Pinch valve tube, method for manufacturing the same, and pinch valve

A technology of pinch valves and rubber tubes, which is applied in the direction of pipes/pipe joints/fittings, parts in contact between valve elements and valve seats, pipes, etc. Long-term problems, to achieve high productivity, excellent response speed, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072]

[0073] 30 parts by mass of carbon black, calcium hydroxide 6 parts by mass and 3 parts by mass of magnesium salt were kneaded, molded into a tube at 182°C after kneading, and at the same time made a primary crosslinking to make a fluororubber tube.

[0074]

[0075] As the polyol-based crosslinking agent, two substances, bisphenol AF and a salt having a mass ratio of benzyltriphenylphosphonium and bisphenol AF of 1:1, were used in combination at a mass ratio of 1.52 / 0.48.

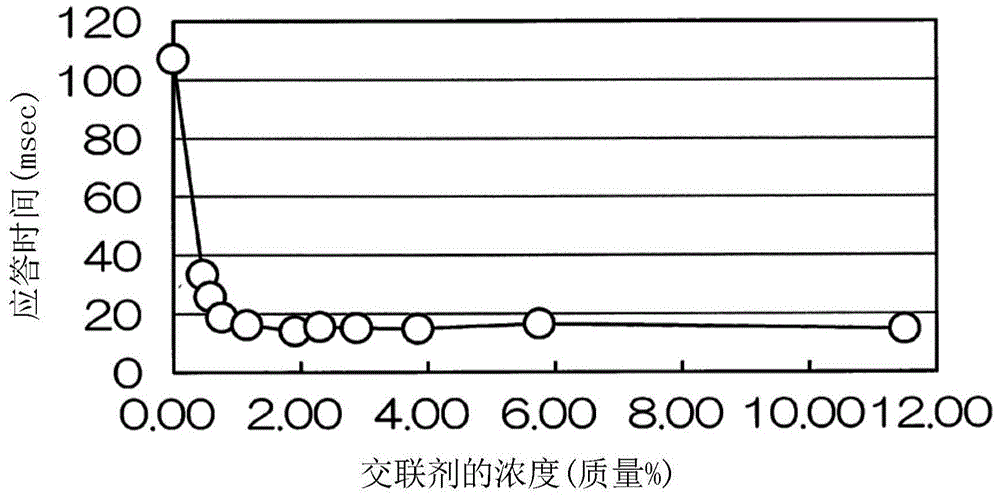

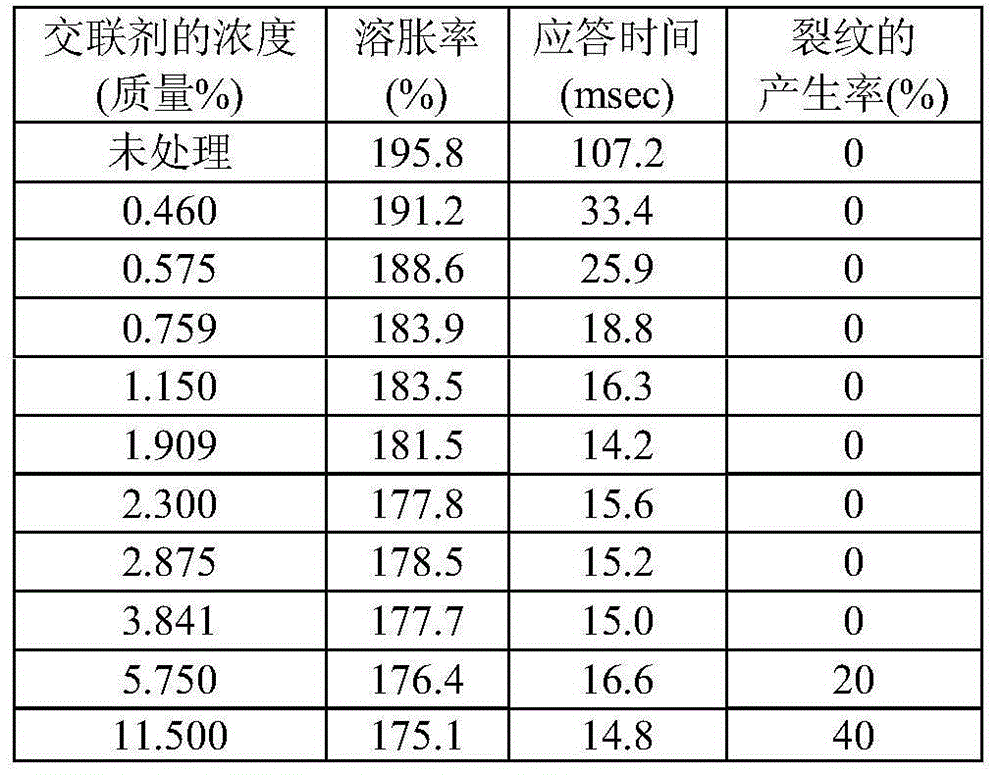

[0076] Furthermore, the two polyol-based crosslinking agents were dissolved in a mixed solvent with a mass ratio of acetone and methanol of 1 / 1 at the concentrations shown in Table 1 below to prepare a crosslinking agent solution.

[0077]

[0078] According to the way that the cross-linking agent solution enters the flow path, immerse the previously prepared fluororubber tube as a whole into the cross-linking agent solution prepared above, and lift it up after standing at room temperature fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com