Crane rotating position non-contact type measurement apparatus and crane rotating position non-contact type measurement method

A non-contact, measuring device technology, used in measuring devices, electrical devices, transportation and packaging, etc., can solve problems such as difficult implementation, deviation of electronic compass output, compass calibration, etc., to achieve convenient debugging and avoid being susceptible to environmental electromagnetic fields. Influence, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

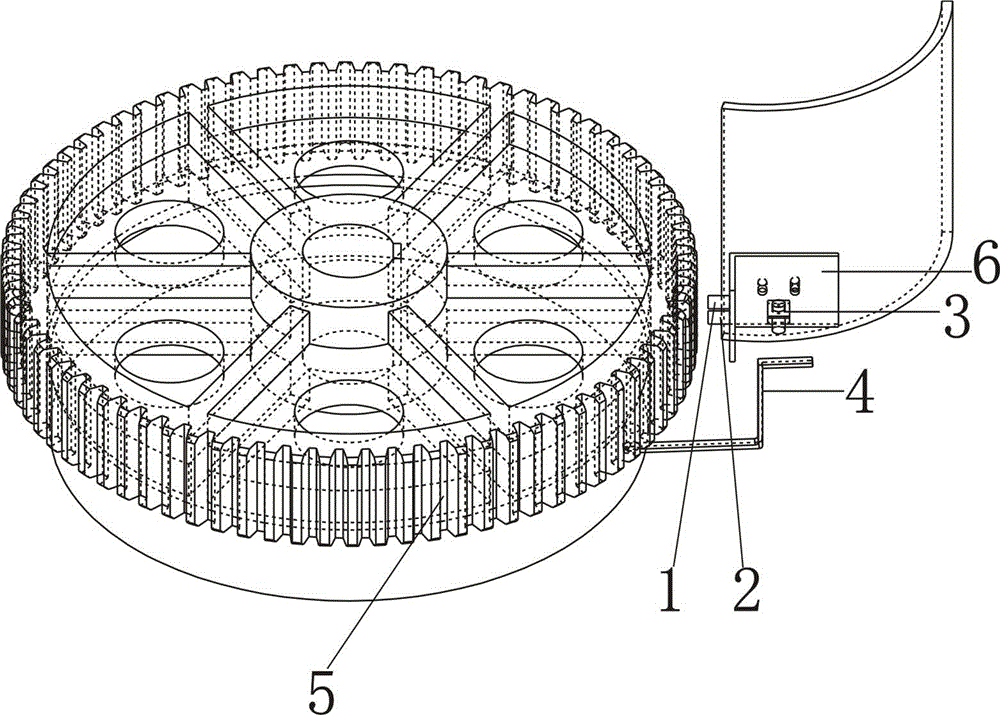

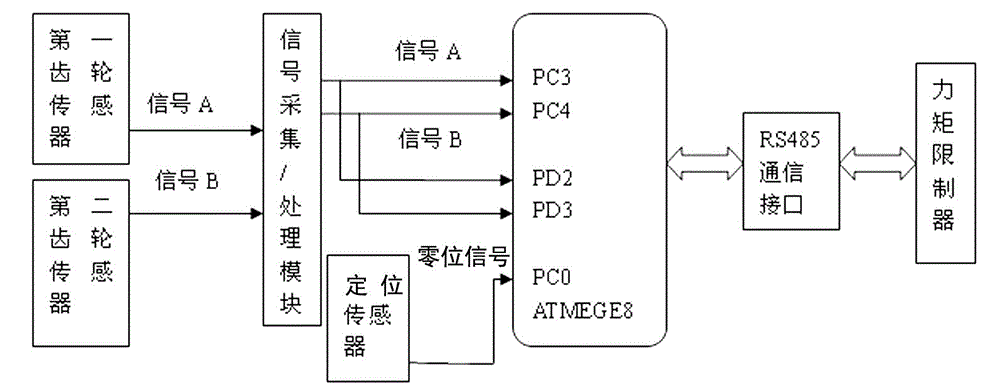

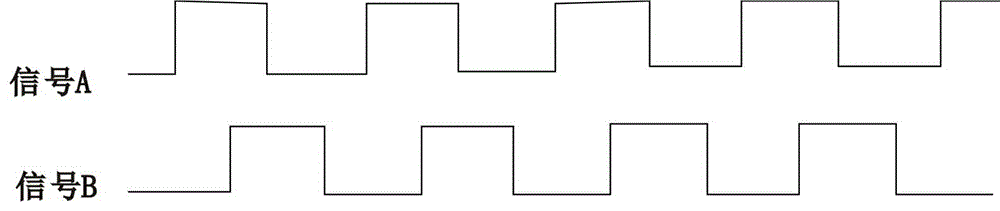

[0020] Such as figure 1 , figure 2 As shown, a non-contact measuring device for the slewing position of a crane includes a first gear sensor 1 , a second gear sensor 2 , a positioning sensor 3 installed on the slewing platform of the crane; and a reflective block 4 fixedly installed. The reflective block 4 is installed under the gear 5 through a fixing nut, and the reflective block 4 is in an inverted L-shape and is perpendicular to the positioning sensor 3 . The reflection block 4 is a steel bar.

[0021] The first gear sensor 1, the second gear sensor 2, and the positioning sensor 3 are all connected to a signal acquisition / processing module, the signal acquisition / processing module is connected to a single-chip processing module, and the single-chip processing module is connected to the torque limiter through the RS-485 communication bus.

[0022] The first gear sensor 1 and the second gear sensor 2 are inductive proximity sensors. The positioning sensor 3 is a reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com