Concrete batching plant

A batching machine and concrete technology, applied in batching weighing instrument, clay preparation device, mixing operation control and other directions, can solve the problems of poor concrete quality, low efficiency, inability to separate large stones, etc., and achieve uniform concrete particles and good quality. , the effect of accurate concrete ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

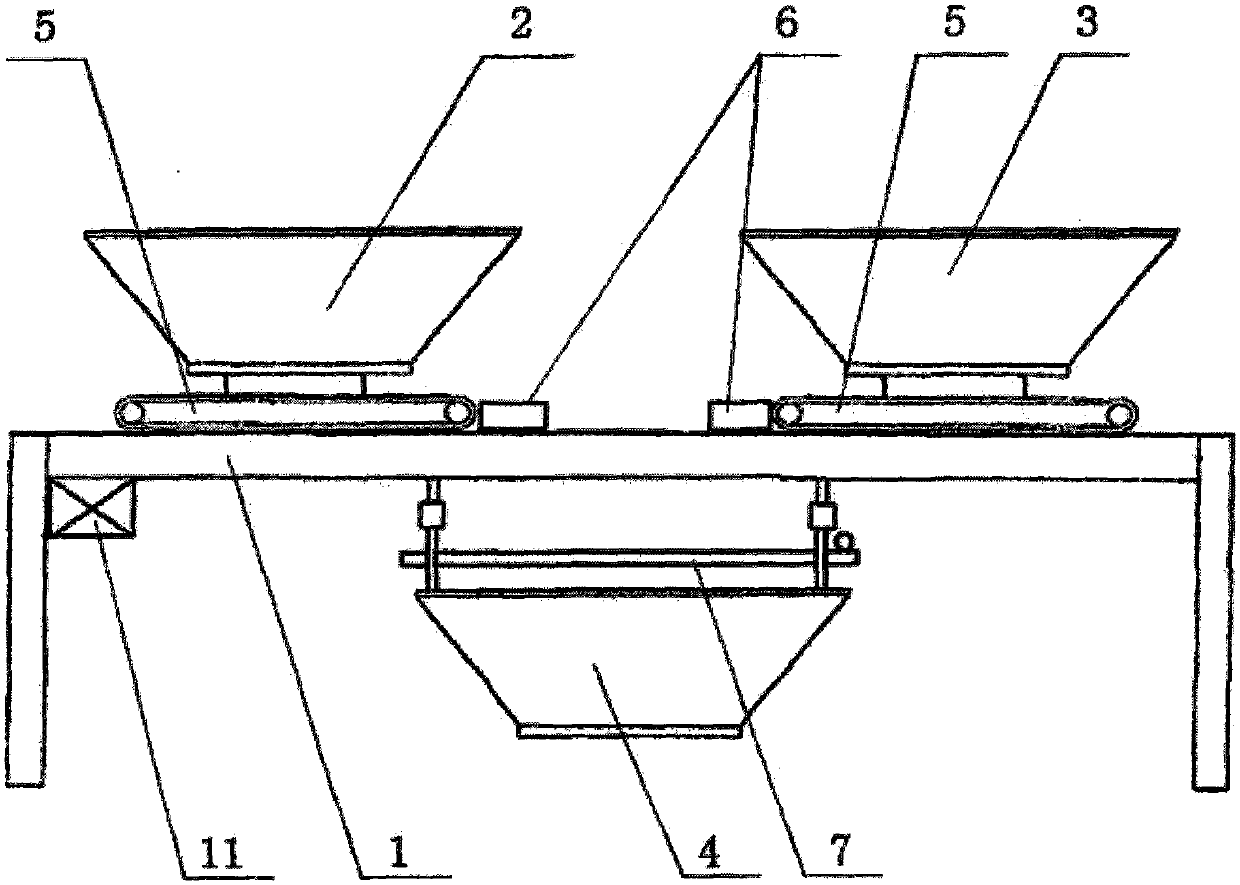

[0012] Such as figure 1 As shown, the present invention is a concrete batching machine, which is composed of a bracket 1, a gravel bucket 2, a sand bucket 3, a storage hopper 4 and other components.

[0013] Wherein, the gravel hopper 2 and the sand hopper 3 are installed above the support 1, and the storage hopper 4 is installed below. A driving motor 11 is arranged at the bottom of the support 1, and the driving motor 11 provides power for the whole concrete batching machine.

[0014] The bottoms of the gravel hopper 2 and the sand hopper 3 are respectively provided with a conveying device 5 for transporting stones and sand. The two conveying devices 5 are oppositely arranged and have opposite directions of movement. One end of each conveying device 5 is provided with a weighing device 6, which can accurately weigh the stones and sand, so as to ensure that the ratio of raw materials for concrete is accurate. The weighing device 6 is located between the two conveying device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com