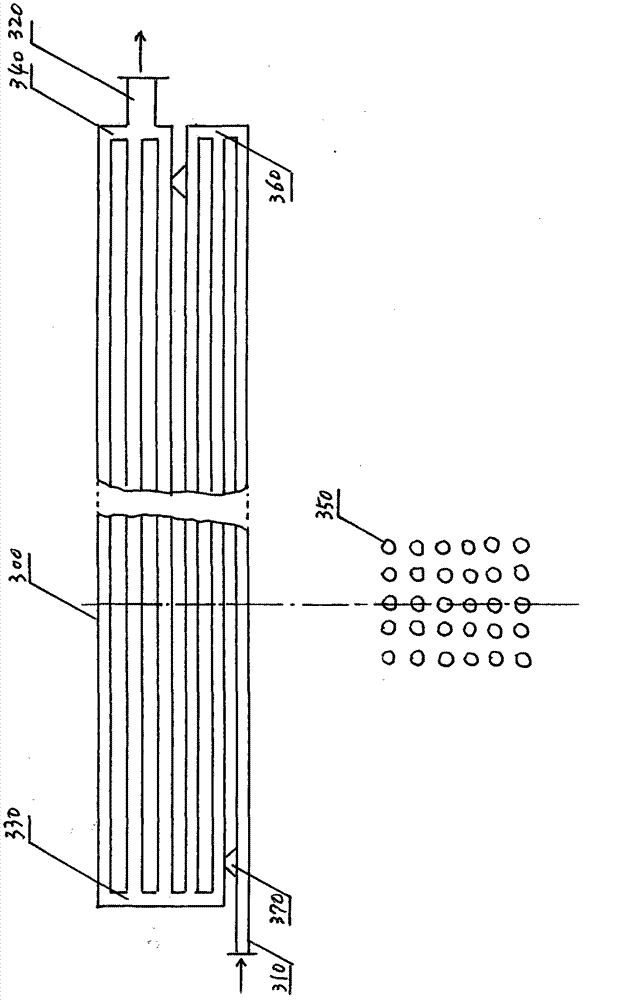

[0065] The overall structure of the embodiment of the direct sewage source heat pump device of the present invention includes: a heat pump host 10, a heat pump host 20, a heat pump host 30, a heat pump host 40, a throttle valve 650, a one-way valve 660, an online sewage / freon heat exchanger 300 and Sinkhole 200. Among them, the heat pump host 10, the heat pump host 20, the heat pump host 30, and the heat pump host 40, the four heat pump hosts have the same structure, and they work in parallel. The number of heat pump hosts may not be four, and the specific number is not limited, but they all work in parallel.

[0066] The embodiment of the direct sewage source heat pump device of the present invention can be used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com