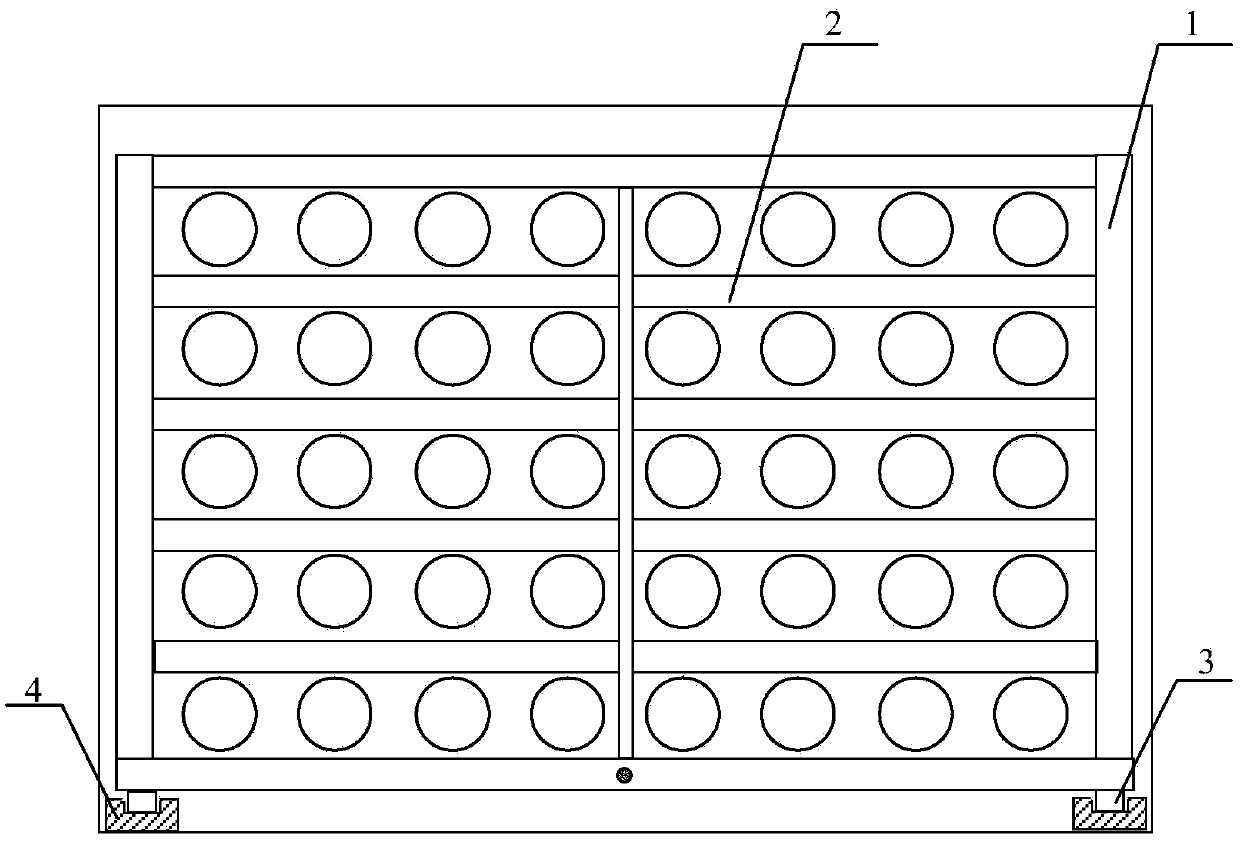

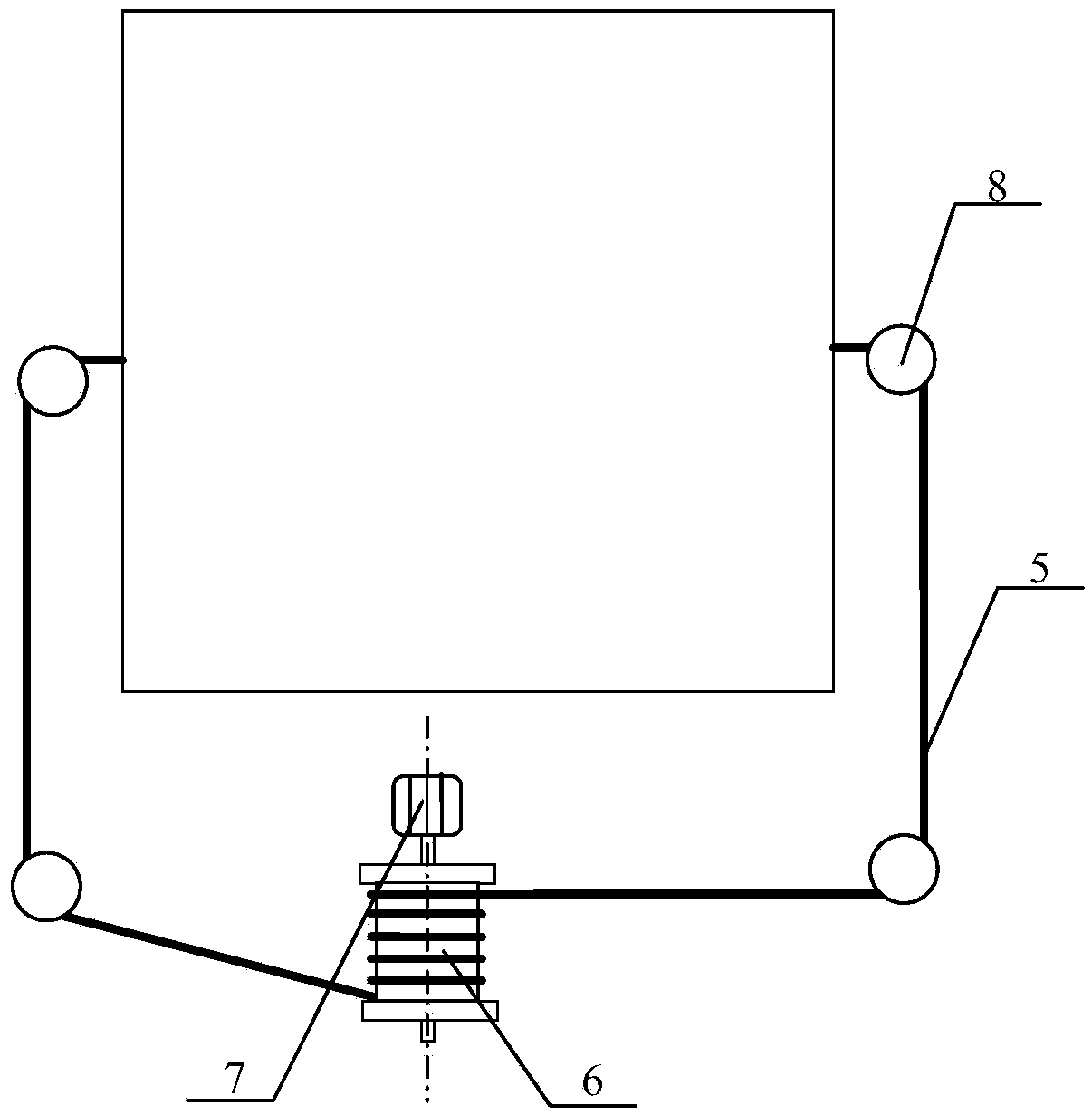

Dust removing method for tube-type heat exchanger and dust removing device for tube-type heat exchanger

The technology of a tubular heat exchanger and an ash cleaning device is applied in the field of metallurgy, which can solve the problems of reducing the heat exchange efficiency of the tubular heat exchanger, and achieve the effect of reducing the thickness and ensuring the heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, the cleaning knife 2 includes a mounting plate and a knife head fixedly connected to the mounting plate. ;

Embodiment 2

[0055] Embodiment 2, the cleaning knife 2 includes a mounting plate and a cutter head fixedly connected with the mounting plate, the cutter head is a circular cutter head, and the mounting plate is connected with the vertical plate;

Embodiment 3

[0056] Embodiment 3, the cleaning knife 2 is a rectangular plate, and the length of the rectangular plate is equal to the width of the tubular heat exchanger.

[0057] The dust-cleaning knife 2 in Embodiment 1 and Embodiment 3 can only scrape one side of the heat exchange tube during a single scraping process, and the dust-cleaning knife 2 in Embodiment 2 can It is possible to scrape the entire circumference of the heat exchange tube.

[0058] In order to ensure the stable connection of the guide rail 3, preferably, the guide rail 3 is connected to the bottom plate of the tube heat exchanger, and the installation of the dust cleaning device of the tube heat exchanger can be realized without the help of other devices, thereby reducing the cost of the tube heat exchanger. The cost and volume of the cleaning device. In order to facilitate the connection between the tube heat exchanger dust removal device and the bottom plate, preferably, the tube heat exchanger and the bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com