Heat exchange assembly, heat exchanger and refrigerating system

A technology of heat exchange components and heat exchangers, which is applied in the field of heat exchangers, refrigeration systems, and heat exchange components. It can solve problems such as low heat exchange efficiency, gaps, and difficult processing, so as to improve heat exchange efficiency and strengthen Compression capacity, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

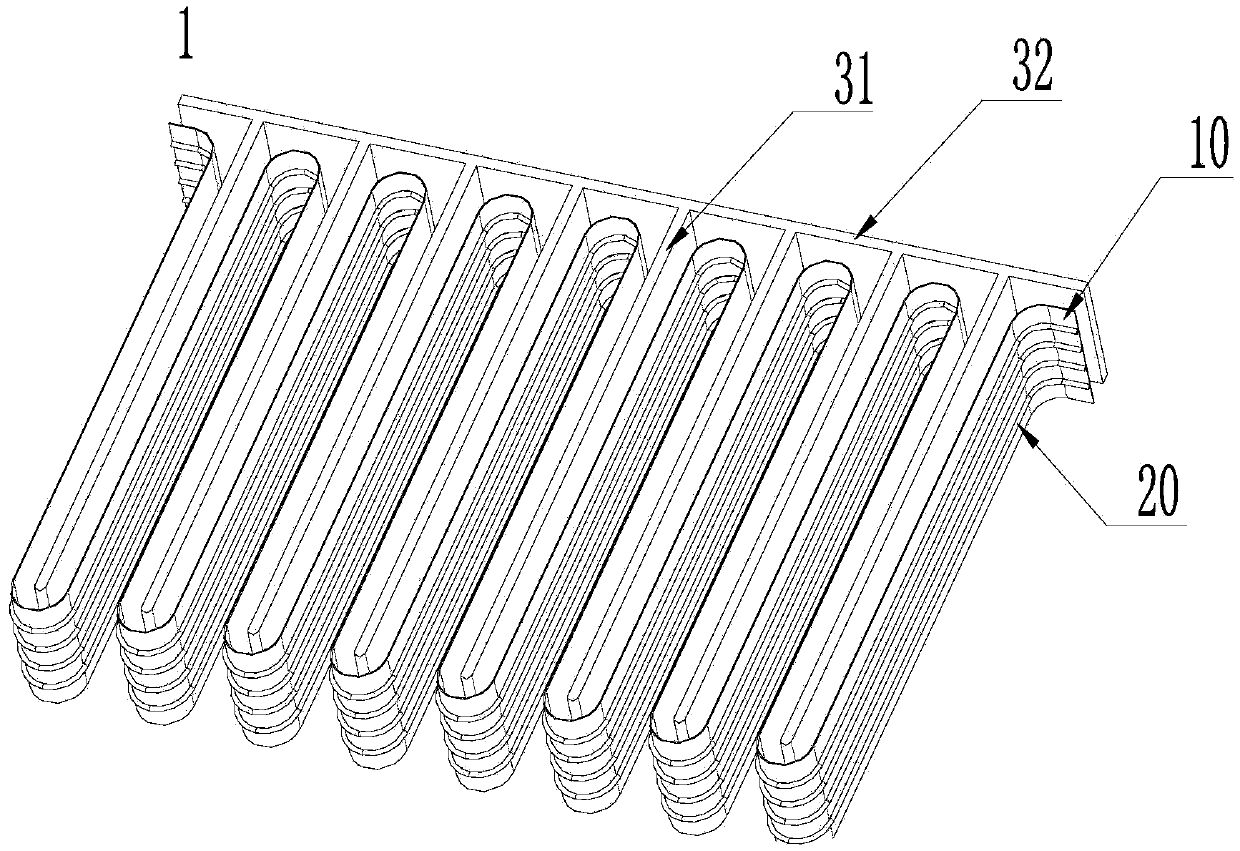

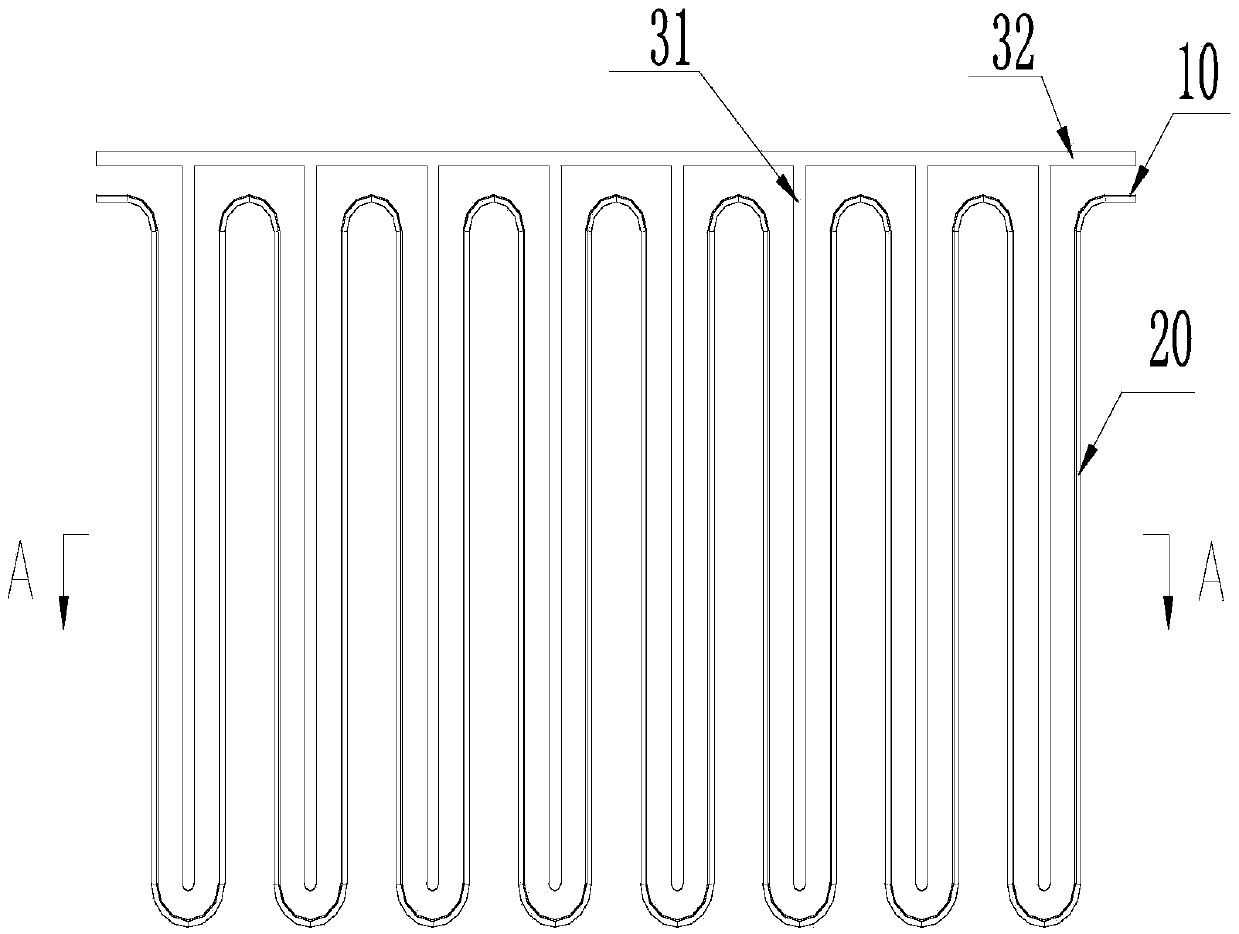

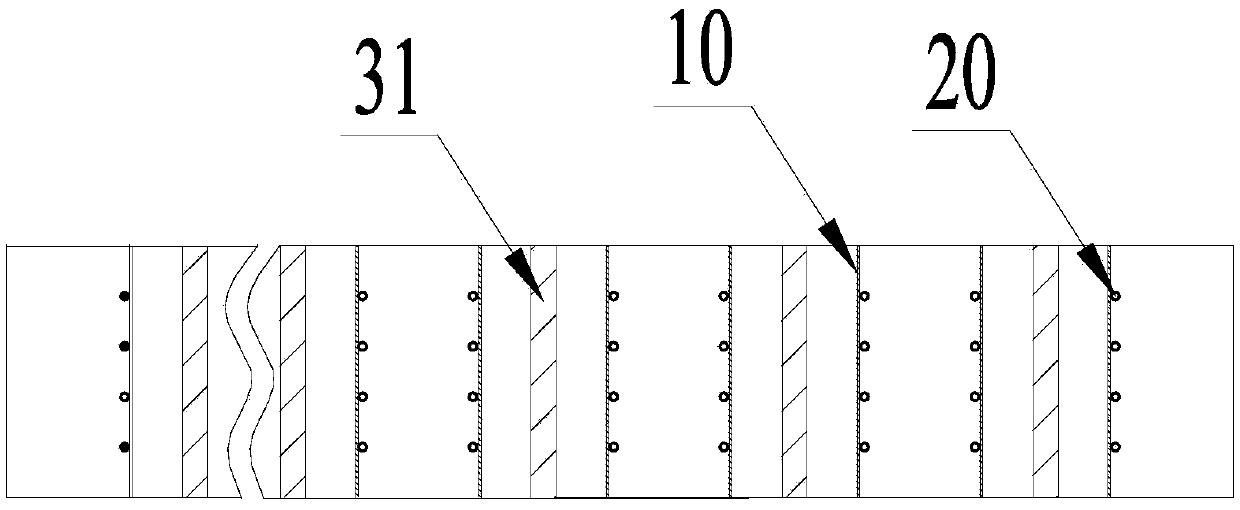

[0026] Such as figure 1 As shown, the heat exchange assembly 1 according to the present invention includes a heat conduction plate 10 , a refrigerant pipe 20 attached to the first side of the heat conduction plate 10 , and a separator for cooling liquid forming a serpentine shape with the second side of the heat conduction plate 10 . By arranging the refrigerant and the cooling liquid on both sides of the heat conduction plate 10, the refrigerant and the cooling liquid are separated, preventing the refrigerant pipe 20 from being corroded by the cooling liquid, and improving the service life of the heat exchange component 1; at the same time, the refrigerant pipe 20 is attached to the snake On the heat conducting plate 10, the serpentine cooling liquid path formed by the partition plate and the heat conducting plate 10 makes the heat exchange distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com