Welding device and copper liner

A welding device and copper lining technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of poor back forming, poor welding quality, wire threading, etc., and achieve the effect of improving quality and reducing molten pool drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a welding device and a copper lining, which can reduce the probability that the molten pool will not fall to the inner wall surface of the pipeline along the groove gap when using the inner butt joint for automatic root welding, so that the occurrence of wire threading, unmelting and The probability of poor backside forming is reduced and the quality of the soldering is improved.

[0023] In order to better understand the above technical solutions, the above technical solutions will be described in detail below with reference to the accompanying drawings and specific embodiments.

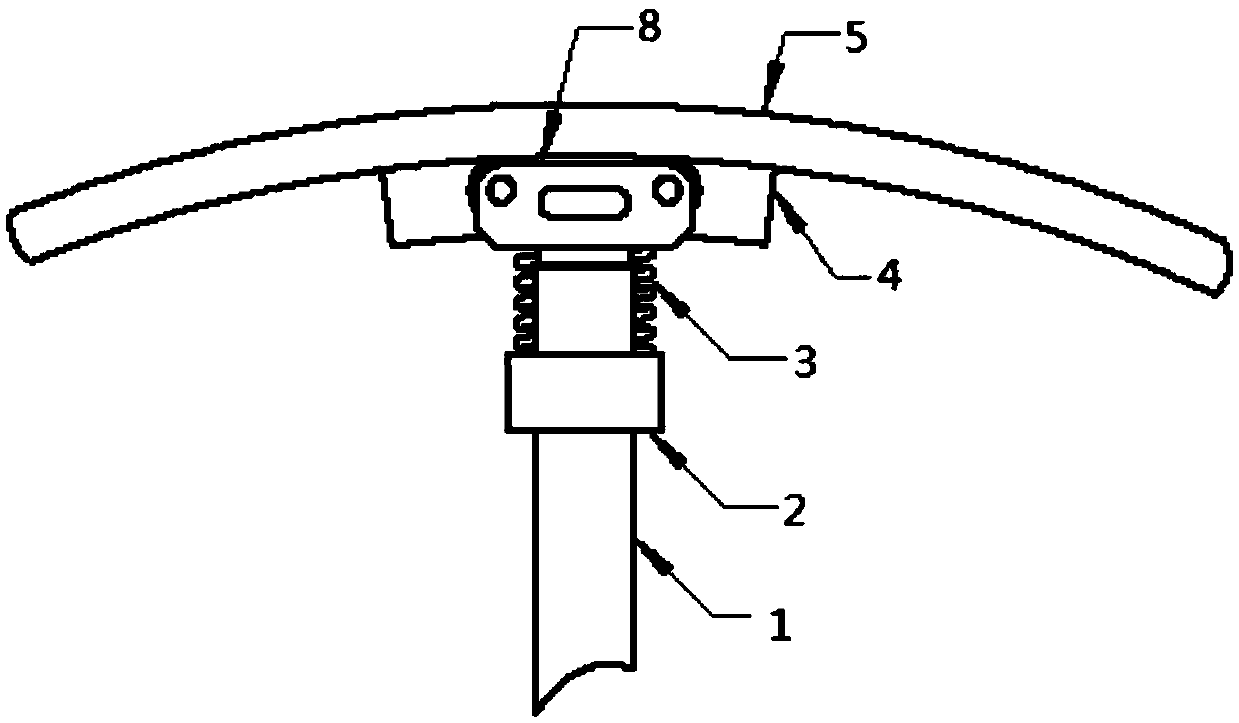

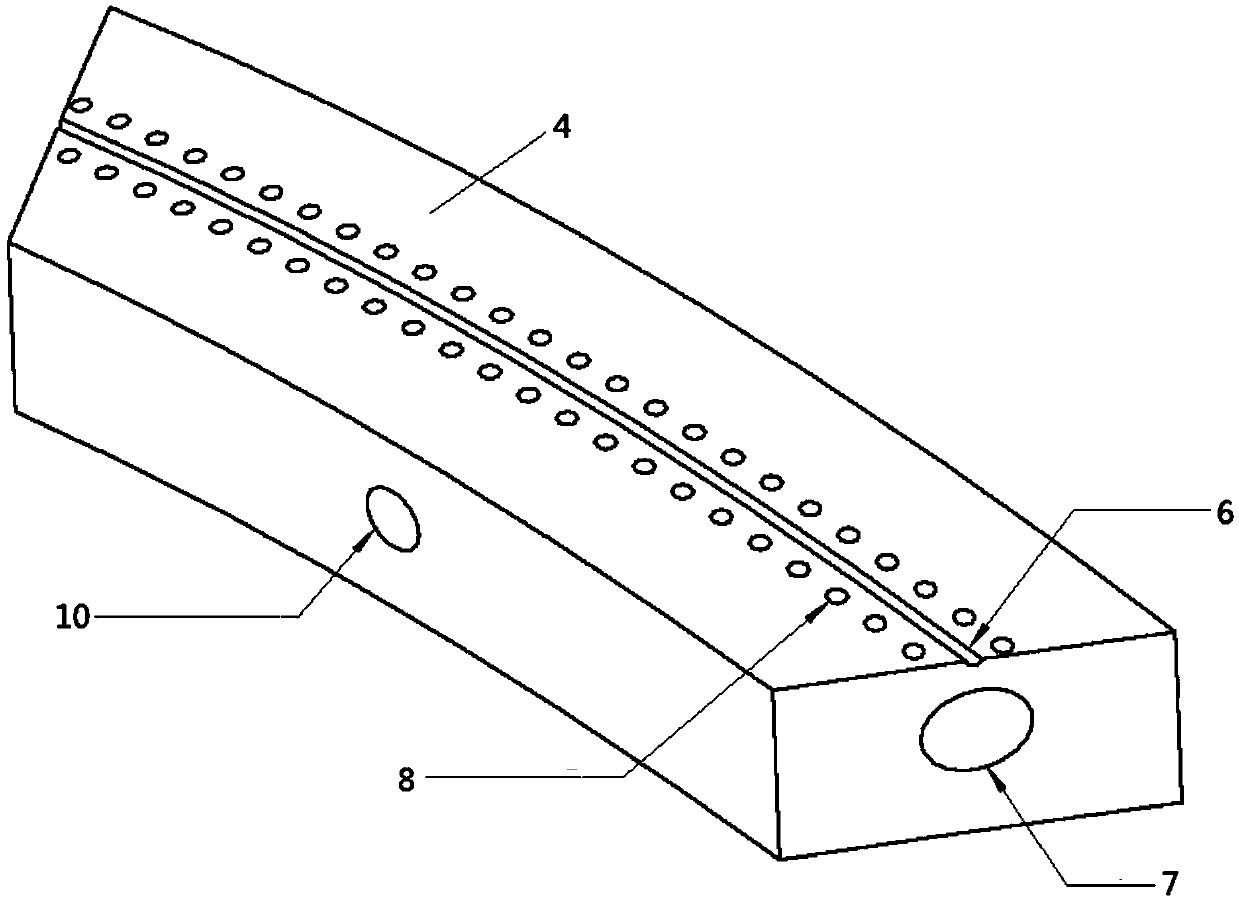

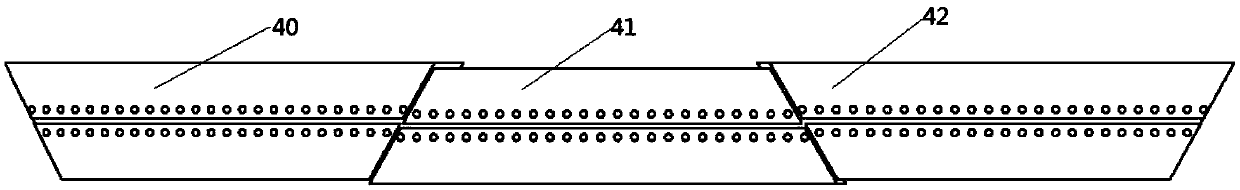

[0024] see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides a welding device, including a mandrel 1, a height adjustment device 2, an elastic member 3, and a copper lining 4, wherein the height adjustment device 2 is arranged on the ejector bar 1, and the copper lining 4 is arranged on the ejector bar. 1, and the copper lining 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com