Welding process for ball mill seal head end cover

A welding process and ball mill technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of workers' operation failing to meet uniform standards, head quality not meeting requirements, and welding quality instability, etc., so as to facilitate placement Positive placement, easy indexing and positioning, and simple actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

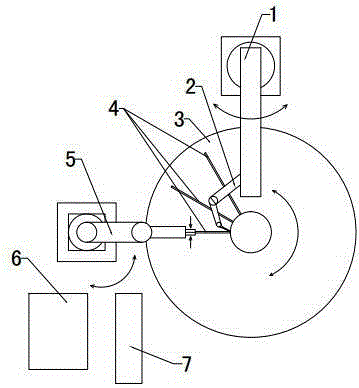

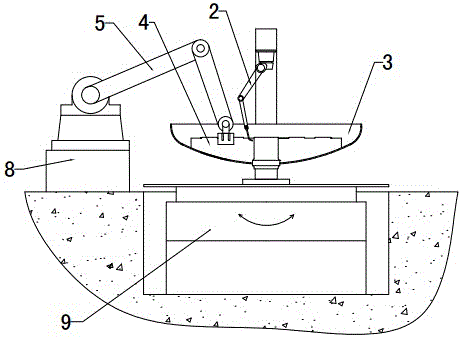

[0024] 1) First, install and fix the head end cap with the opening facing up on the vertical welding positioner through the main shaft passing through the head end cap; use the handling robot to transfer the ribs in the turnover box and place them in the head end cap At the same time, use the welding robot for gas shielded welding to perform spot welding positioning at the contact point between the rib plate and the end cover, and the contact point between the rib plate and the main shaft; start the welding positioner to rotate 20°, and then move the robot Another rib is placed in the next position to be welded in the head end cover, and the above operation is repeated until all the designed number of ribs of the head end cover are spot welded;

[0025] 2) Buckle the head end cover with the rib plate spot welded downwards on the flat workbench, and then put the reinforcement plate with the same arc as the head end cover on the main shaft outside the head end cover, the reinforc...

Embodiment 2

[0028] 1) Firstly, install and fix the head end cover with the opening facing up on the vertical welding positioner through the main shaft passing through the head end cover; use the handling robot to transfer the rib plate in the rib plate turnover box to the head end At the position to be welded in the cover, at the same time, use the welding robot for gas shielded welding to perform spot welding positioning at the contact point between the rib plate and the end cover, and the contact point between the rib plate and the main shaft; start the welding positioner to rotate 30°, and move the robot Then place another rib plate at the next position to be welded in the head end cover, and repeat the above operation until all spot welding of the designed number of rib plates of the head end cover is completed;

[0029] 2) Buckle the head end cover with the rib plate spot-welded downwards on the flat workbench, then put the reinforcing plate with the same arc as the head end cover on ...

Embodiment 3

[0032]1) Firstly, install and fix the head end cover with the opening facing up on the vertical welding positioner through the main shaft passing through the head end cover; use the handling robot to transfer the rib plate in the rib plate turnover box to the head end At the position to be welded in the cover, at the same time, use the welding robot for gas shielded welding to perform spot welding positioning at the contact point between the rib plate and the end cover, and the contact point between the rib plate and the main shaft; start the welding positioner to rotate 18°, and move the robot Then place another rib plate at the next position to be welded in the head end cover, and repeat the above operation until all spot welding of the designed number of rib plates of the head end cover is completed;

[0033] 2) Buckle the head end cover with the rib plate spot welded downwards on the flat workbench, and then put the reinforcement plate with the same arc as the head end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com